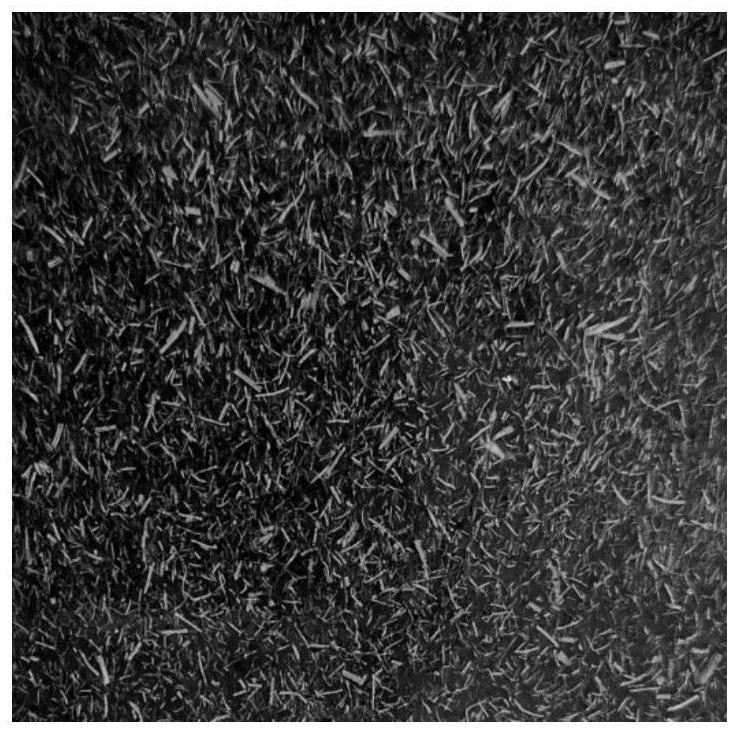

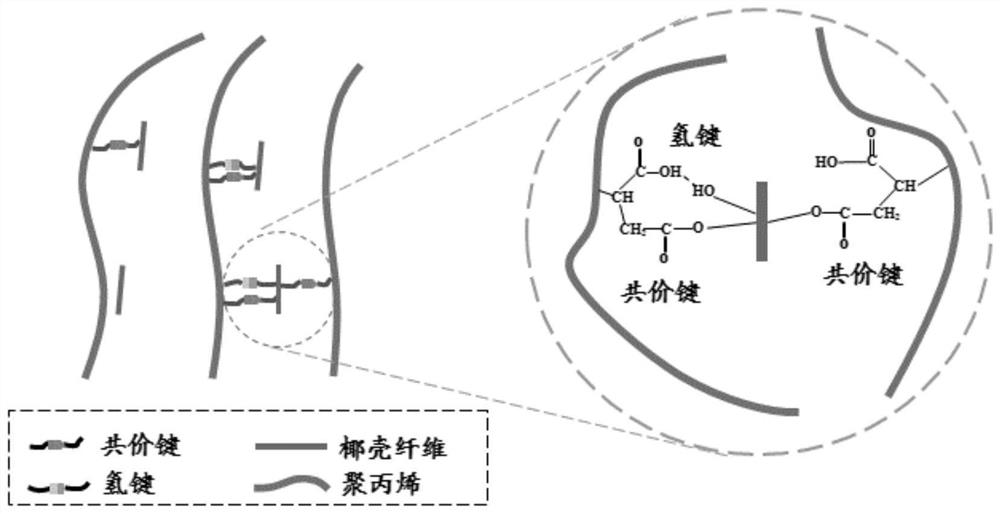

Filamentous-appearance high-performance flame-retardant coconut fiber modified polypropylene composite material as well as preparation method and application thereof

A composite material and coir fiber technology, which is applied in the field of plant fiber modified polypropylene composite materials, can solve the problems of long time for modification of jute fiber, no flame retardant effect, no special appearance, etc., so as to reduce material costs and improve Compatibility, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Prepare flame-retardant coconut shell fiber according to the following method: according to NaOH solution, AlCl 3 The mass ratio of solution and coconut shell fiber is 3:1:1, add coconut shell fiber in 10% NaOH solution, control the temperature at 80±1°C, add 2.0mol / L AlCl after stirring for 2h 3 solution, stirred for 2 hours, filtered and washed, and then dried at 100°C to obtain the flame-retardant coconut fiber.

[0047] 2) Weigh raw materials according to the following mass percentages: homopolypropylene: 5.23kg, block copolymerized polypropylene: 2kg, flame-retardant coconut shell fiber: 2kg, talcum powder: 0.5kg, compatibilizer: 0.2kg, antioxidant 1010: 0.03kg, antioxidant 168: 0.02kg, lubricant: 0.02kg.

[0048] 3) In addition to the flame-retardant coconut shell fiber, add other raw materials in step (2) into a high-speed mixer and mix for 3 minutes to make it evenly mixed.

[0049] 4) Add the material obtained in step (3) to the main feeding port of the tw...

Embodiment 2

[0053] 1) Prepare flame-retardant coconut shell fiber according to the following method: according to NaOH solution, AlCl 3 The mass ratio of solution and coconut shell fiber is 3:1:1, add coconut shell fiber in 10% NaOH solution, control the temperature at 80±1°C, add 2.0mol / L AlCl after stirring for 2h 3 solution, stirred for 2 hours, filtered and washed, and then dried at 100°C to obtain the flame-retardant coconut fiber.

[0054] 2) Weigh raw materials according to the following mass percentages: homopolypropylene: 4.13kg, block copolymerized polypropylene: 2kg, flame-retardant coconut shell fiber: 3kg, talcum powder: 0.5kg, compatibilizer: 0.3kg, antioxidant 1010: 0.03kg, antioxidant 168: 0.02kg, lubricant: 0.02kg.

[0055] 3) In addition to the flame-retardant coconut shell fiber, add other raw materials in step (2) into a high-speed mixer and mix for 3 minutes to make it evenly mixed.

[0056] 4) Add the material obtained in step (3) to the main feeding port of the tw...

Embodiment 3

[0060] 1) Prepare flame-retardant coconut shell fiber according to the following method: according to NaOH solution, AlCl 3 The mass ratio of solution and coconut shell fiber is 3:1:1, add coconut shell fiber in 10% NaOH solution, control the temperature at 80±1°C, add 2.0mol / L AlCl after stirring for 2h 3 solution, stirred for 2 hours, filtered and washed, and then dried at 100°C to obtain the flame-retardant coconut fiber.

[0061] 2) Weigh raw materials according to the following mass percentages: homopolypropylene: 3.03kg, block copolymerized polypropylene: 2kg, flame-retardant coconut shell fiber: 4kg, talcum powder: 0.5kg, compatibilizer: 0.4kg, antioxidant 1010: 0.03kg, antioxidant 168: 0.02kg, lubricant: 0.02kg.

[0062] 3) In addition to the flame-retardant coconut shell fiber, add other raw materials in step (2) into a high-speed mixer and mix for 3 minutes to make it evenly mixed.

[0063] 4) Add the material obtained in step (3) to the main feeding port of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com