Long-afterglow luminous geopolymer concrete

A long afterglow luminescence and geopolymer technology, applied in cement production and other directions, can solve the problems of weakening mechanical properties, luminous materials, construction difficulties, etc., and achieve the effect of prolonging afterglow time, limiting volume shrinkage, and reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

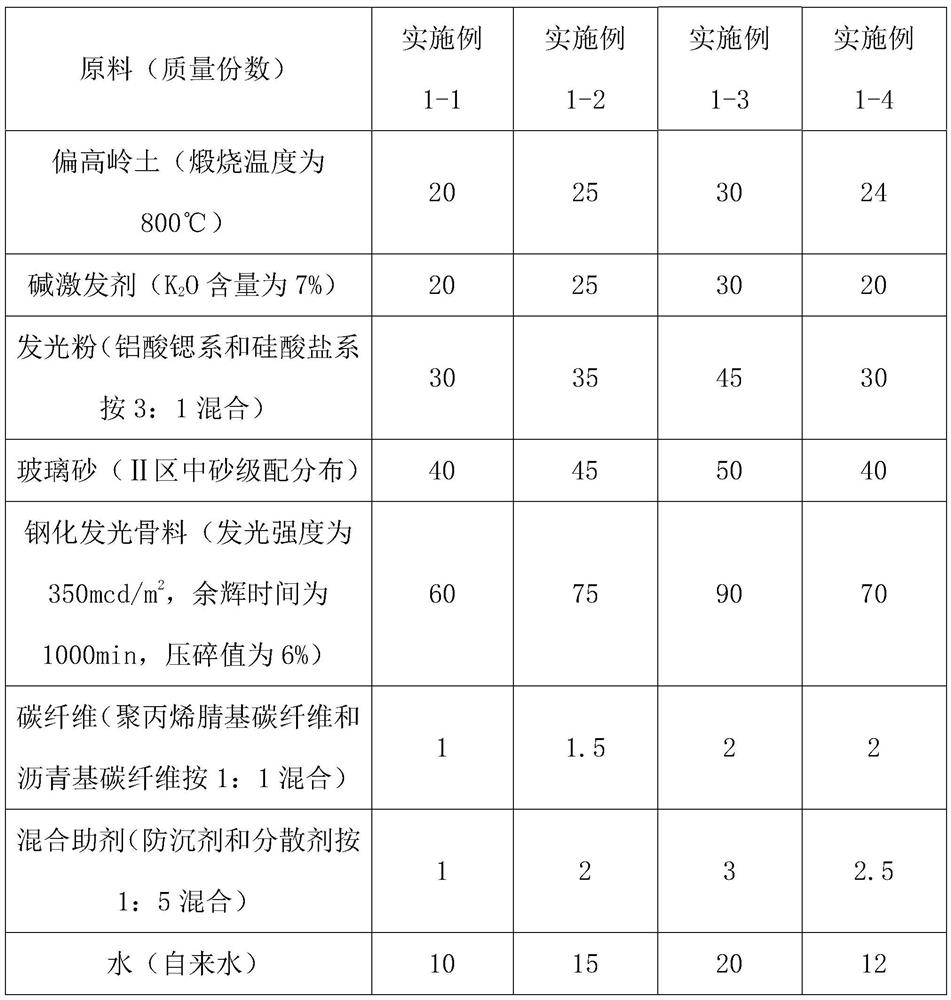

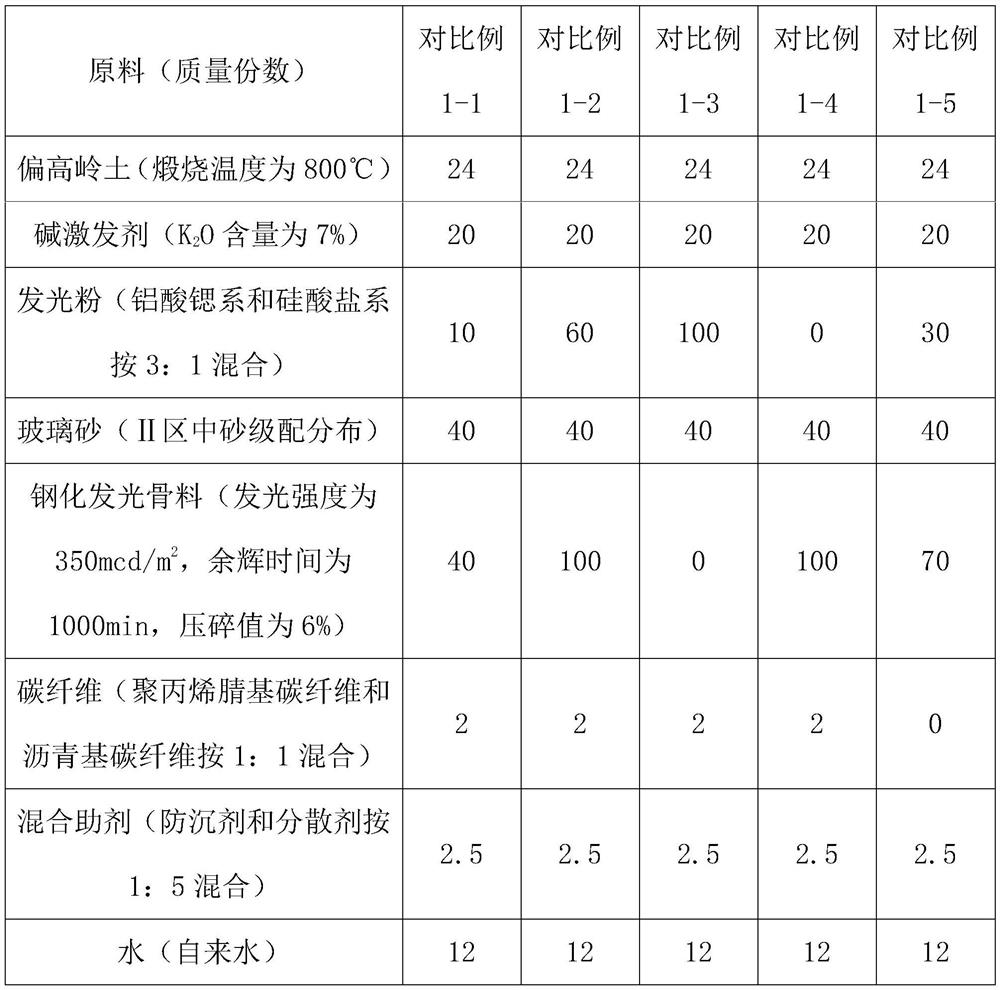

Examples

Embodiment 2-1

[0079] The luminous intensity of luminescent aggregate is 400mcd / m 2 , the afterglow time is 1100min, and the crushing value is 5%;

Embodiment 2-2

[0081] The luminous intensity of luminescent aggregate is 200mcd / m 2 , the afterglow time is 600min, and the crushing value is 6%;

Embodiment 2-3

[0083] The luminous intensity of luminescent aggregate is 350mcd / m 2 , the afterglow time is 1000min, and the crushing value is 18%;

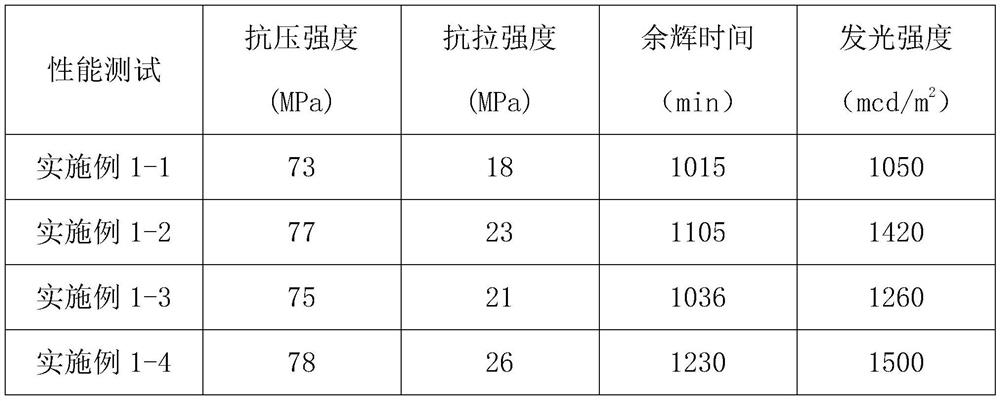

[0084] Prepare luminous geopolymer concrete according to the above method, and carry out compressive strength test, tensile strength test, luminous intensity test and afterglow time test on the obtained luminous geopolymer concrete, and the results are shown in the following table:

[0085] Table 5 Performance test results of different luminescent geopolymer concretes in Example Group 2

[0086]

[0087]

[0088] From the performance test results of Example Group 2, it can be seen that the luminous intensity ≥ 350mcd / m used in this technical solution 2 The luminous aggregate with afterglow time ≥ 1000min is conducive to fully improving the luminous effect of luminous geopolymer concrete; further, this technical solution uses luminous aggregate that has been tempered, and its crushing value can reach ≤ 6%. Compared with the use of untemp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com