High-strength medical gel material and preparation method thereof

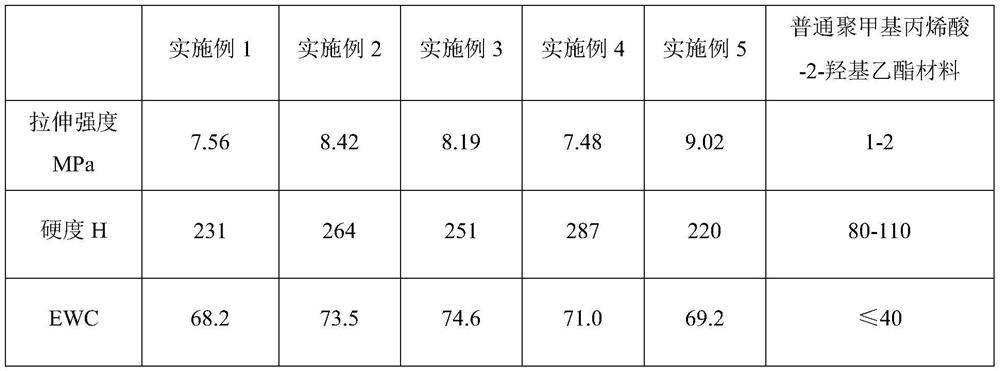

A gel material and high-strength technology, which is applied in the field of high-strength medical gel material and its preparation, can solve the problems of poor PHEMA strength and water absorption capacity, and achieve the effect of improved toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to parts by weight, dissolve 1 part of hyaluronic acid in deionized water to obtain a colloidal solution; add 98.7 parts of poly-2-hydroxyethyl methacrylate to the above colloidal solution, and stir at 85°C for 6 hours to obtain a polymer mucus Remove bubbles from the polymer mucus under ultrasonic conditions, pour it into a Teflon reactor for freezing (-20°C)-thawing (35°C) cycle reaction for 1 hour (freezing and thawing each for 0.5h); Put the gel in an oven and heat it to 125°C for 1.5 hours; take 0.3 parts of CaCl 2 Prepare CaCl with a concentration of 0.08mol / L 2 solution, the dried gel was immersed in CaCl 2 After soaking in the solution for 40 hours, wash with deionized water to obtain PHEMA / HA-Ca 2+ Material; PHEMA / HA-Ca 2+ After the material is subjected to freezing (-20°C)-thawing (35°C) cycle reaction in a Teflon reactor, it is placed in an oven and heated to 125°C and then kept for 2 hours to obtain a high-strength medical gel material.

Embodiment 2

[0029] According to parts by weight, dissolve 1.2 parts of hyaluronic acid in deionized water to obtain a colloid solution; add 98.4 parts of poly-2-hydroxyethyl methacrylate to the above colloid solution, and stir at 80°C for 5 hours to obtain a polymer mucus Remove bubbles from the polymer mucus under ultrasonic conditions, pour it into a Teflon reactor for freezing (-25°C)-thawing (32°C) cycle reaction for 1 hour (freezing and thawing each for 0.5h); Put the gel in an oven and heat it to 130°C for 2 hours; take 0.4 parts of CaCl 2 Prepare CaCl with a concentration of 0.1mol / L 2 solution, the dried gel was immersed in CaCl 2 After soaking in the solution for 48 hours, wash with deionized water to obtain PHEMA / HA-Ca 2+ Material; PHEMA / HA-Ca 2+ After the material is subjected to freezing (-25°C)-thawing (32°C) cycle reaction in a Teflon reactor, it is placed in an oven and heated to 130°C and then kept for 2 hours to obtain a high-strength medical gel material.

Embodiment 3

[0031] According to parts by weight, dissolve 0.8 parts of hyaluronic acid in deionized water to obtain a colloidal solution; add 98.9 parts of poly-2-hydroxyethyl methacrylate to the above colloidal solution, and stir at 90°C for 7 hours to obtain a polymer mucus Remove bubbles from the polymer mucus under ultrasonic conditions, pour it into a Teflon reactor for freezing (-18°C)-thawing (38°C) cycle reaction for 1.5 hours (freezing and thawing each 0.75h); Put the gel in an oven and heat it to 135°C for 2.5 hours; take 0.3 parts of CaCl 2 Prepare CaCl with a concentration of 0.15mol / L 2 solution, the dried gel was immersed in CaCl 2 After soaking in the solution for 60 hours, wash with deionized water to obtain PHEMA / HA-Ca 2+ Material; PHEMA / HA-Ca 2+ After the material is frozen (-18°C)-thawing (38°C) cycle reaction in a Teflon reactor, it is placed in an oven and heated to 135°C and then kept for 2.5 hours to obtain a high-strength medical gel material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com