Solar multi-energy complementation system for heating and operation method

A technology of solar energy and solar heat collector, which is applied in the solar multi-energy complementary system and the field of operation, can solve the problems of low heat absorption efficiency of refrigerant pipes, poor economic performance, and low heat exchange of the entire component, so as to improve operating efficiency and reduce Operating costs, the effect of reducing loss and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

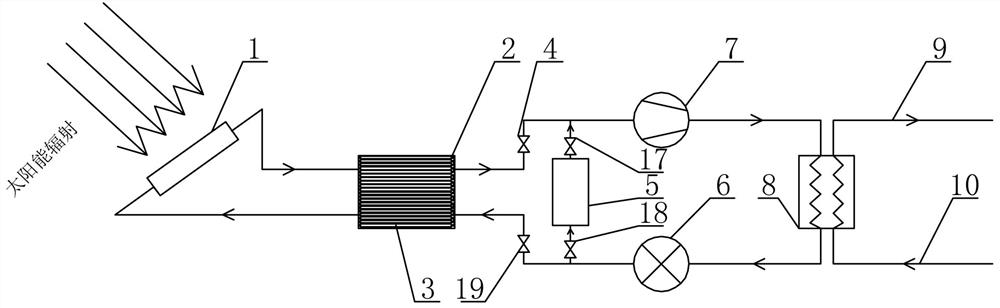

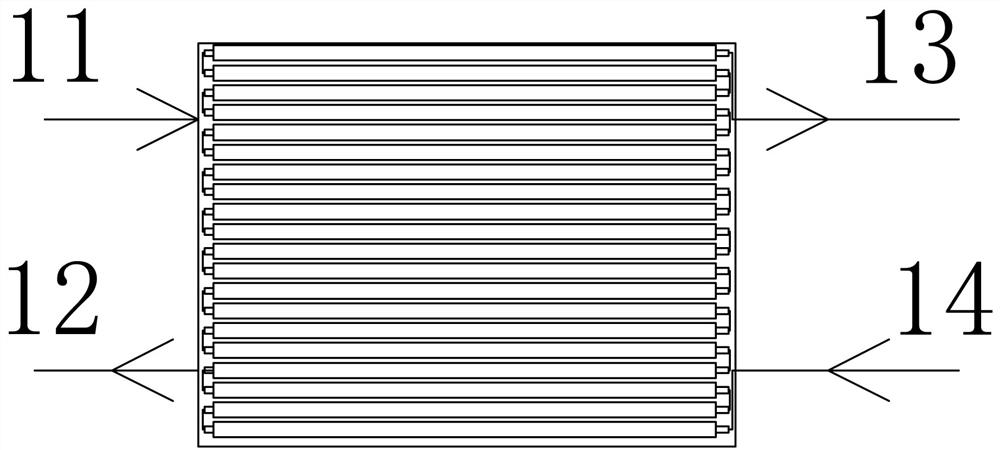

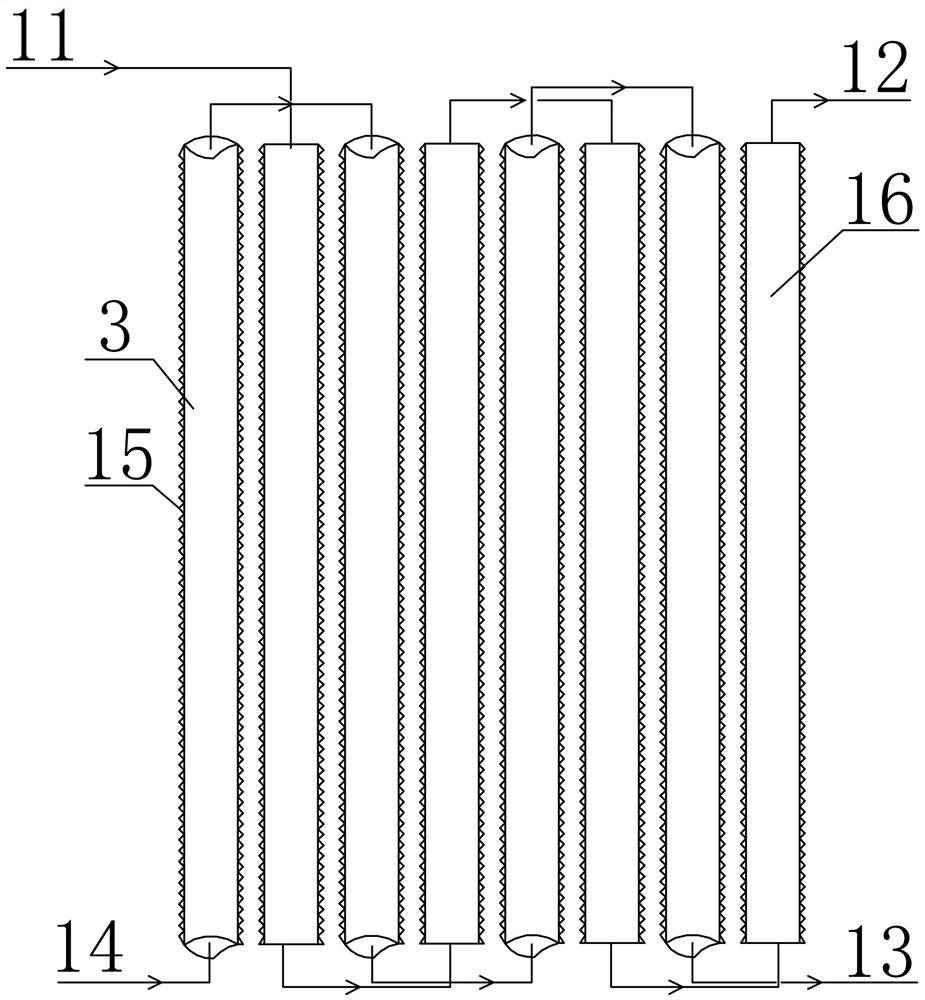

[0033] Such as Figure 1-3 As shown, a solar multi-energy complementary system for heating, it includes a solar heat collector 1, the outlet of the solar heat collector 1 is connected in series with a tube-fin evaporator 2, a first shut-off valve 4 and connected with the evaporator 5 in parallel, and then in series with the compressor 7, condenser 8 and throttle valve 6; after the throttle valve 6, there are two channels connected in parallel, one of which is connected to the inlet of the evaporator 5 through the second stop valve 18, and the other channel The third cut-off valve 19 is connected to the inlet of the tube-fin evaporator 2, and the tube-fin evaporator 2 is connected to the inlet of the solar collector 1; the outlet of the evaporator 5 is connected to the compressor 7 through the fourth cut-off valve 17. The inlets are connected; the condenser 8 is connected with a hot water outlet channel 9 and a cold water inlet channel 10 . By adopting the above system, this s...

Embodiment 2

[0045] Operation method of solar multi-energy complementary system for heating:

[0046] The method of normal operation of the solar collector during the day:

[0047] When the weather is fine during the day, when the solar collector 1 can operate normally, the fourth shut-off valve 17 and the second shut-off valve 18 of the main road are in a closed state, and the first shut-off valve 4 and the third shut-off valve 19 of the branch road are closed. In the running state, the air-cooled evaporator 5 does not participate in the operation of the entire system at this time, and the circulation loop where the tube-fin evaporator 2 is located undertakes the entire operation of the system, and the medium is heated after the solar collector 1 collects solar radiation energy , the heated medium is transported to the tube-fin evaporator 2 through the pipeline, and exchanges heat with the refrigerant in the refrigerant pipe in the tube-fin evaporator 2, and the heated refrigerant enters ...

Embodiment 3

[0049] Inclement weather conditions and operation at night:

[0050] When the weather conditions are bad and the solar collector cannot operate normally at night, the fourth shut-off valve 17 and the second shut-off valve 18 on the main road are in operation, and the first shut-off valve 4 and the third shut-off valve 19 on the branch road are in the closed state , at this time, the loop where the air-cooled evaporator 5 is located starts to run, the fan is in the starting state, sucks in the air volume in the outside air, and is heated by an electric heating wire to generate hot air with a certain speed, which enters the air duct structure and enters the evaporator 5 The heat exchange between the hot air and the low-temperature refrigerant is realized, and finally the cold air is discharged, so that the low-temperature and low-pressure liquid refrigerant evaporates in the evaporator 5, and the refrigerant after evaporating and absorbing heat changes from a low-pressure liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com