Integrated hydraulic pump directly driven by slotless moving magnet type linear oscillation motor

A technology of oscillating motor and hydraulic pump, applied in the field of hydraulic pump, can solve the problems of reducing the reliability and stability of the whole machine operation, increasing the difficulty of assembling the electromagnetic direct drive pump, and being difficult to realize two-way drive, etc., so as to improve the heat dissipation efficiency and limit work. capacity, is conducive to the layout of the external cooling system, and is conducive to the effect of miniaturized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

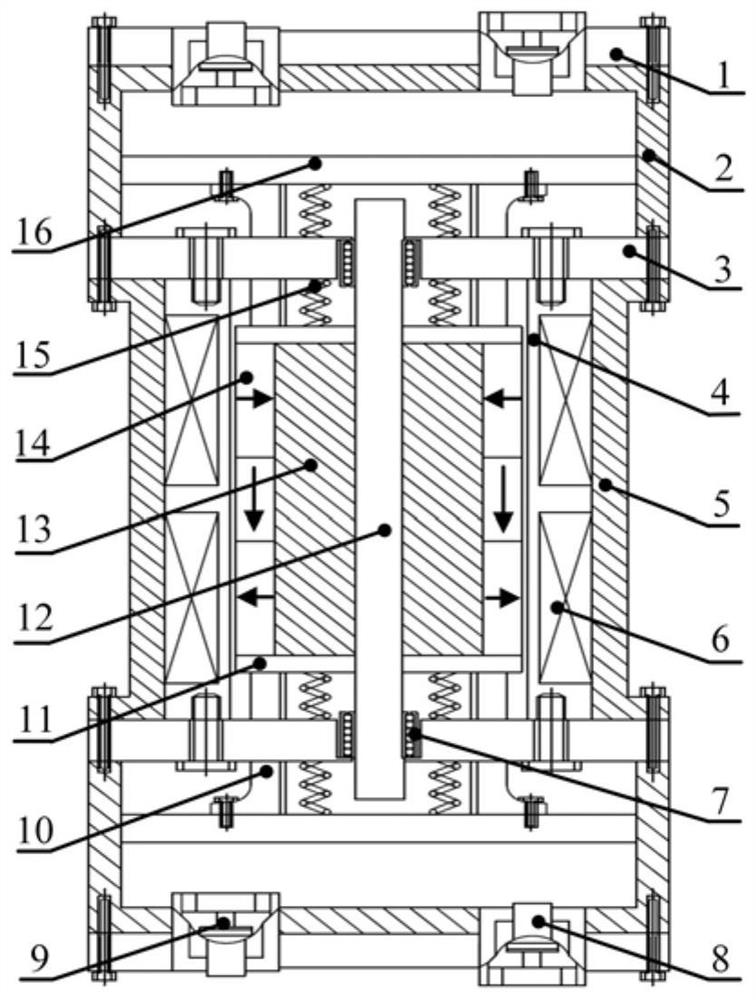

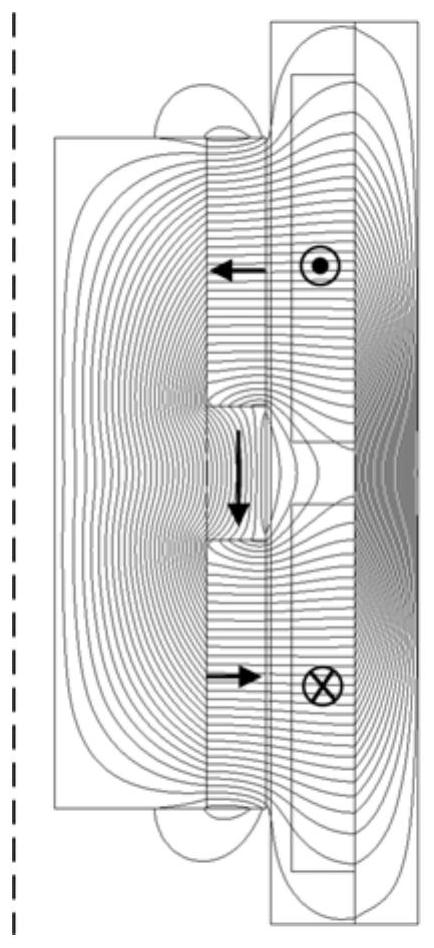

[0041] Such as figure 1 As shown, an integrated hydraulic pump directly driven by a slotless moving magnet linear oscillating motor includes: a hydraulic pump stator, a hydraulic pump mover and a resonant spring 15 arranged in the hydraulic pump stator, and the resonant spring 15 is connected to the hydraulic pump motor child connected. The stator of the hydraulic pump consists of two valve bodies 1, two hydraulic cylinders 2, two end covers 3, a coil skeleton 4, an outer yoke 5, an electromagnetic coil group 6, a liquid inlet check valve 8 and a liquid outlet check valve 9 composed of symmetrical structures. The mover of the hydraulic pump is composed of two piston connecting bodies 10 , two magnetic isolation protection rings 11 , a drive shaft 12 , a mover yoke 13 , a permanent magnet array 14 and two pistons 16 . A liquid inlet check valve 8 and a liquid outlet check valve 9 are respectively installed on the upper and lower valve bodies 1 . The materials of the outer yo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com