High voltage LED chip preparation method being able to form isolated slot through scribing and corrosion

An LED chip and isolation groove technology, applied in the field of optoelectronics, can solve the problems of complex process flow, short-circuit failure, complex preparation process, etc., and achieve the effect of simplifying the process flow, solving short-circuit failure and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

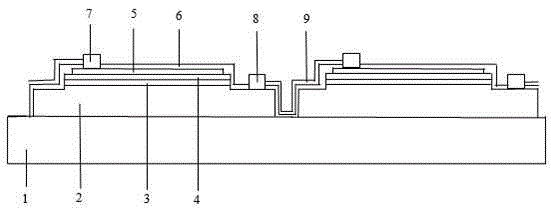

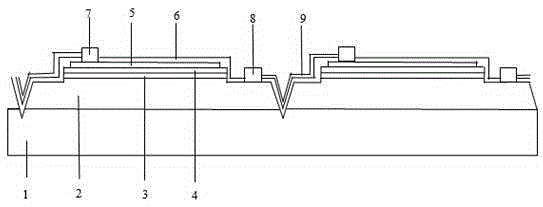

[0029] The high-voltage LED chip in the present invention, such as figure 2 As shown, it includes a sapphire substrate 1, an n-type GaN layer 2, a quantum well layer 3, a p-type GaN layer 4, an ITO transparent conductive film layer 5 and a passivation layer 6 arranged from bottom to top. Layer 5, n-type GaN layer 2 and passivation layer 6 are respectively provided with p-electrode 7, n-electrode 8 and metal lead 9.

[0030] The preparation method of the above-mentioned high-voltage LED chip comprises the following steps:

[0031] (1) In the reaction chamber of the metal-organic chemical vapor deposition equipment, the n-type GaN layer 2, the quantum well layer 3 and the p-type GaN layer 4 are sequentially grown on the substrate 1 to obtain a GaN-based epitaxial wafer. Substrate 1 may be sapphire, SiC or silicon.

[0032] (2) Use the existing ICP dry etching method to etch the mesa structure along the p-type GaN layer 4 to the n-type GaN layer 2 of the GaN-based epitaxial wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com