Piezoelectric ceramic and preparation method thereof

A technology of piezoelectric ceramics and internal stress, which is applied in the field of functional materials, can solve problems such as complexity or dangerous practical discounts, and achieve the effects of improving piezoelectric thermal stability, simple preparation process, and reducing applied pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a method for preparing piezoelectric ceramics described in the above technical solution, comprising:

[0039] Mixing the raw materials for preparing the piezoelectric ceramics to obtain a mixed powder;

[0040] After mixing the mixed powder and the binder, pressing to obtain a green body;

[0041] Sintering the green body to obtain piezoelectric ceramics;

[0042] The weight of the mixed powder is 0.2~1g;

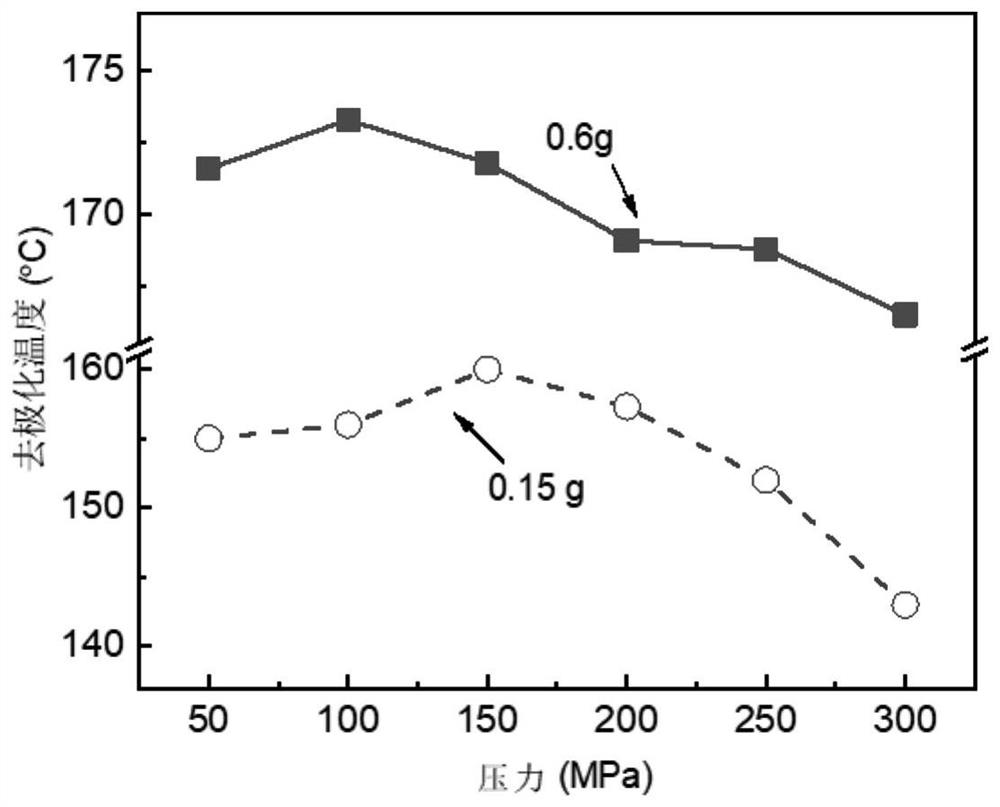

[0043] The pressing pressure is 50~300MPa;

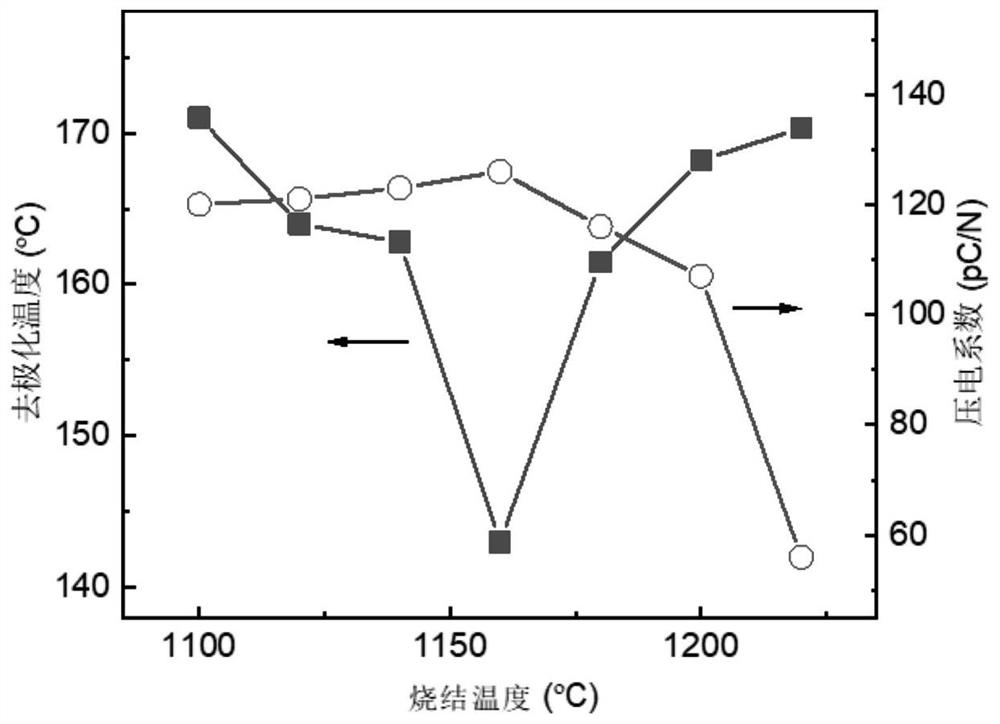

[0044] The sintering temperature is 1100-1250°C.

[0045] In the present invention, the method for preparing piezoelectric ceramics is to increase the weight of raw materials on the basis of the original preparation of piezoelectric ceramics, reduce the pressure of compression molding, and reduce the sintering temperature; the weight increase of the raw materials for preparation is preferably 0.5 ~ 1.5g, more preferably 0.8 ~ 1.2g, most preferably 1.0g; the pressure reduction of the press...

Embodiment 1

[0068] Example 1 (Na 0.5 Bi 0.5 ) 0.92 Ba 0.08 Ti 0.99 Mg 0.01 o 3 : NBT8M1.0 ferroelectric ceramic

[0069] NBT8M1.0 ceramic samples were prepared by traditional solid-phase synthesis method, and a certain proportion of Bi was stoichiometrically 2 o 3 , Na 2 CO 3 , BaCO 3 , MgO, TiO 2 (Analytical grade, Sinopharm Group) mixed, added alcohol ball mill for 12 hours, dried, and kept at 850°C for 2 hours to synthesize the initial powder whose component is NBT8 M1.0. Then add alcohol to the synthesized powder and ball mill it again for 12 hours and then dry it, add 10% binder (5% mass concentration of polyvinyl alcohol (PVA) aqueous solution) of the powder weight, and select a mold with a diameter of 0.5 inches to pass through a single shaft The compression method is pressed into a green body.

[0070] The weight of the initial powder is 0.2g, and the pressure of uniaxial compression is 200MPa;

[0071] After burning off the binder in the green body at a high tempera...

Embodiment 2~5

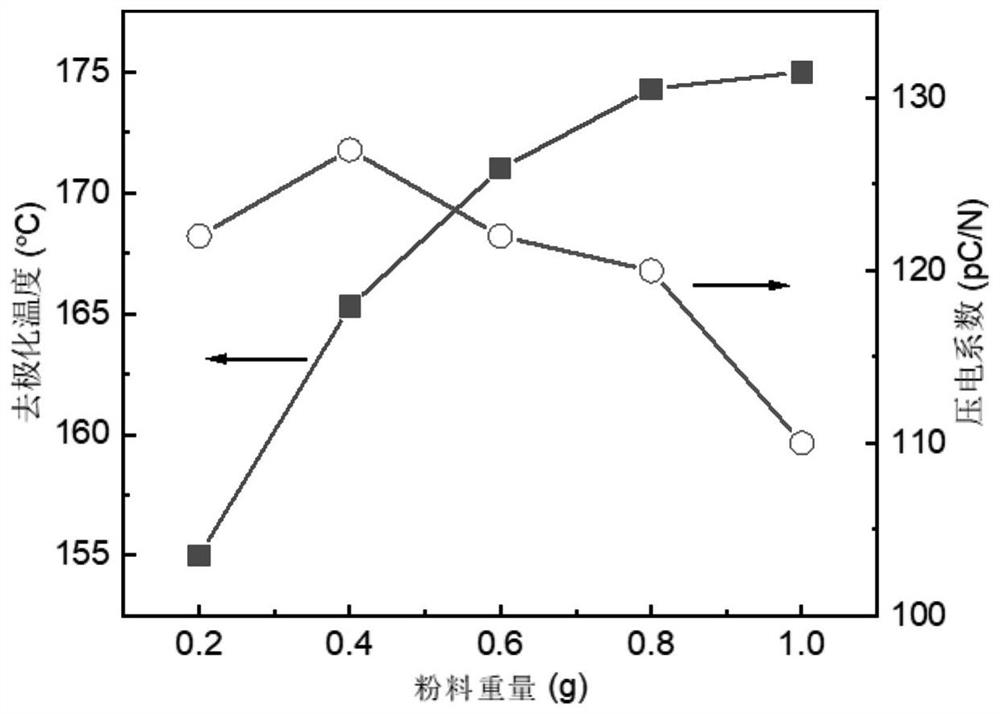

[0076] Ferroelectric ceramics were prepared according to the method of Example 1, the difference from Example 1 was that the weight of the initial powder was replaced by 0.4g, 0.6g, 0.8g, and 1.0g, respectively.

[0077] According to the method of Example 1, the properties of the ferroelectric ceramics prepared in Examples 2 to 5 are detected, and the detection results are as follows figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com