Arrangement process for recovering remaining coal pillars and treating ground gangue in room type coal mining method

A technology of legacy coal pillars and room-type coal pillars, which is applied in ground mining, mining equipment, earth-moving drilling, etc., can solve the problems of safe mining of coal seams under influence, prolonging the service life of resource-depleted mines, and waste of resources, etc., and achieve comprehensive benefits. Significant, reduced accumulation emissions, lower tax effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

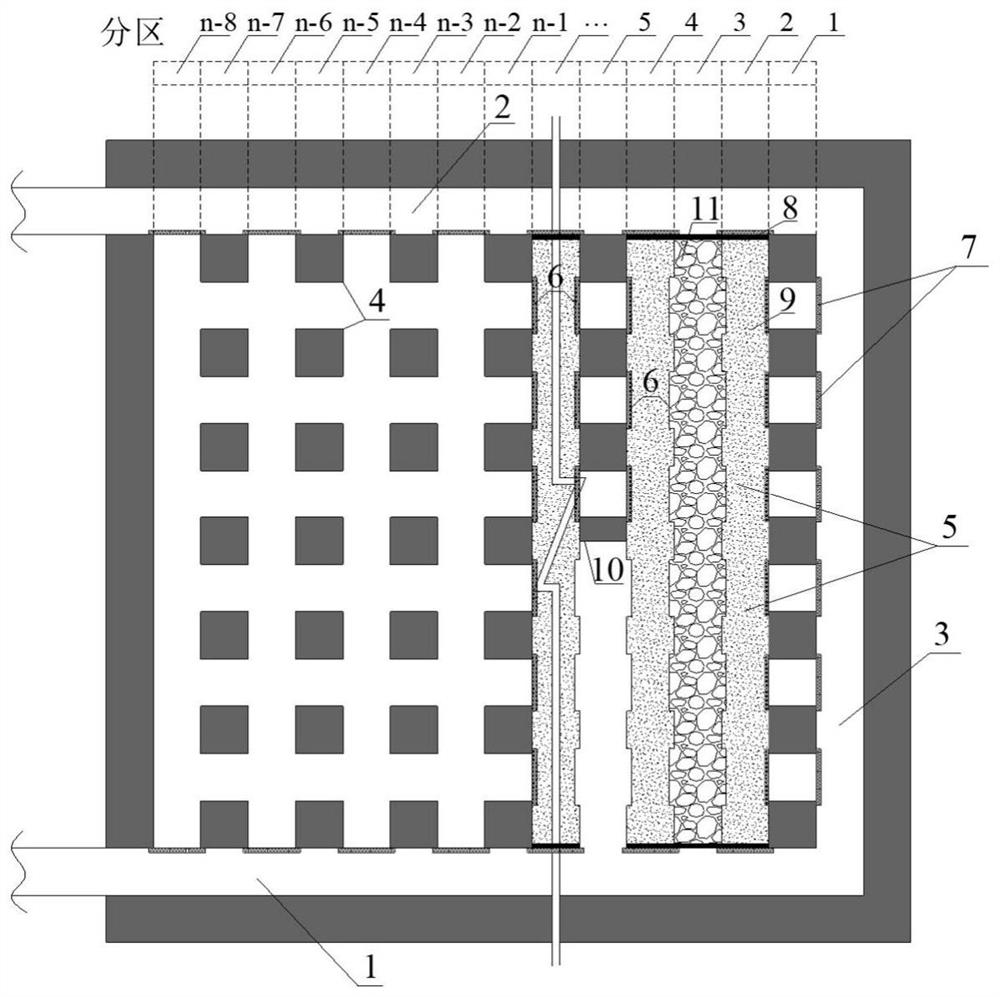

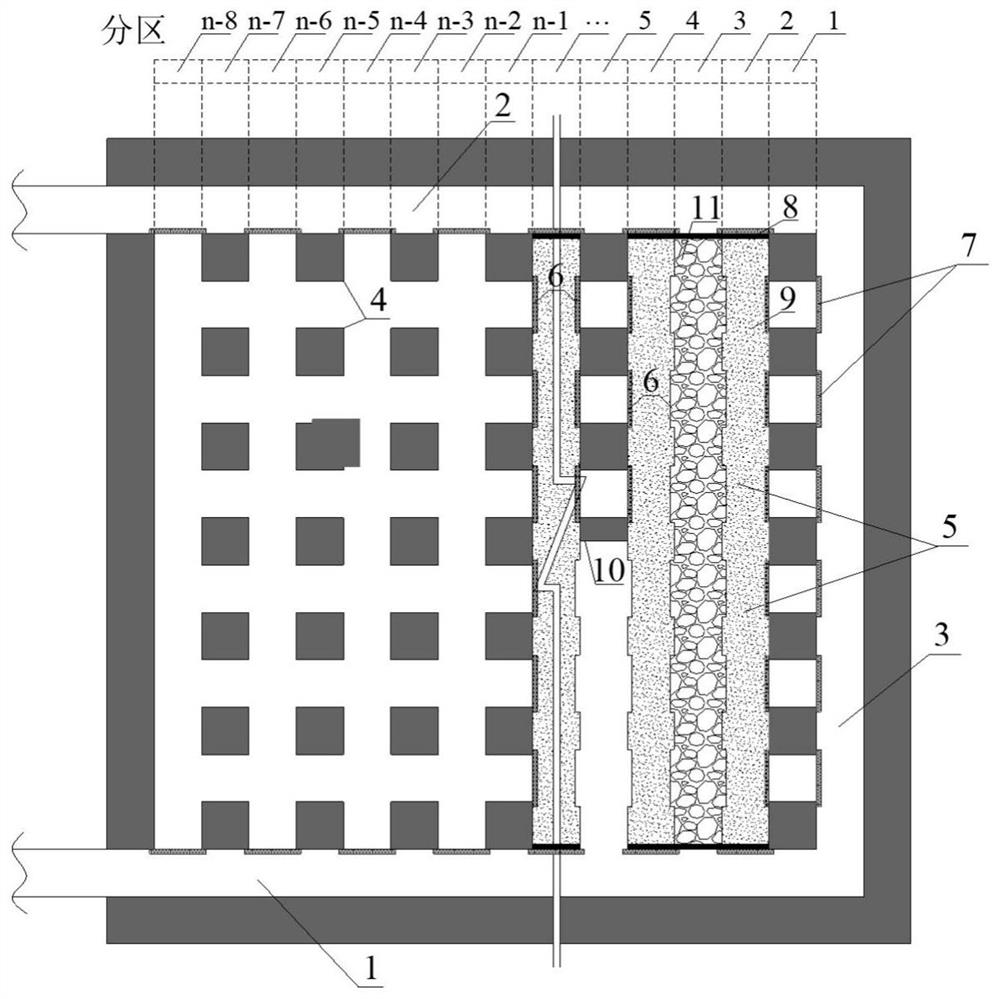

[0025] The specific implementation process of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] The present invention provides a method for laying out coal pillars left over from mining chamber-type coal mining methods and processing ground gangue, comprising the following steps:

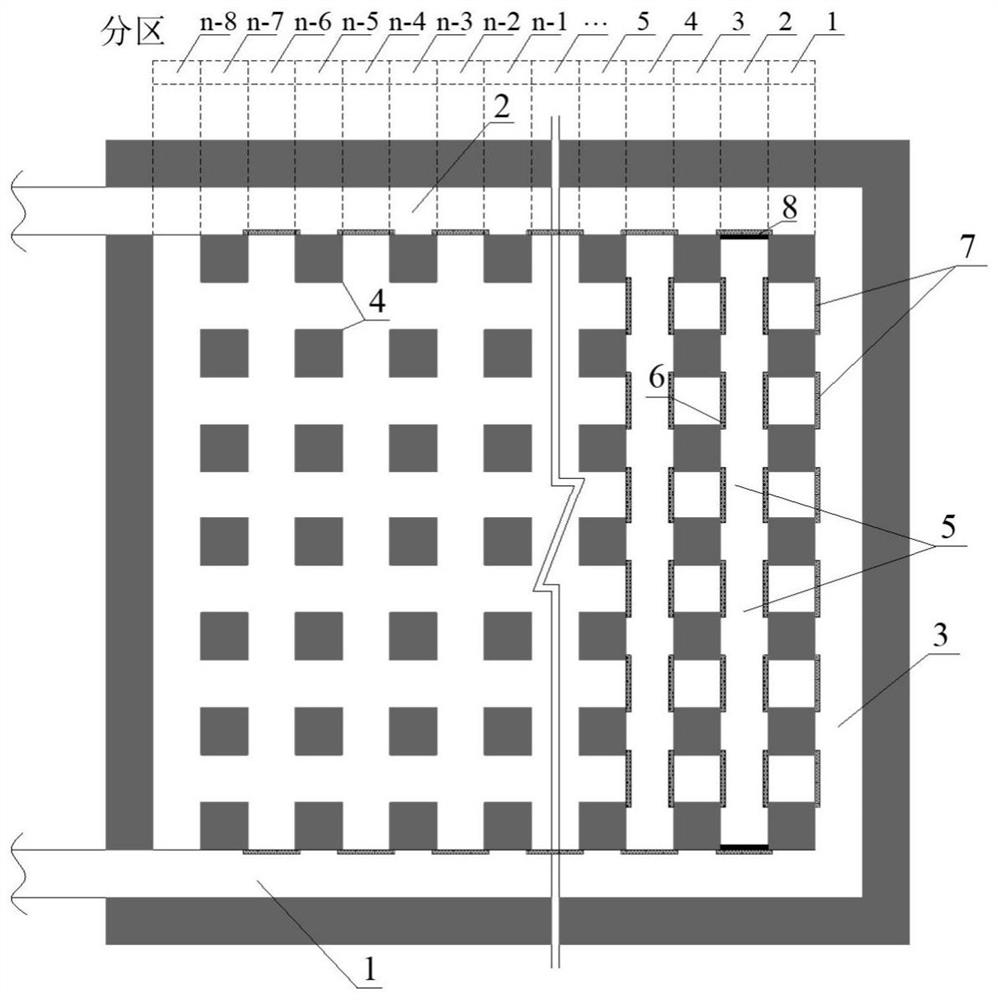

[0027] a. The layout of the coal pillar and coal room before the mining of room type coal pillar 4 is as follows figure 1 shown. Firstly, a windshield curtain 7 is hung between two adjacent coal pillars on the outside of the goaf to form a complete air intake and return system. At the same time, the air inlet and transport alley 1 is also used as the room-type coal pillar recovery period. The transportation alley, the return air alley and the auxiliary transportation alley 2 are also used as the auxiliary transportation alley during the room type coal pillar recovery, and the boundary air guide alley 3 is used to connect the air inlet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com