Method for producing L-threonine

A threonine and production rate technology, applied in the field of L-threonine production, can solve problems such as poor operability, lack of feeding basis for control methods, and inability to achieve precise and optimal control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

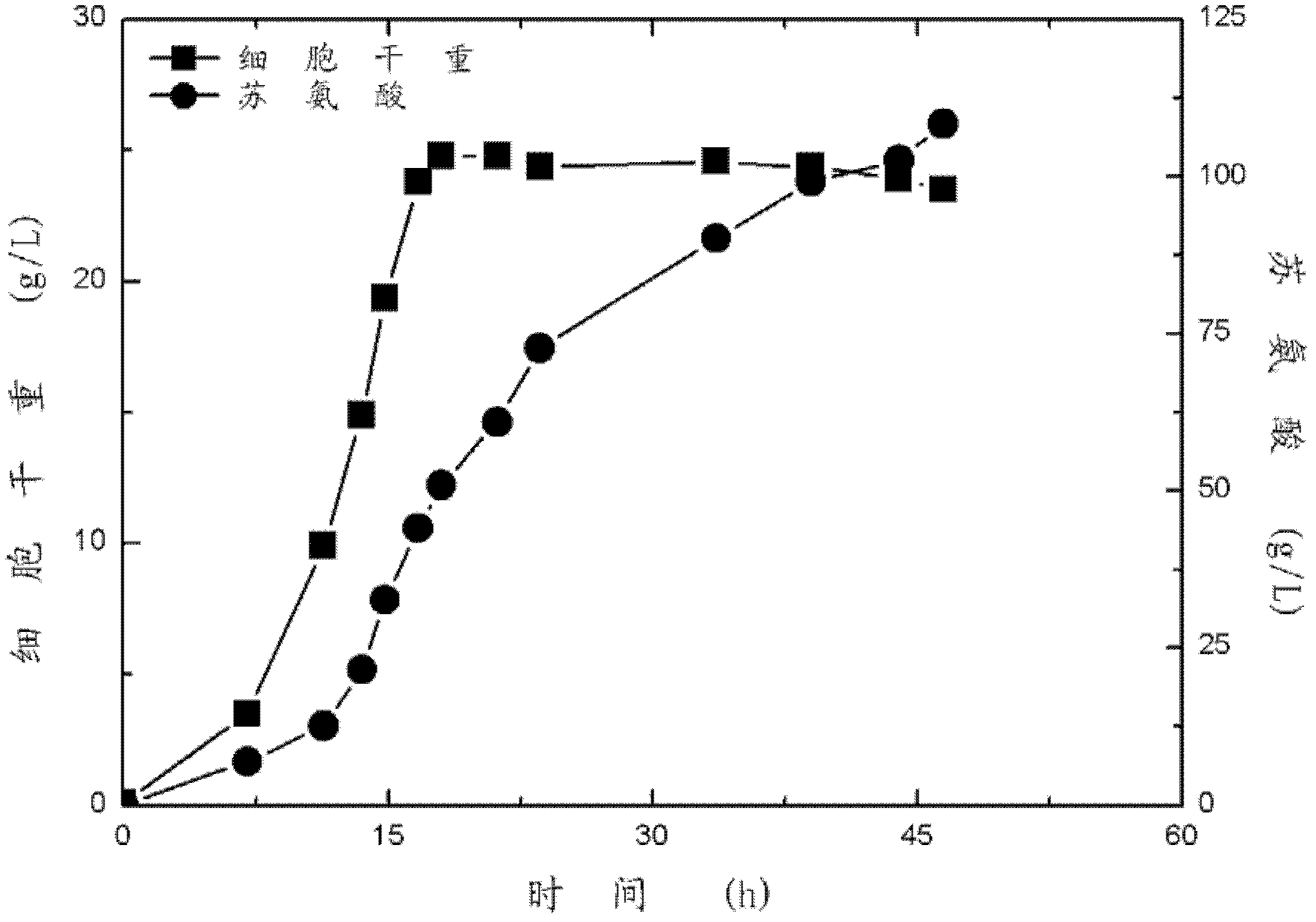

[0062] Embodiment 1, production of L-threonine by fermentation (isoleucine feed)

[0063] 1. Experimental materials

[0064] The used seed culture medium of the present embodiment is made up of water and solute; The concentration of described solute in culture medium is as follows: glucose 40g / L, ammonium sulfate 15g / L, potassium dihydrogen phosphate 2g / L, magnesium sulfate 2g / L, Yeast powder 2g / L, L-isoleucine 0.05g / L, calcium carbonate 15g / L, trace element mixture 2mL / L.

[0065] The initial fermentation medium used in this embodiment is composed of water and solute; the concentration of the solute in the medium is as follows: glucose 10g / L, ammonium sulfate 10g / L, potassium dihydrogen phosphate 2g / L, magnesium sulfate 2g / L , yeast powder 2g / L, trace element mixture 2mL / L.

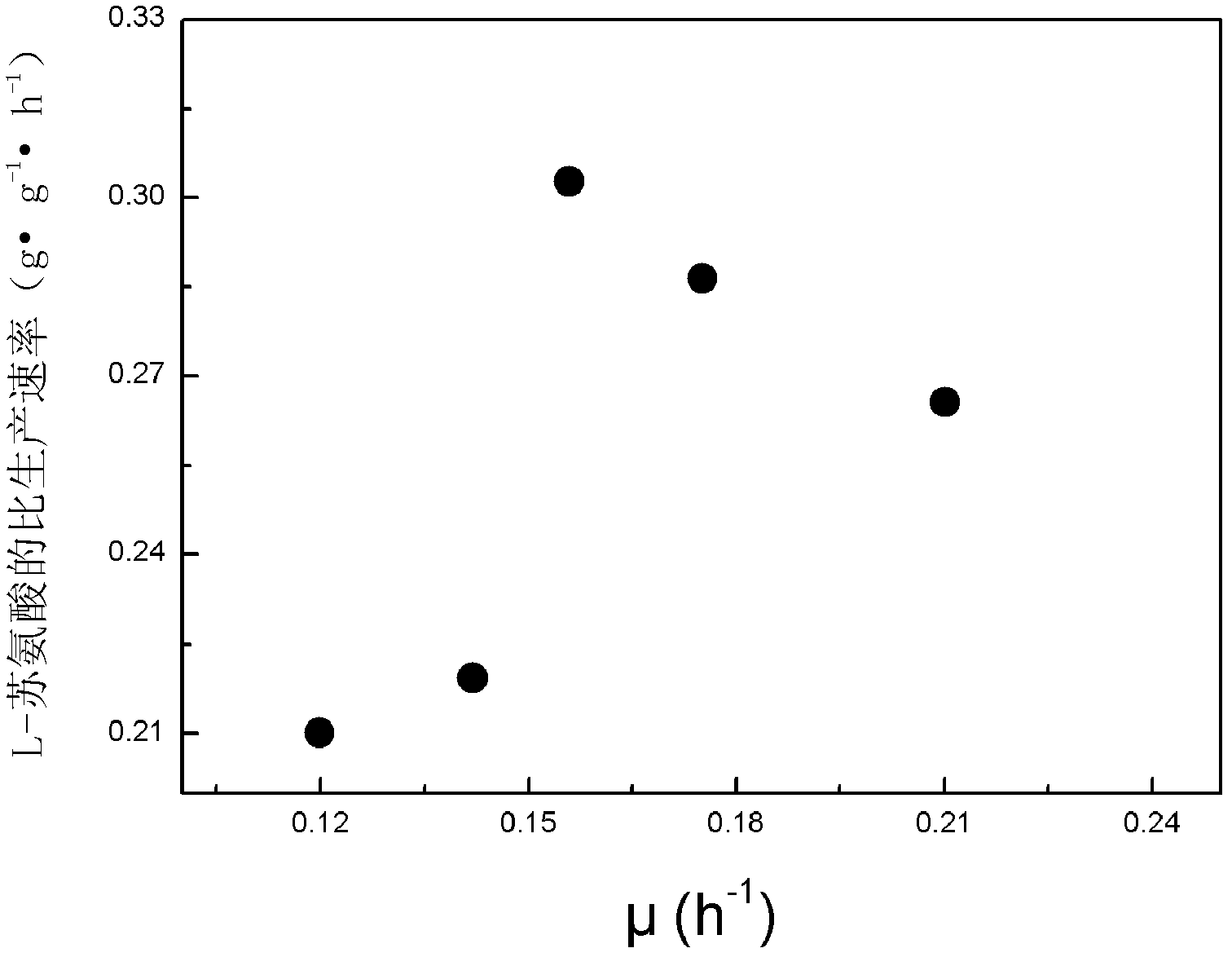

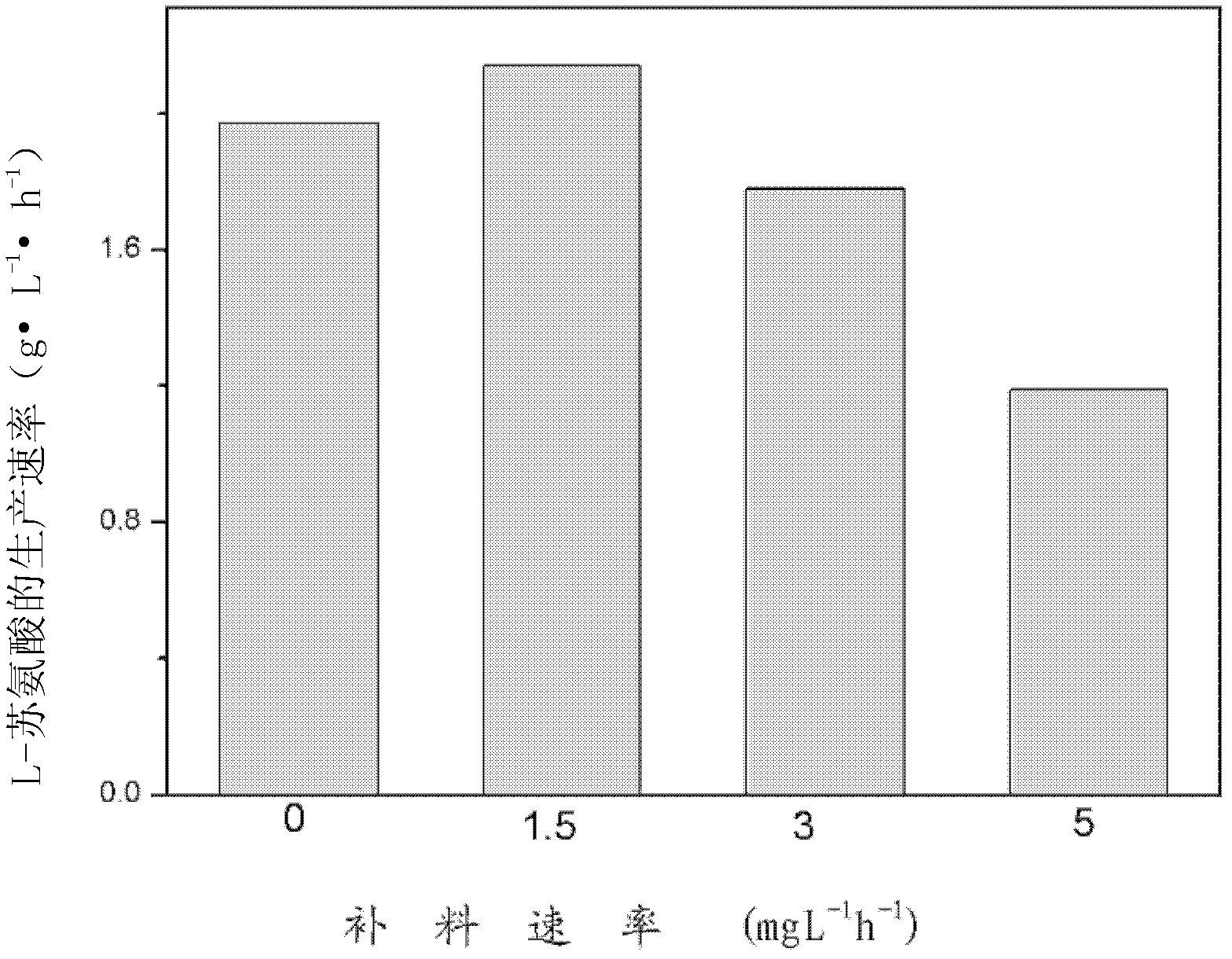

[0066] It is determined by preliminary experiments that the cell yield of Escherichia coli EC125 using L-isoleucine as a substrate is 107g / g (that is, every gram of L-isoleucine produces 107 grams of dry...

Embodiment 2

[0101] Embodiment 2, production of L-threonine by fermentation (potassium dihydrogen phosphate and isoleucine mixed feed)

[0102] 1. Experimental materials

[0103] The used seed culture medium of the present embodiment is made up of water and solute; The concentration of described solute in culture medium is as follows: glucose 40g / L, ammonium sulfate 15g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate 2g / L, Yeast powder 2g / L, L-isoleucine 0.05g / L, calcium carbonate 15g / L, trace element mixture 2mL / L.

[0104] The initial fermentation medium used in this embodiment is composed of water and solute; the concentration of the solute in the medium is as follows: glucose 10g / L, ammonium sulfate 10g / L, magnesium sulfate 2g / L, yeast powder 2g / L, trace Element mixture 2mL / L.

[0105] 2. Production of L-threonine by fermentation

[0106] 1. Same as step 2 of embodiment 1.

[0107]2. Inoculate the initial fermentation medium in the fermenter with the seed liquid of step 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com