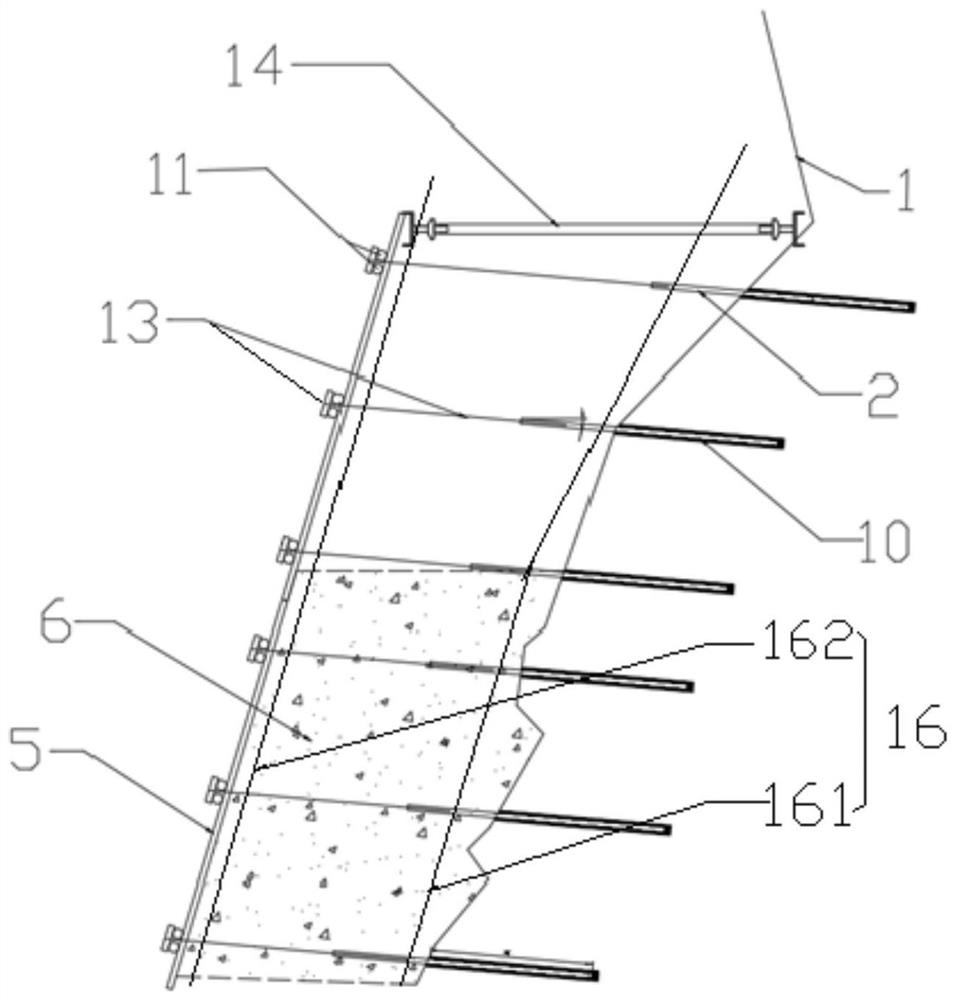

Cantilever support platform, supporting retaining wall and construction method

A construction method and technology for supporting platforms, which are applied in the fields of excavation, artificial islands, earthwork drilling, etc., can solve the problems of difficult erection of high-altitude platform supports, difficulty in supplying raw materials, and high safety risks, so as to overcome construction difficulties, complete quickly and efficiently, and safely. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

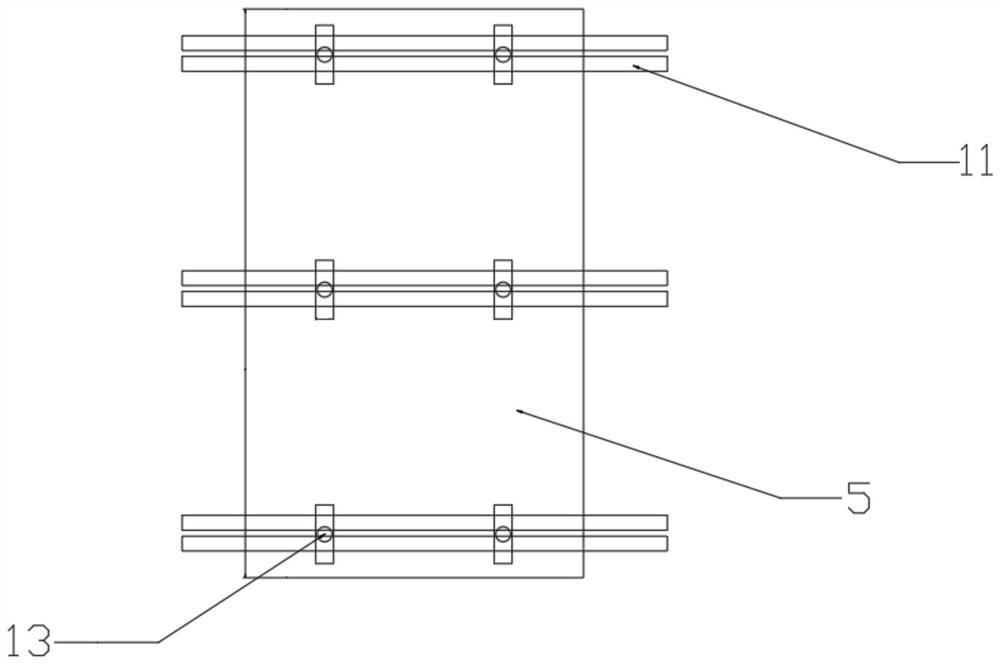

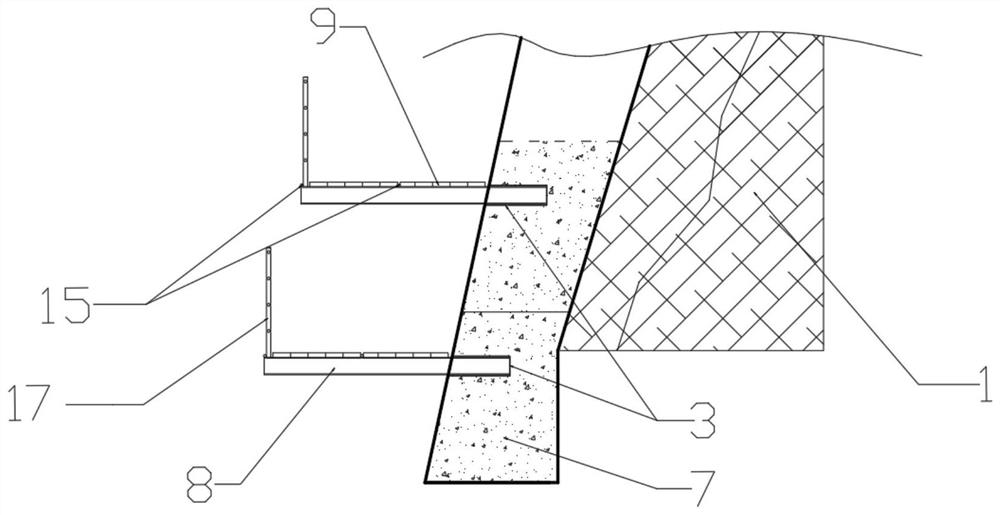

Method used

Image

Examples

Embodiment 1

[0041] This example is a dangerous rock fall renovation project in a tunnel. The renovation project belongs to the upper cliff + lower slope landform. The cliff is formed by a fault and is about 150m higher than the railway shoulder. The horizontal distance from the tunnel entrance is about 115m, and the steep slope is about 80. ~85°, the natural slope of the slope is 30-50°, and the relative height difference is about 85m.

[0042] 1. Overview of working conditions

[0043] The lower part of the dangerous rockfall at the entrance of a tunnel is mainly the poplar forest tunnel entrance, the main body of a super-large bridge, all the anchors and fastening systems for the construction of the main span of the bridge, concrete mixing stations, steel processing sheds, staff dormitories, construction access roads, etc. These main works, supporting facilities and temporary facilities are all located within the range of falling dangerous rocks and falling rocks, and the surrounding en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com