Integrated self-lubricating carrier roller structure for medium-thickness plate roller type cooling bed

A roller-type, self-lubricating technology, applied in the direction of the cooling bed, bearings, shafts, etc., can solve the problems of increased scrap rate, large gap between the shaft sleeve and the idler shaft, and insufficient lubrication, so as to prolong the service life and prevent dust from entering Effects within the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited to the accompanying drawings.

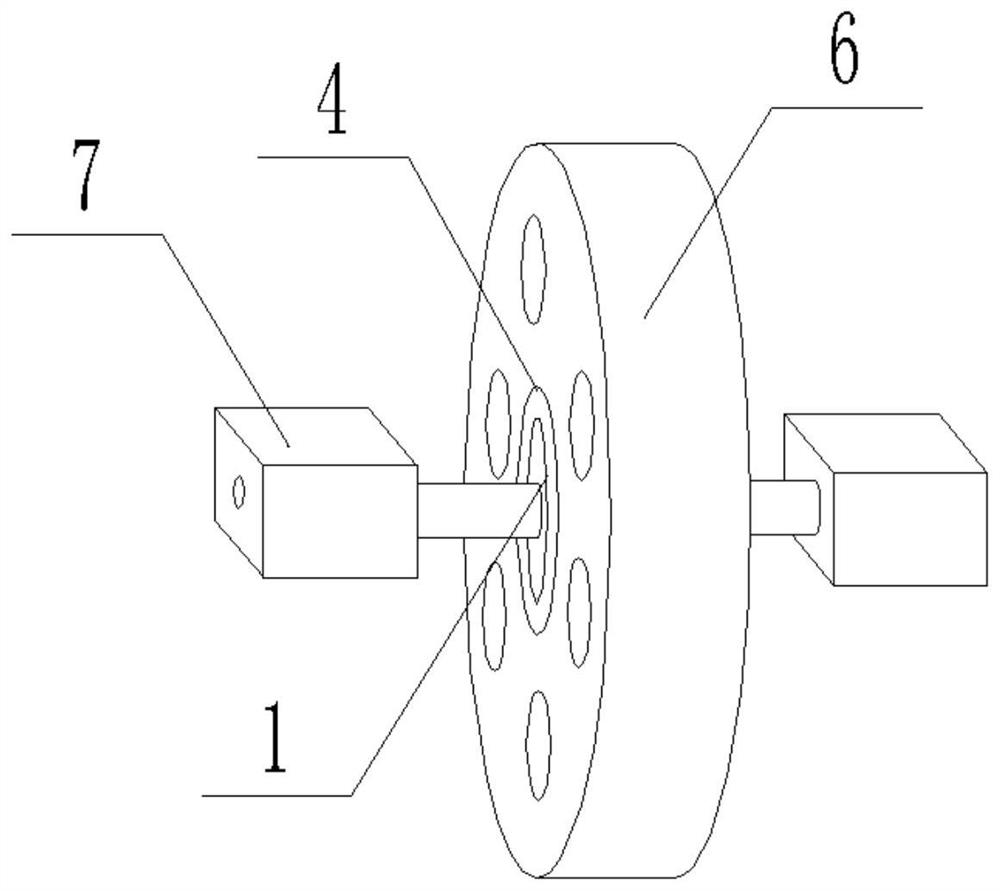

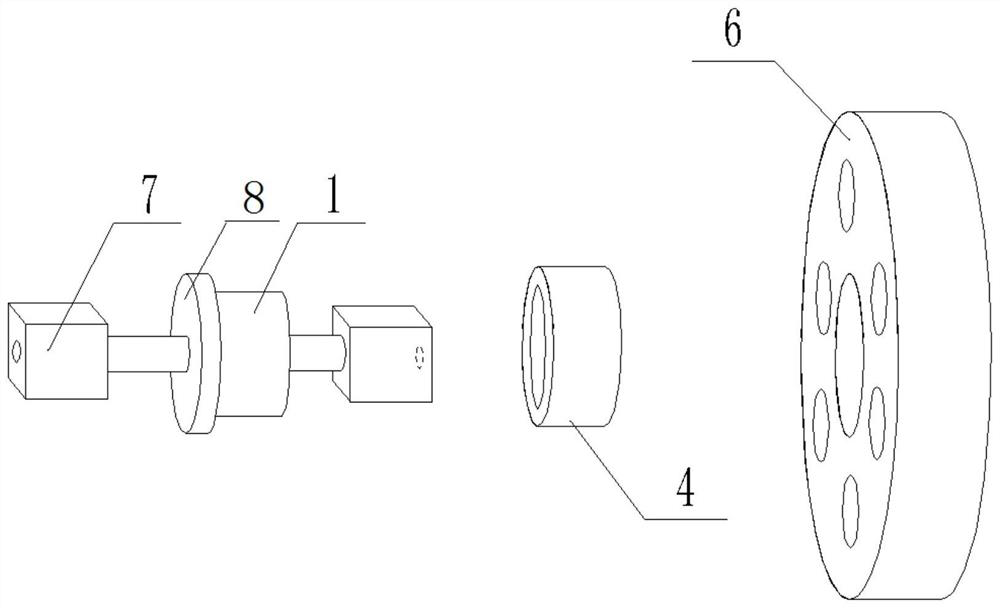

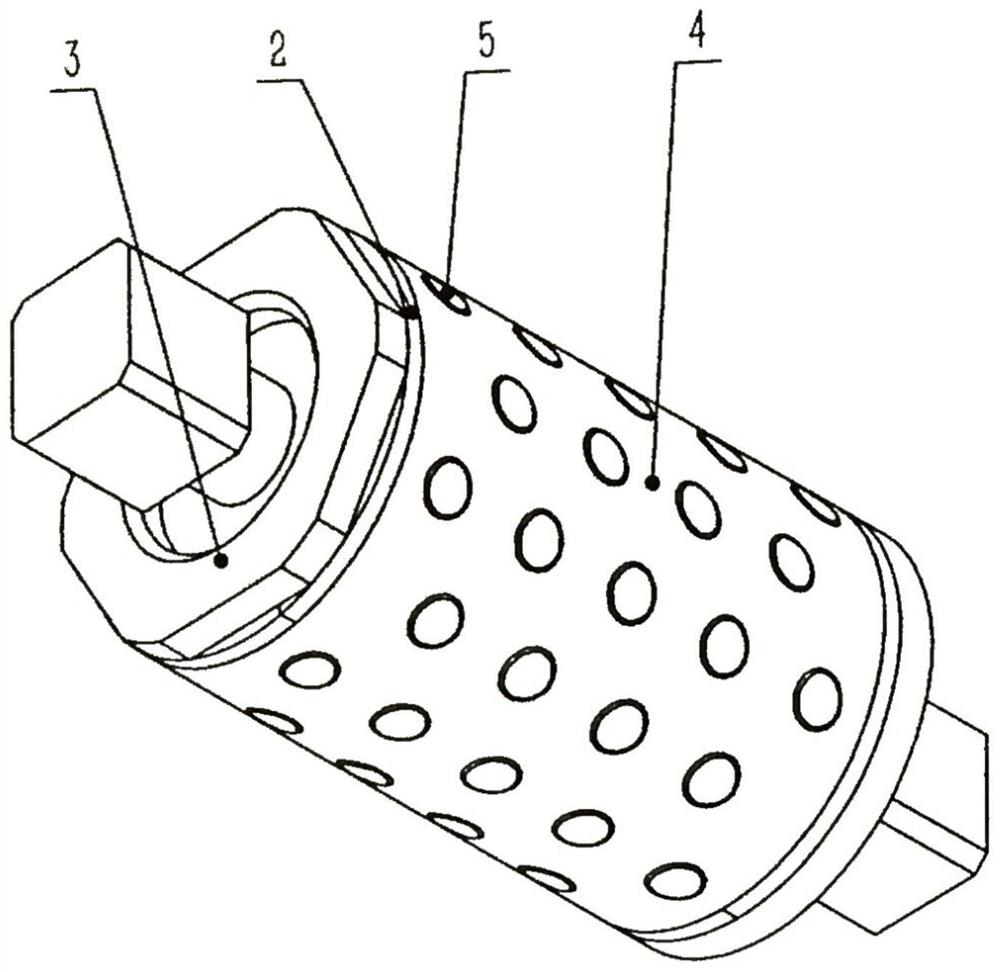

[0019] image 3 It is a structural schematic diagram of the integrated self-lubricating roller of the present invention, Figure 4 It is a schematic plan view of the integrated self-lubricating idler of the present invention. As shown in the figure, the integrated self-lubricating idler structure of the present invention for the roller type cooling bed of medium and thick plates includes a shaft 1 and a bushing 4. The shaft 1 Both ends are mounting heads 7, which are connected and installed on the cooling bed. The shaft 1 and the bushing 4 are integrally installed. One end of the shaft 1 is a protruding retaining ring 8, and the bushing 4 is set on the shaft 1 to be flush with the retaining ring 8. , the other end of the shaft 1 is machined with a section of external thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com