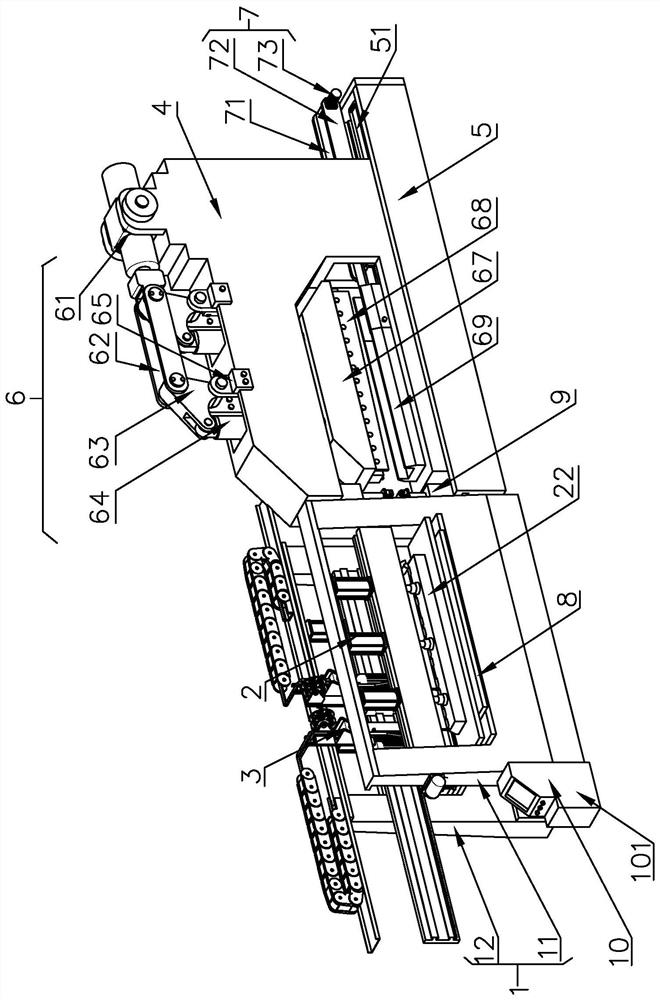

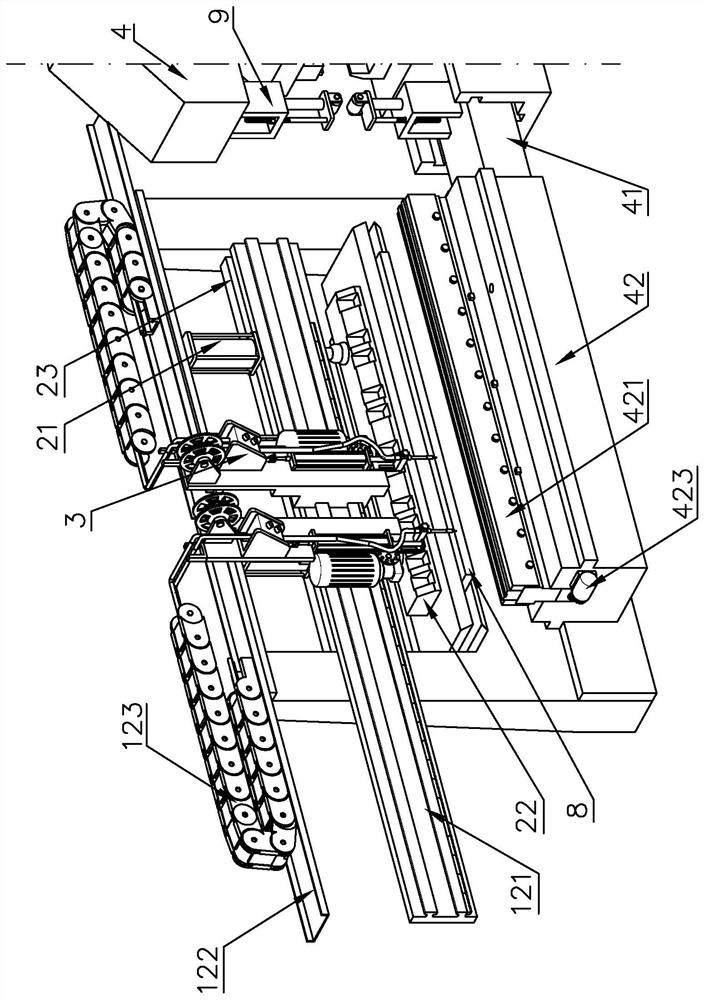

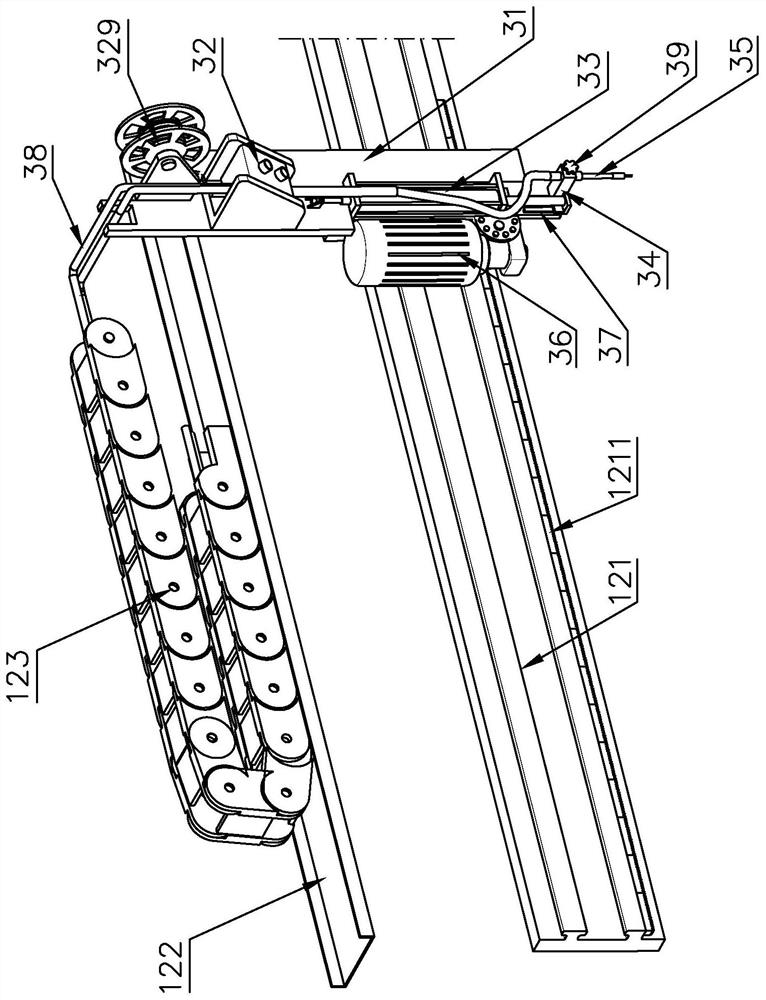

Pickling titanium plate welding device and welding process thereof

A welding device and titanium plate technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of wire feeder wire jamming, redundant welding wire, breakage, etc., and achieve the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A kind of pickling titanium plate welding process, its concrete steps are as follows:

[0067] 1) Steel belt transmission: The transmission mechanisms on both sides of the welding mechanism transport the two steel belts to be docked to the set position for cutting:

[0068] 2) Fixing: The two titanium plates are fixed and pressed firmly by the pressing mechanism to prepare for cutting;

[0069] 3) Cutting: Push the bracket through the third oil cylinder to enter between the front bracket and the rear bracket, and then cut the titanium plates that need to be welded butt by the cutting mechanism to make the butt joints flush;

[0070] 4) Alignment: Control the two titanium plates to butt the welding joints according to the requirements through the transmission mechanism on both sides of the frame so that the welding joints meet the welding requirements, and then press them firmly through the top pressure mechanism;

[0071] Among them, the welding gap of the 4mm thick ti...

Embodiment 2

[0080] Compared with Example 1, the difference is;

[0081] 4) Alignment: Control the two titanium plates to butt the welding joints according to the requirements through the transmission mechanism on both sides of the frame so that the welding joints meet the welding requirements, and then press them firmly through the top pressure mechanism;

[0082] Among them, the welding gap of the 4mm thick titanium plate on the operating side is set to 60% of the plate thickness; the welding gap on the opposite side of the operating side is set to 82% of the plate thickness;

[0083] The welding gap of the 7.5mm thick titanium plate on the operating side is set to 58% of the plate thickness; the welding gap on the opposite side of the operating side is set to 52% of the plate thickness;

[0084] 5) Welding: two steel plates are welded by an automatic welding machine;

[0085] The welding speed of a titanium plate with a thickness of 4mm is 0.8m / min; the current is 245A; the diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com