System and method for controlling stable cooling after catalyst regeneration drying or roasting

A control system and catalyst technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unseen catalyst control, stable cooling, etc., to avoid catalyst cracking, simple principle, and measurement and control reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

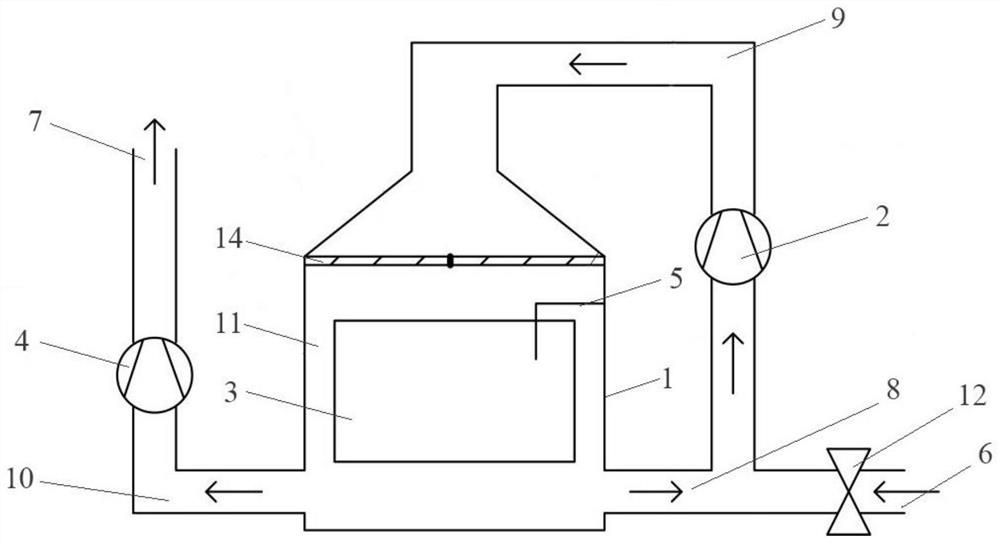

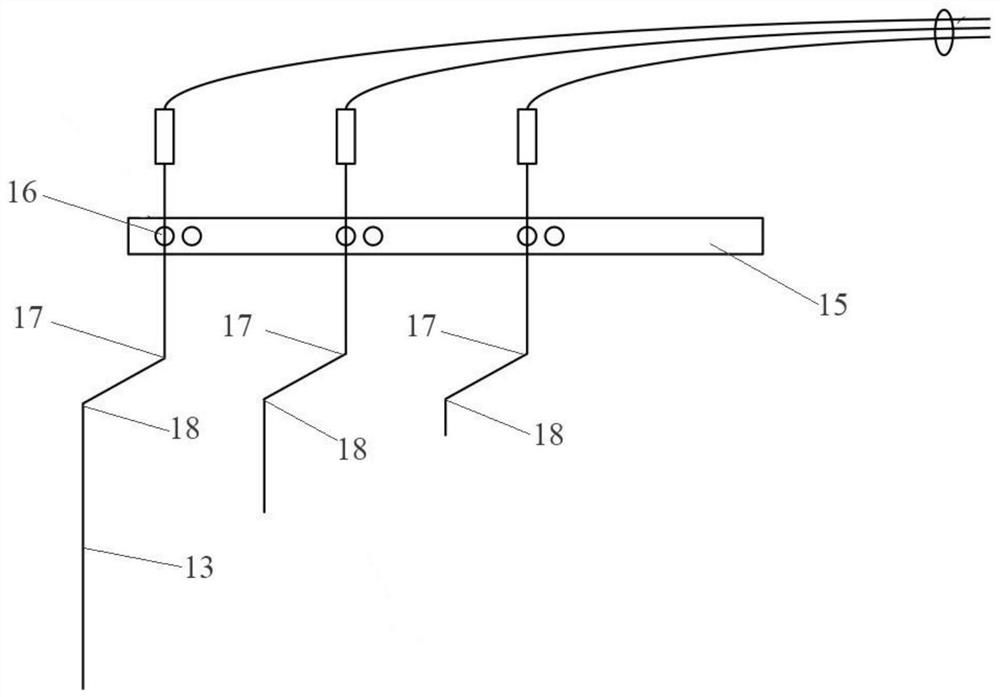

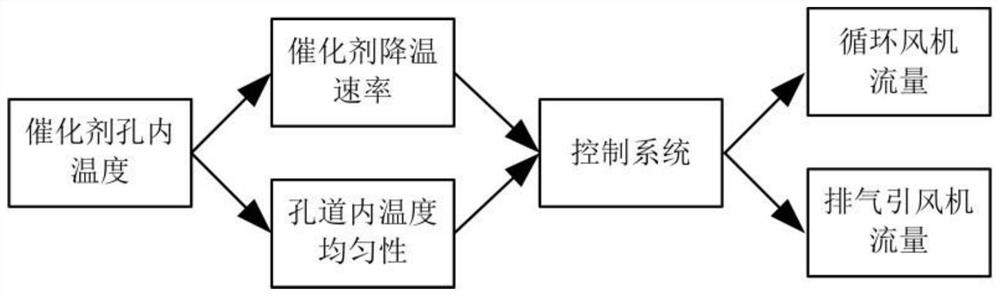

[0032] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a catalyst regeneration drying or roasting control and stable cooling system, which evenly blows the wind from the circulation fan 2 to the catalyst 3 through the top port of the cooling box 1 to drive the gas flow, so that the temperature is uniform, and is equipped with The exhaust fan 4 can control the amount of exhaust air, thereby controlling the rate of cooling, and is provided with a thermocouple assembly 5, and the thermocouple 13 is inserted into the hole of the catalyst 3 to measure the temperature in the hole, so that the control of the amount of exhaust air can be controlled. There is a basis, specifically, it includes a cooling device, a thermocouple assembly 5, a control system (not shown in the figure), the cooling device includes a cooling box 1, and the cooling box 1 includes an air inlet 6, an exhaust port 7, a first wind Road 8, the second air duct 9, the third air duct 10, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com