Plate positioning drilling system and positioning method

A technology for plates and drills, applied in positioning devices, boring/drilling, chemical instruments and methods, etc., can solve problems affecting drilling processing efficiency and achieve the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

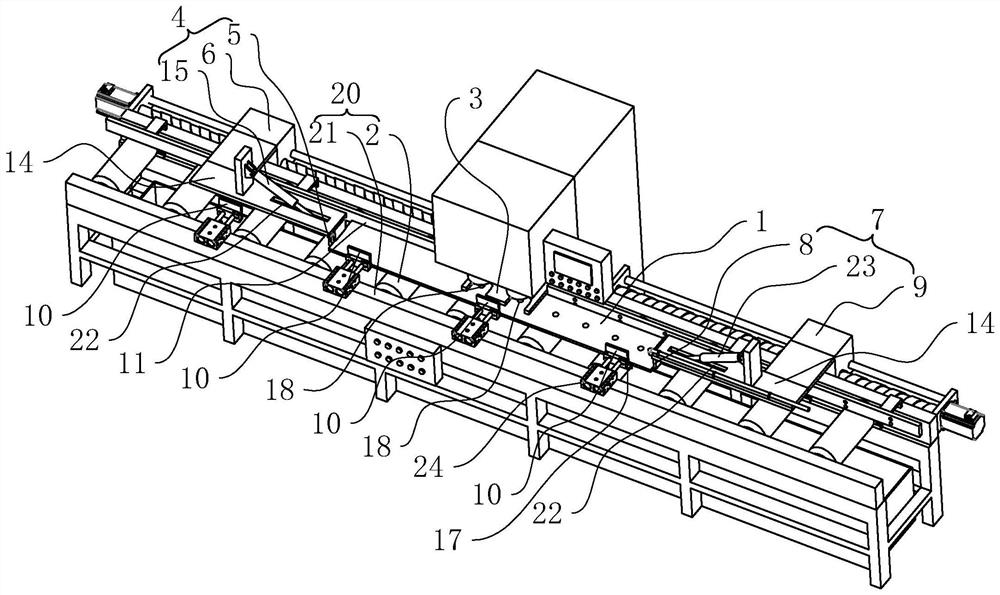

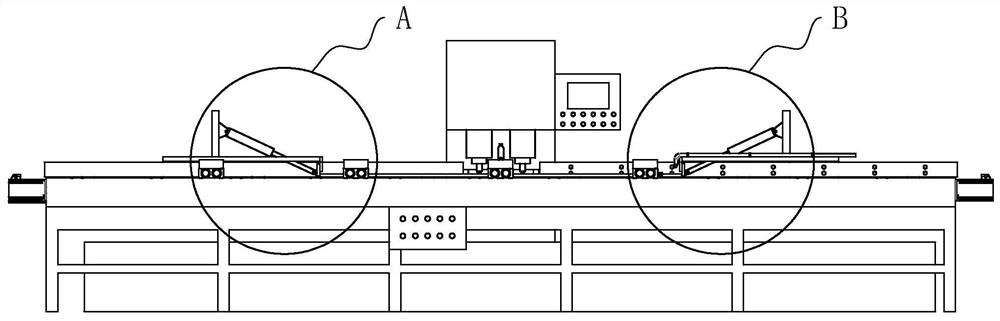

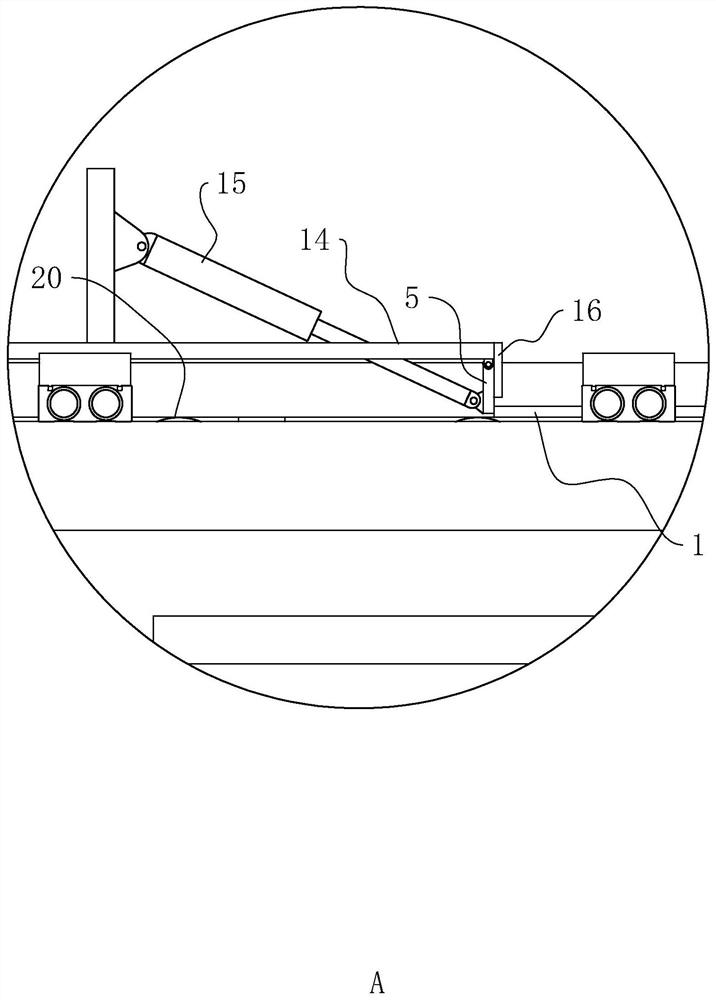

[0043] The following is attached Figure 1-6 The application is described in further detail.

[0044] The embodiment of the present application discloses a plate positioning drilling system. refer to figure 1 The plate 1 positioning drilling system includes a drill bit 18, a linear transmission line 20 located directly below the drill bit 18, a second pusher plate 10, a second material blocking plate 11, and a pressure plate 3 located on both sides of the linear transmission line 20. , Pushing mechanism 4 and blocking mechanism 7, wherein drill bit 18 is positioned at the side of pressing plate 3, and drilling bit 18, holding plate 3, the second pushing plate 10 and the second blocking plate 11 are all positioned at pushing mechanism 4 and blocking Between the feeding mechanism 7.

[0045] refer to figure 1 , the clamping plate 3 is used to press the plate 1 on the linear transmission line 20 so that the drill bit 18 can drill holes; Push the plate 1 to move along the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com