Simulation modeling method for simulating rock breaking process of laser-assisted tool

A laser-assisted, simulation modeling technology, applied in 3D modeling, design optimization/simulation, image data processing, etc., can solve the problems of lack of precision simulation modeling means for engineering applications, difficulty in simulating the whole process of laser-assisted tool breaking rocks, etc. , to achieve the effects of saving simulation analysis time, being easy to implement, and optimizing energy consumption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

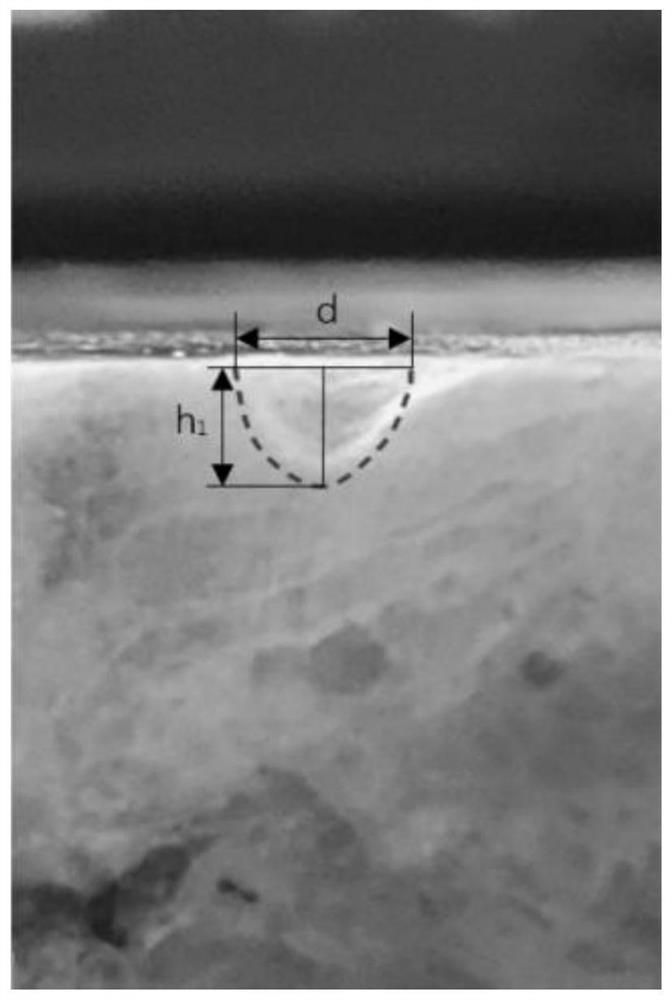

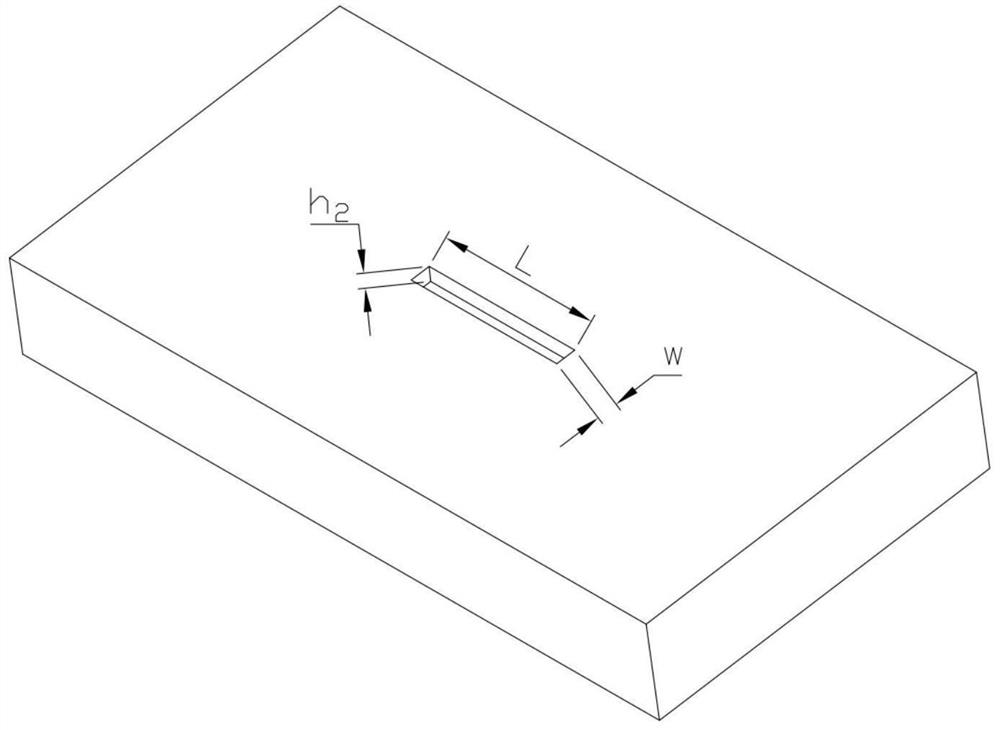

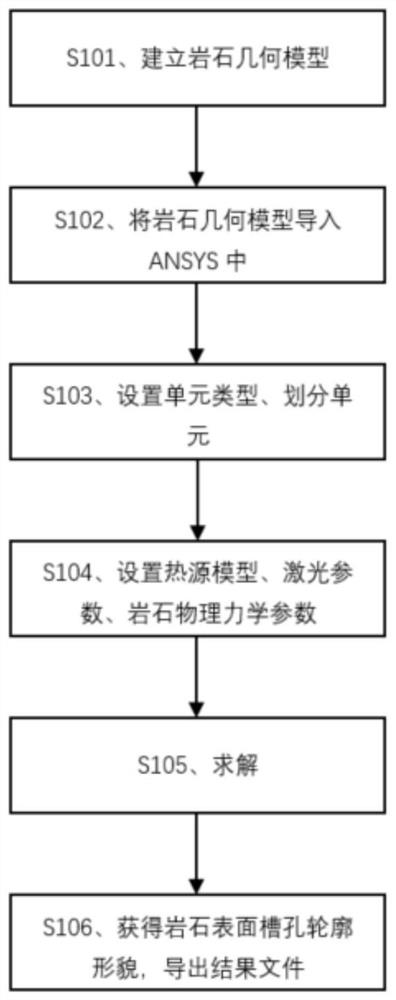

[0034] There are various forms and types of rock-breaking knives, among which hobs are the main rock-breaking knives for TBM. The rock breaking process of the hob includes various forms such as rock intrusion by the hob and rock breaking by the hob. In order to save space, the specific implementation process of a simulation modeling method for simulating the rock-breaking process of a laser-assisted cutter is introduced by taking the laser-assisted hob rock-breaking process as an example, which specifically includes the following steps:

[0035] S1: Use at least one method including but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com