Vacuum magnetic control mobile phone rear shell coating process

A mobile phone back shell and mobile phone shell technology, which is applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problem of reducing the quality of the magnetron sputtering coating on the back shell of the mobile phone and unfavorable use of the coating on the back shell of the mobile phone , Affect the coating effect of the back shell of the mobile phone, etc., to achieve the effect of improving the coating effect, eliminating stress, and improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

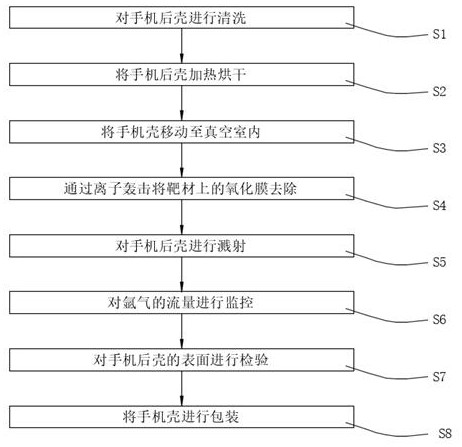

[0028] see figure 1 , the present invention provides a technical solution: a coating process for the back shell of a vacuum magnetron mobile phone, comprising the following steps:

[0029] S1. Clean the back shell of the mobile phone;

[0030] S2, heating and drying the back shell of the mobile phone;

[0031] S3, move the back shell of the mobile phone into the vacuum chamber;

[0032] S4, removing the oxide film on the target by ion bombardment;

[0033] S5. Carry out sputter coating on the back shell of the mobile phone;

[0034] S6, monitoring the flow of argon;

[0035] S7, inspecting the surface of the mobile phone rear shell;

[0036] S8, packing the mobile phone case.

[0037] In this embodiment, specifically: in S1, put the back shell of the mobile phone into the cleaning equipment, and clean the dirt and impurities on the surface of the back shell of the mobile phone. The cleaning time is 10 minutes, and the temperature of the cleaning water is 50°C; The rear ...

Embodiment 2

[0046] see figure 1 , the present invention provides a technical solution: a coating process for the back shell of a vacuum magnetron mobile phone, comprising the following steps:

[0047] S1. Clean the back shell of the mobile phone;

[0048] S2, heating and drying the back shell of the mobile phone;

[0049] S3, move the back shell of the mobile phone into the vacuum chamber;

[0050] S4, removing the oxide film on the target by ion bombardment;

[0051] S5. Carry out sputter coating on the back shell of the mobile phone;

[0052] S6, monitoring the flow of argon;

[0053] S7, inspecting the surface of the mobile phone rear shell;

[0054] S8, packing the mobile phone case.

[0055]In this embodiment, specifically: in S1, put the back shell of the mobile phone into the cleaning equipment, and clean the dirt and impurities on the surface of the back shell of the mobile phone. The cleaning time is 15 minutes, and the temperature of the cleaning water is 55°C; The rear c...

Embodiment 3

[0064] see figure 1 , the present invention provides a technical solution: a coating process for the back shell of a vacuum magnetron mobile phone, comprising the following steps:

[0065] S1. Clean the back shell of the mobile phone;

[0066] S2, heating and drying the back shell of the mobile phone;

[0067] S3, move the back shell of the mobile phone into the vacuum chamber;

[0068] S4, removing the oxide film on the target by ion bombardment;

[0069] S5. Carry out sputter coating on the back shell of the mobile phone;

[0070] S6, monitoring the flow of argon;

[0071] S7, inspecting the surface of the mobile phone rear shell;

[0072] S8, packing the mobile phone case.

[0073] In this embodiment, specifically: in S1, put the back case of the mobile phone into the cleaning equipment, and clean the dirt and impurities on the surface of the back case of the mobile phone. The cleaning time is 20 minutes, and the temperature of the cleaning water is 60°C; The rear ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com