Power battery rapid separation system and method

A technology of quick detachment and power battery, which is applied in the direction of power devices, electric power devices, electric vehicles, etc., can solve the problems of small battery box, large volume, and the inability to quickly detach the power battery from the car body, and achieve sliding synchronization and sliding No jamming, fast installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

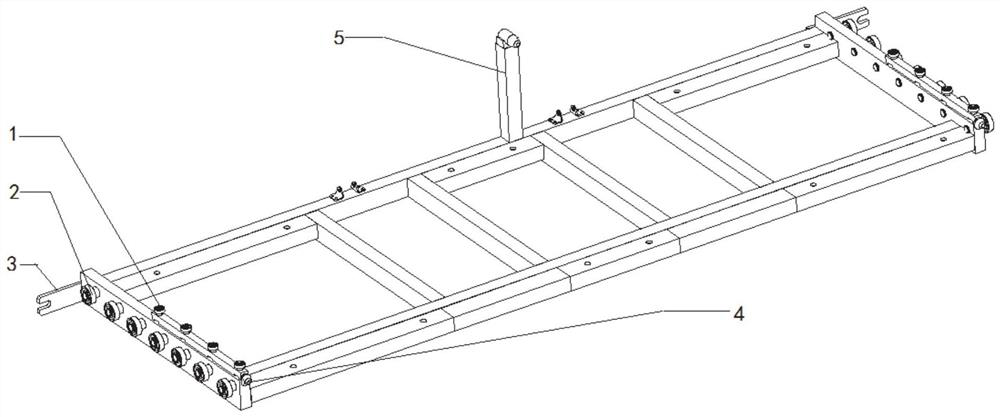

[0045] A preferred implementation case of the present disclosure is listed below, a power battery quick disengagement system, including a slidable bracket, a car body bracket fixed on the car body, and a quick locking device;

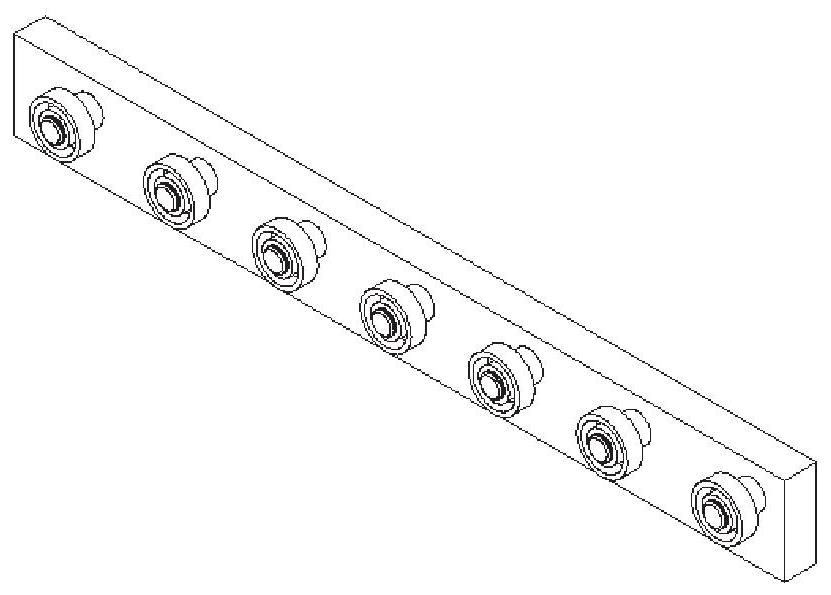

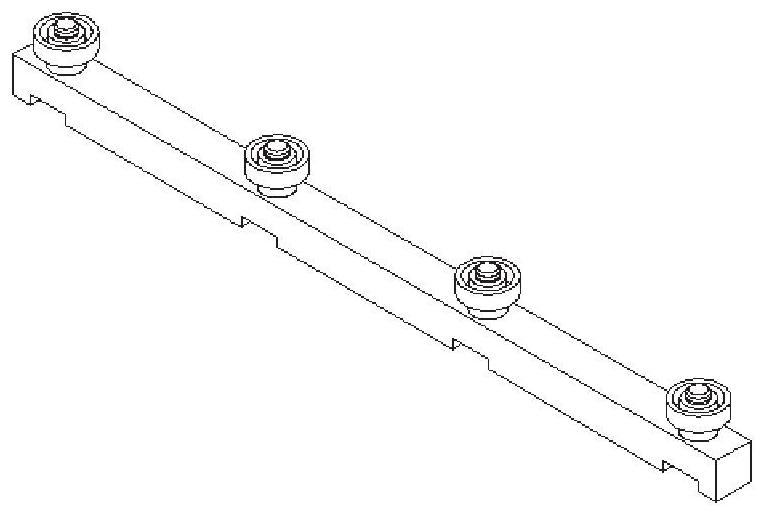

[0046] figure 1 The structure diagram of the slidable bracket described in this embodiment is shown in ; the slidable bracket includes a frame that uses bolts to fix the battery box. The internal components of the lower battery box meet its strength design requirements, and the sliding rollers and guide rollers installed on the frame, figure 2 The structural diagram of the sliding rollers in the slidable bracket described in this embodiment is shown in , image 3 The structural diagram of the guide rollers in the slidable bracket described in this embodiment is shown in ; the slidable rollers include two groups of several rollers, one set is arranged on the left and right side frames of the slidable cradle, and the rollers Arranged vertically on the ...

Embodiment 2

[0053] The purpose of this embodiment is to provide a method for quickly disconnecting a power battery.

[0054] A method for quickly disengaging a power battery, comprising:

[0055] The slidable bracket slides into the vehicle body bracket along the roller slideway, the taper pin fits seamlessly with the positioning sleeve, and the outermost frame of the slidable bracket and the vehicle body bracket are quickly locked The device is fixed and locked by a spring locking pin, and the slidable bracket is in a locked state;

[0056] When a crisis situation occurs, perform the step of quickly disengaging the battery, including pulling out the spring locking pin, loosening the fixing nut, and turning the bolt out of the positioning plate of the slidable bracket, and the slidable bracket is in a movable state;

[0057] The slidable bracket is pulled out of the vehicle body support through the traction rope, so as to realize the quick detachment of the battery.

[0058] Correspondi...

Embodiment 3

[0065] The purpose of this embodiment is to provide an electric vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com