Nanometer light guide plate, method for preparing nanometer light guide plate and display device

A nano-light guide plate and light guide plate technology, applied in the field of light guide plates, can solve the problems that the finished product cannot be cut at will, the production cost increases, and the equipment is complicated, etc., and achieve the effects of promoting and applying, enhancing applicability, and high light conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

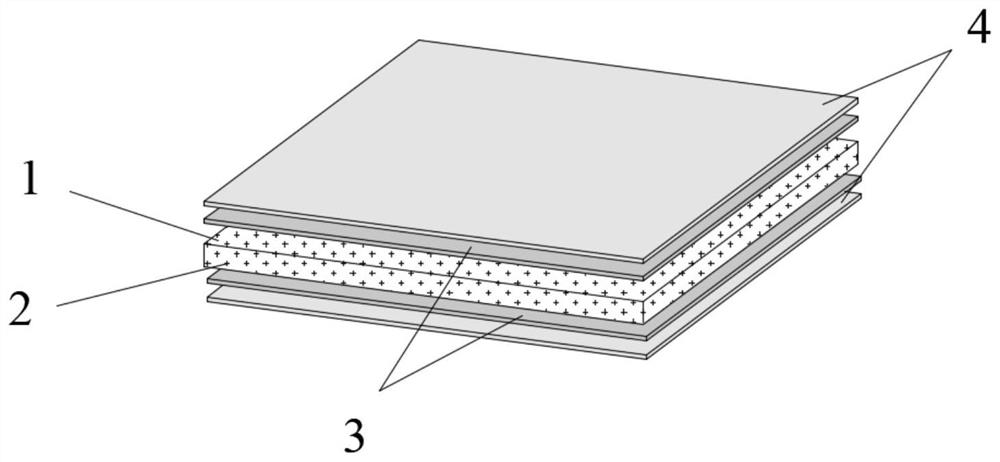

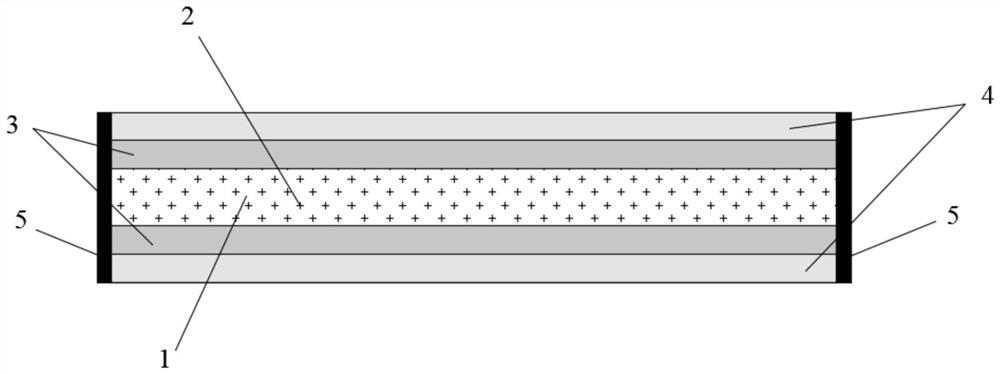

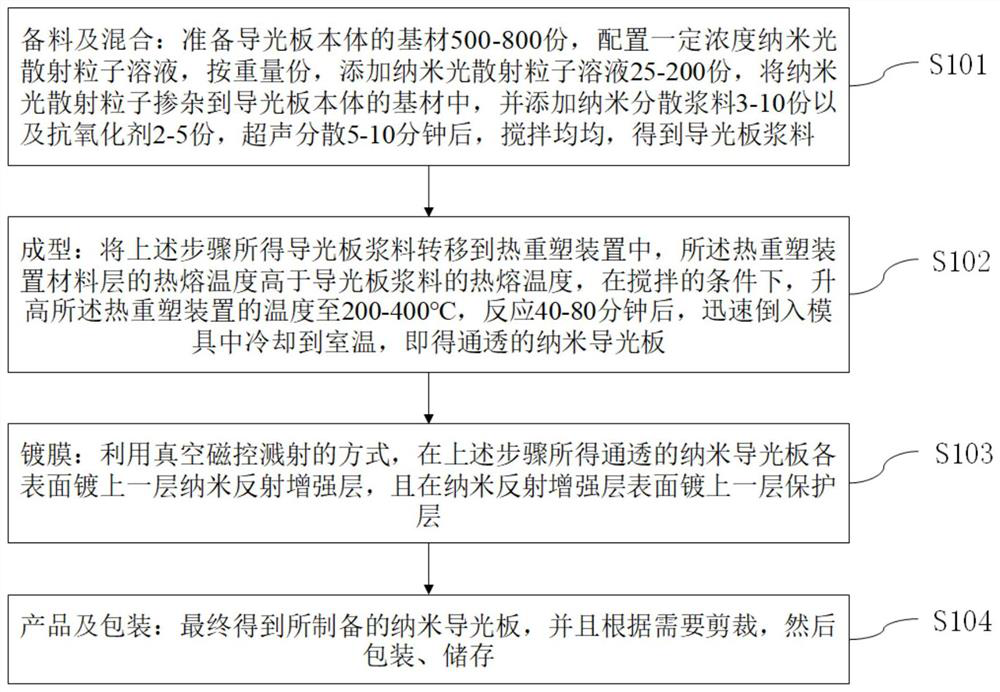

[0027] A nano light guide plate, comprising a light guide plate body 1 with a thickness of 0.8mm, the base material of the light guide plate body 1 is polycarbonate, and uniformly dispersed nano light scattering particles 2 are doped in the light guide plate body 1, and also Including nano-dispersed slurry and antioxidant, the upper surface and the lower surface of the light guide plate body 1 are respectively provided with a nano-reflection enhancement layer 3 with a thickness of 30 μm, and the side of the nano-reflection enhancement layer 3 away from the light guide plate body 1 is provided with a thickness of The protective layer 4 is 50 μm. In this embodiment, the nano-light scattering particles 2 are nano-silicon dioxide with a particle size of 20 nm, the nano-reflection enhancement layer 3 is a transparent material, and the protective layer 4 is pure PET plastic. 1 is surrounded by sidewalls 5, and the sidewalls 5 cover the nano-reflection enhancement layer 3 and the prot...

specific Embodiment 2

[0034] A nano light guide plate, comprising a light guide plate body 1 with a thickness of 10 mm, the base material of the light guide plate body 1 is polystyrene, uniformly dispersed nano light scattering particles 2 are doped in the light guide plate body 1, and it also includes The nano-dispersed slurry and the antioxidant are provided with a nano-reflection enhancement layer 3 with a thickness of 60 μm on the upper surface and the lower surface of the light guide plate body 1, and a thickness of 60 μm is provided on the side of the nano-reflection enhancement layer 3 away from the light guide plate body 1. The protective layer 4 is 120 μm. In this embodiment, the nano-light scattering particles 2 are nano-alumina with a particle size of 300 nm, the nano-reflection enhancing layer 3 is a transparent material, and the protective layer 4 is pure PET plastic. There are sidewalls 5 all around, and the sidewalls 5 cover the nano-reflection enhancement layer 3 and the protective l...

specific Embodiment 3

[0041]A nano light guide plate, comprising a light guide plate body 1 with a thickness of 5 mm, the base material of the light guide plate body 1 is polymethyl methacrylate, and uniformly dispersed nano light scattering particles 2 are doped in the light guide plate body 1, It also includes nano-dispersed slurry and antioxidant, and a nano-reflection enhancement layer 3 with a thickness of 50 μm is respectively provided on the upper surface and the lower surface of the light guide plate body 1, and the nano-reflection enhancement layer 3 is provided on the side away from the light guide plate body 1. There is a protective layer 4 with a thickness of 100 μm. In this embodiment, the nano-light scattering particles 2 are nano-titanium dioxide with a particle size of 100 nm, the nano-reflection enhancement layer 3 is a transparent material, and the protective layer 4 is pure PET plastic. 1 is surrounded by sidewalls 5, and the sidewalls 5 cover the nano-reflection enhancement layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com