Flow focusing type one-step-process double-emulsion-droplet parallel generation device and method

A technology for generating devices and double emulsions, applied in chemical instruments and methods, fluid controllers, laboratory containers, etc., can solve the problems of increasing the difficulty of designing and manufacturing flow channels, increasing the pressure of inlet and flow channels, and complex chip structures , to achieve the effect of shortening the production cycle, not easy to block, and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

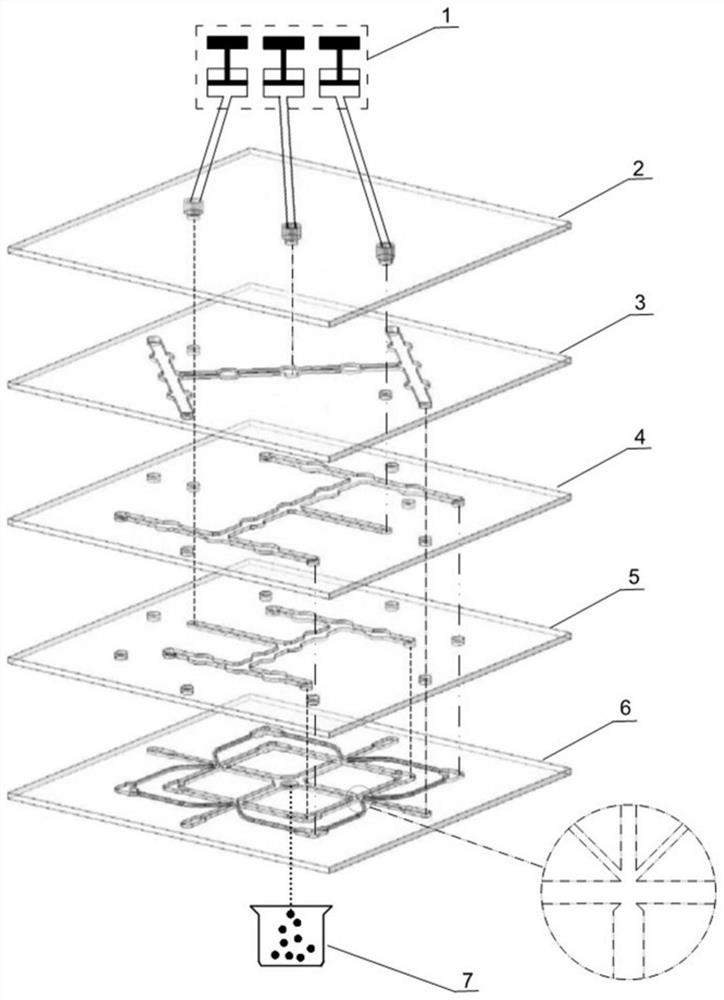

[0043] see Figure 1-Figure 7 , the present invention's one-step double-emulsion parallel generation device based on flow focusing type includes a fluid injection module 1, a droplet generation module, a droplet surface solidification module, and a droplet collection module 7, wherein,

[0044] The fluid injection module 1 is used to deliver internal phase fluid, intermediate phase fluid and external phase fluid to the droplet generation module, including internal phase fluid injection pumps, intermediate phase fluid injection pumps and external phase fluid injection pumps;

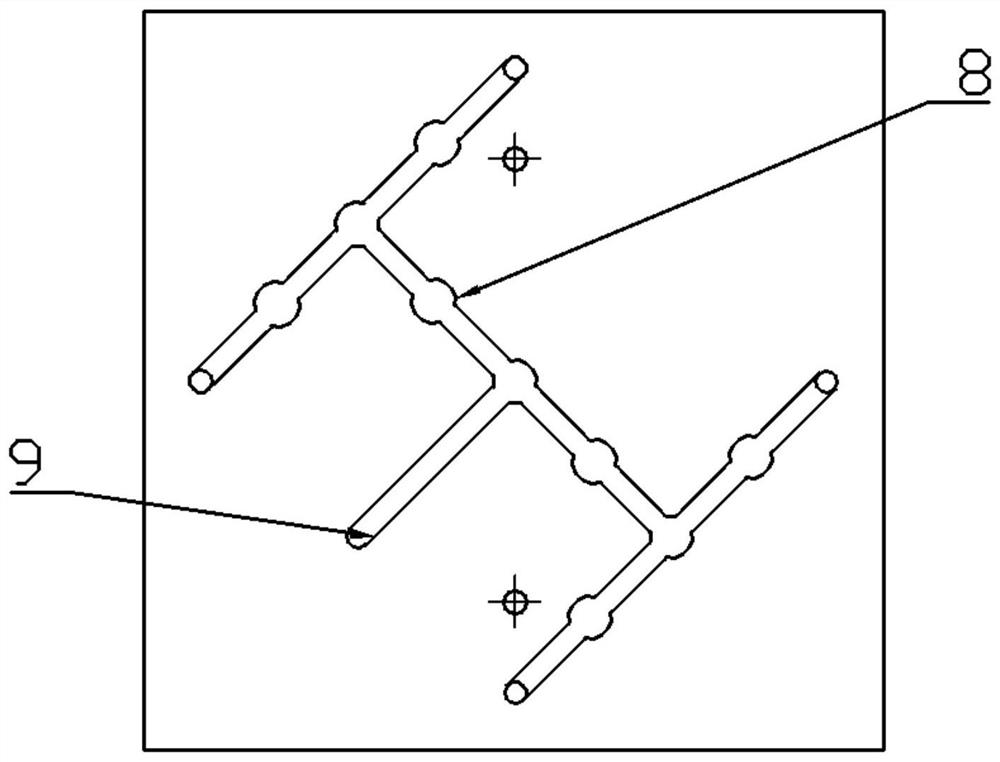

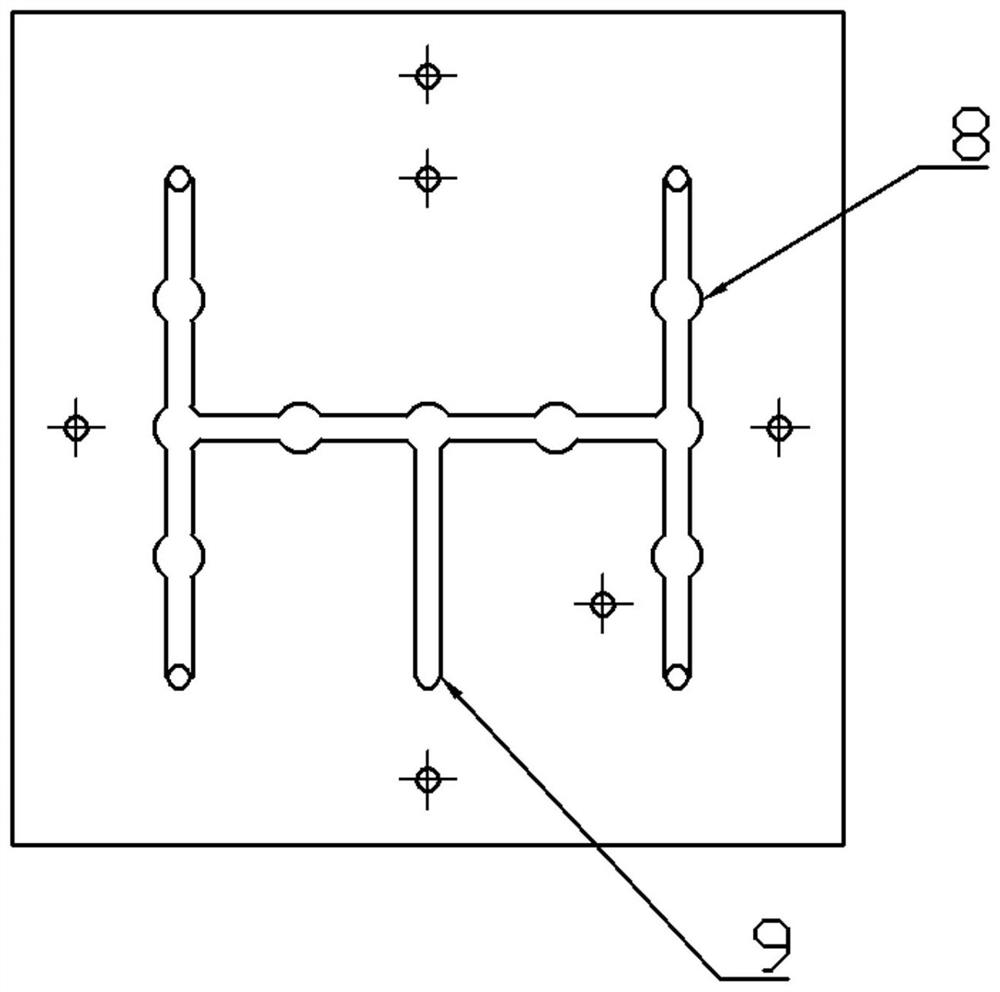

[0045] The droplet generating module includes a fluid distribution functional area, a droplet preparation functional area and an auxiliary functional area, wherein the auxiliary functional area is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com