Sludge dewatering conditioner and sludge dewatering method

A sludge dehydration and conditioning agent technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of simultaneous removal and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

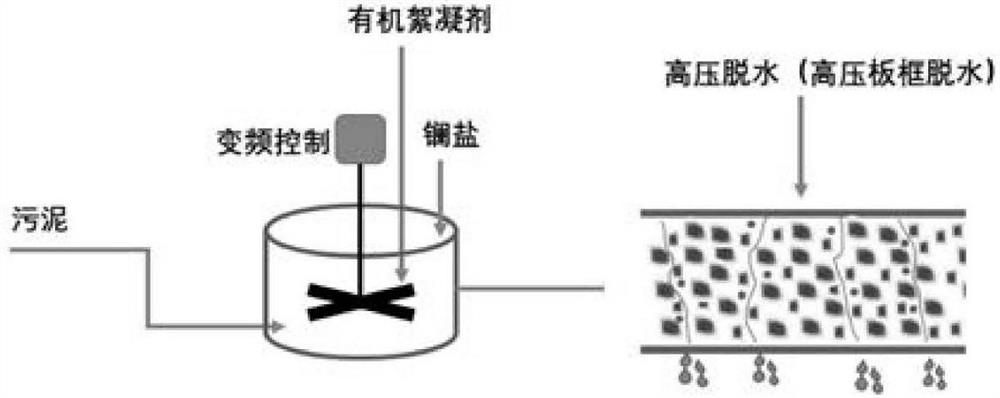

Method used

Image

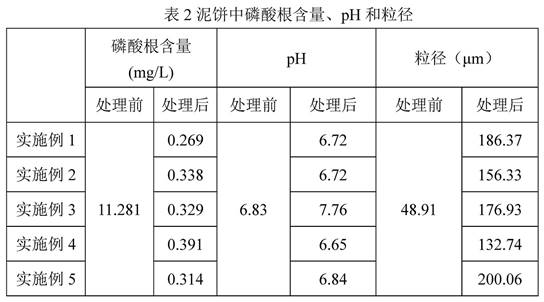

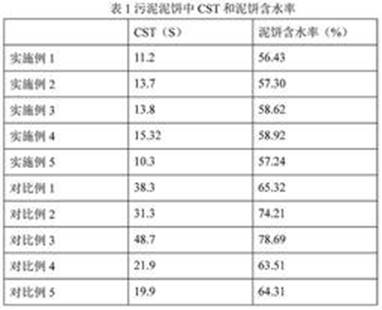

Examples

Embodiment 1

[0023] This embodiment provides a sludge dewatering conditioner, comprising 4.5g LaCl 3 ·7H 2 O and 1.5 g of cationic polyacrylamide.

[0024] The present embodiment also provides a method for dewatering sludge, using the above conditioning agent, comprising the following steps:

[0025] (1) Dissolve lanthanum chloride heptahydrate into an aqueous solution with a concentration of 100 g / L;

[0026] (2) 45mL of step (1) solution was added to 5kg of sludge with a moisture content of 97% within 3min at a speed of 200rpm (that is, 30 mg / g TSS was added to the sludge), and then reacted for 10min;

[0027] (3) Continue to add 1.5g of cationic polyacrylamide (that is, add 10 mg / g TSS to the sludge) at a speed of 200 rpm, and stir for 2 min; then reduce the speed to 40 rpm and continue to stir for 12 min;

[0028] (4) Press filter the above sludge under the pressure of 0.6Mpa for 50min to obtain a dewatered sludge filter cake.

Embodiment 2

[0030] This embodiment provides a sludge dewatering conditioner, comprising 7.5 g La (NO 3 ) 3 ·6H 2 O and 0.75 g chitosan.

[0031] The present embodiment also provides a method for dewatering sludge, using the above conditioning agent, comprising the following steps:

[0032] (1) Dissolve lanthanum nitrate hexahydrate into an aqueous solution with a concentration of 120 g / L;

[0033] (2) 62.5mL of step (1) solution was added to 5kg of sludge with a moisture content of 97% within 5min at a speed of 100rpm (that is, 50 mg / g TSS was added to the sludge), and then reacted for 5min;

[0034] (3) Continue to add 0.75g of chitosan (that is, add 5 mg / g TSS to the sludge) at a speed of 100rpm, and stir for 3min; then reduce the speed to 20rpm, and continue to stir for 15min;

[0035] (4) Press filter the above sludge under the pressure of 0.5Mpa for 60min to obtain a dewatered sludge filter cake.

Embodiment 3

[0037] This embodiment provides a sludge dewatering conditioner, comprising 1.5g LaCl 3 ·7H 2 O and 2.25 g cationic starch.

[0038] The present embodiment also provides a method for dewatering sludge, using the above conditioning agent, comprising the following steps:

[0039] (1) Dissolve lanthanum chloride heptahydrate into an aqueous solution with a concentration of 80 g / L;

[0040] (2) 19mL of step (1) solution was added to 5kg of sludge with a moisture content of 97% within 5min at a speed of 300rpm (that is, 10 mg / g TSS was added to the sludge), and then reacted for 20min;

[0041] (3) Continue to add 2.25g of cationic starch (that is, add 15 mg / g TSS to the sludge) at a speed of 300 rpm, and stir for 1.5 min; then reduce the speed to 60 rpm and continue to stir for 10 min;

[0042] (4) Press filter the above sludge under the pressure of 0.8Mpa for 40min to obtain the dehydrated sludge filter cake.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com