Cigarette packet box gluing and folding device

A folding device and cigarette pack technology, which is applied in packaging, transportation and packaging, and box making operations, can solve the problems of complex machinery and equipment, long drying time, and long size, so as to simplify the follow-up process and improve the bonding effect , the effect of large bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

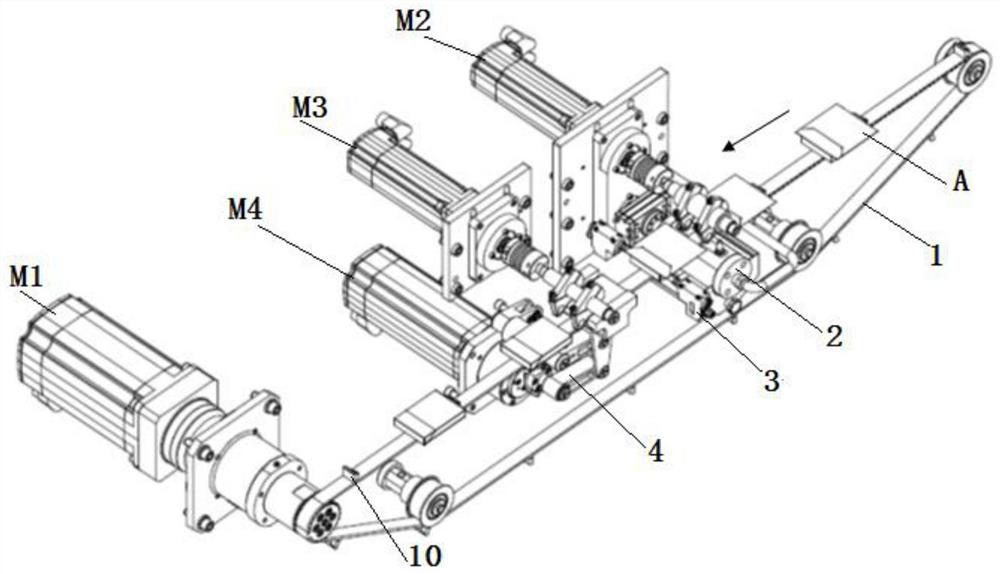

[0065] Such as image 3 As shown, the gluing and folding device for cigarette packs includes a timing belt 1, a cold glue spraying device 2, a hot melt glue spraying device 3 and a movable folding device 4;

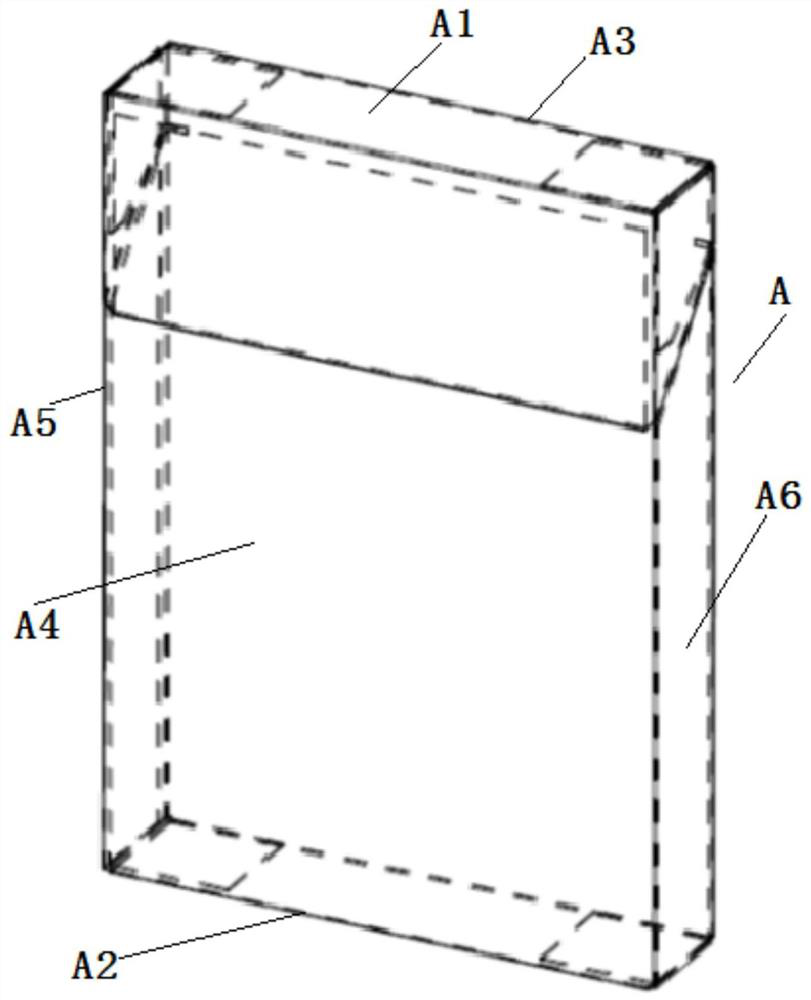

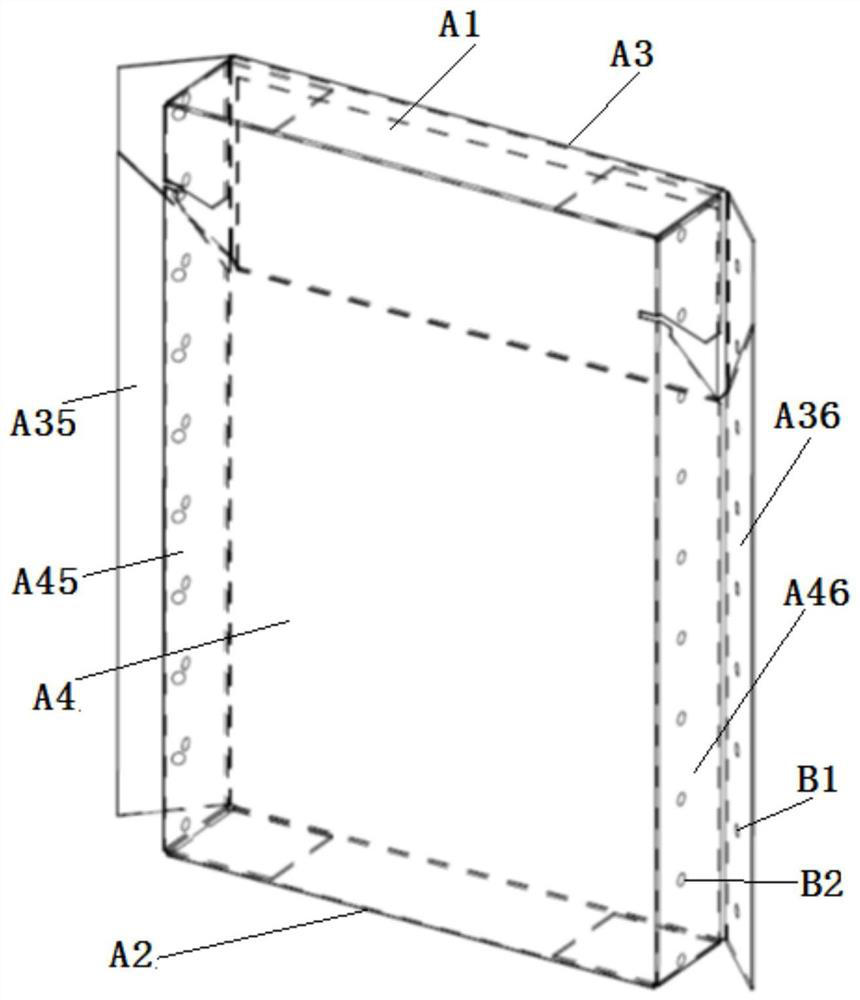

[0066] Such as figure 2 As shown, the main body of the cigarette packet box to be processed is a cuboid, and the top surface A3 of the main body has a left to-be-folded surface A35 unfolded toward the left side of the main body left side A45 and a right side to be folded toward the right side of the main body right side A46. Folding surface A36;

[0067] The cigarette packet box to be processed is placed on the timing belt 1, the bottom surface A4 of the main body of the cigarette packet box to be processed is attached to the timing belt 1 downward, and the left side to be folded A35 and the right side to be folded A36 protrude out from the left and right sides of the timing belt 1;

[0068] The synchronous belt 1 drives the cigarette pack to be processed to move from ...

Embodiment 2

[0075] Based on the gluing and folding device for cigarette packs in Embodiment 1, the synchronous belt 1 is driven by the conveying servo motor M1 to move forward intermittently or continuously.

[0076] Preferably, the conveying servo motor M1 is arranged in front of the cold glue spraying device 2 , the hot melt glue spraying device 3 and the movable folding device 4 .

[0077] Preferably, the synchronous belt 1 is provided with lugs 10;

[0078] The cigarette pack box to be processed placed on the synchronous belt 1, the back side A2 of its main body leans against a lug 10;

[0079] The cigarette pack box to be processed moves forward under the promotion of the synchronous belt 1 lug 10 .

[0080] Preferably, the left and right width of the main body of the cigarette pack to be processed is 0.9 to 2.8 times the width of the timing belt 1 .

[0081] Preferably, the left and right width of the main body of the cigarette pack to be processed is 1 to 2.2 times the width of t...

Embodiment 3

[0083] Based on the cigarette pack case gluing and folding device of Embodiment 1, such as Figure 4 As shown, the cold glue spraying device 2 includes a rotating cylinder 21, a cylindrical valve body 22 and two left and right cold glue guns 23;

[0084] The rotary cylinder 21 is used to drive the cylindrical valve body 22 to rotate;

[0085] The cylindrical valve body 22 is placed under the synchronous belt 1;

[0086] Two left and right cold glue guns 23 are installed in the cylindrical valve body 22;

[0087] The rotating cylinder 21 can drive the cylindrical valve body 22 to rotate so that the cold glue injection ports of the left and right cold glue guns 23 face upward and are respectively located on both sides of the advancing path of the main body of the cigarette pack to be processed;

[0088] When the cigarette pack box to be processed moves forward through the cold glue spraying station, the left and right cold glue guns 23 spray cold glue points B1 vertically from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com