Water reducing agent and preparation method thereof

A technology of water reducing agent and sulfonating agent, which is applied in the field of water reducing agent and its preparation, and can solve problems such as low production efficiency, long production cycle, and difficult temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

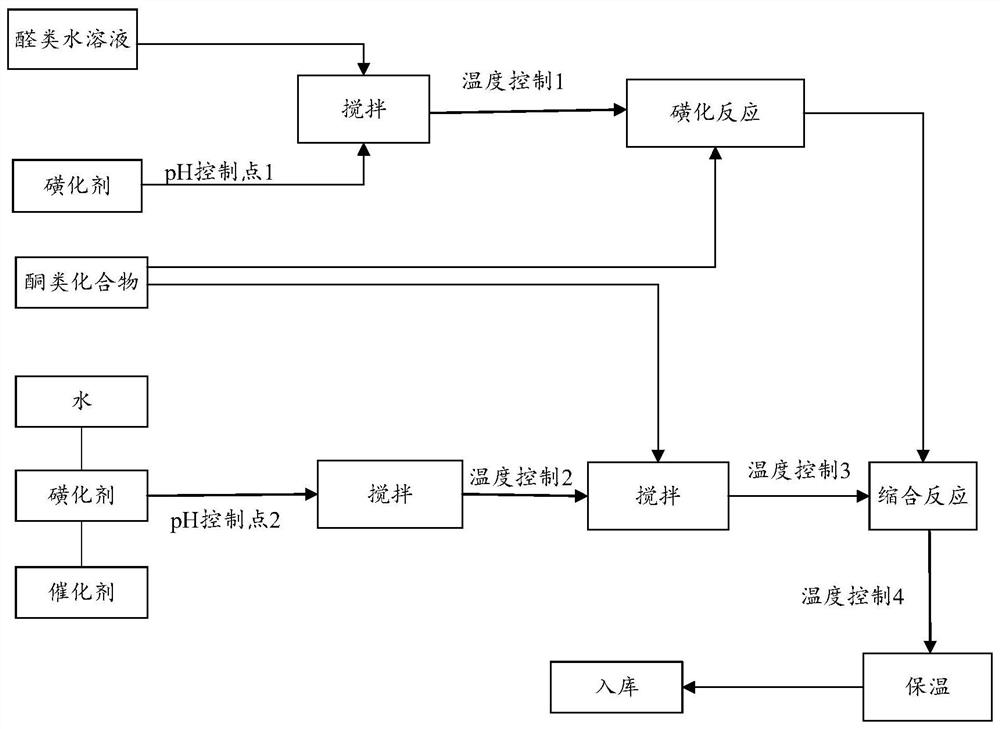

[0036] ginseng figure 1 , the invention provides a kind of preparation method of water reducing agent, it comprises the following steps:

[0037] Provide ketone compounds, aldehyde compounds, sulfonating agents, and catalysts, wherein the mass ratio of ketone compounds, aldehyde aqueous solutions, sulfonating agents, and catalysts is 100:260-300:95-130:15-25, In the aldehyde aqueous solution, the content of aldehyde compounds is 30-40%;

[0038] Dissolve 50-80% of the sulfonating agent in water, add an aqueous aldehyde solution, and stir for 5-10 minutes to obtain the first mixed solution;

[0039] Adding 50-80% of ketone compounds into the first mixed solution to carry out sulfonation reaction to obtain a pre-sulfonation solution;

[0040] Dissolve the remaining sulfonating agent and catalyst in water, and stir for 10-20 minutes to obtain the second mixed solution;

[0041] adding the remaining ketone compound into the second mixed solution, and stirring for 10-30 minutes ...

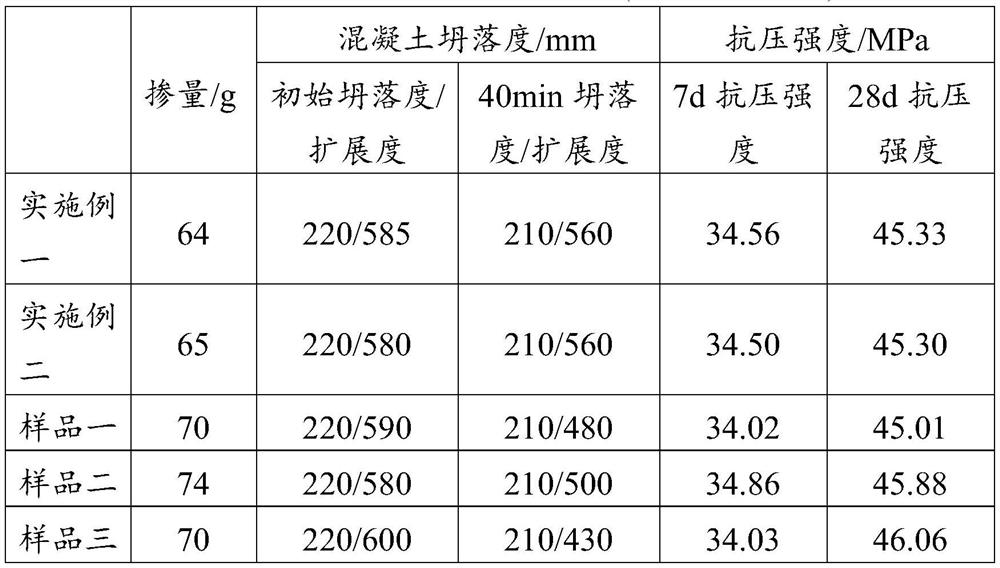

Embodiment 1

[0072] 1. Provide 50.0g of acetone, 141.0g of formaldehyde solution (formaldehyde content 37%), 58.5g of sodium bisulfite (97.5%), and 8.5g of sodium hydroxide;

[0073] 2. The preparation process is as follows:

[0074] Step 1: 35.9 g of sodium bisulfite is dissolved in 85.0 g of water, and 141.0 g of formaldehyde solution with a content of 37% is added to obtain the first mixed solution; the first mixed solution is cooled so that the temperature of the first mixed solution Decrease to below 32°C; add 35.0 g of acetone to the first mixed solution to obtain a pre-sulfonated solution;

[0075] Step 2: Add 22.6 g of sodium bisulfite, 8.5 g of sodium hydroxide, and 100.0 g of water in a four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir and dissolve to obtain the second mixed solution; The second mixed solution is cooled so that the temperature of the second mixed solution is less than 40° C.; 15.0 g of acetone is added to the second mixed ...

Embodiment 2

[0079] 1. Provide 50.0g of acetone, 151.0g of formaldehyde solution (formaldehyde content 37%), 53.7g of sodium metabisulfite (100%), and 8.5g of sodium hydroxide;

[0080] 2. The preparation process is as follows:

[0081] Step 1: dissolving 32.7g of sodium metabisulfite in 89.8g of water, adding 151.0g of formaldehyde solution with a content of 37%, to obtain the first mixed solution; cooling the first mixed solution so that the temperature of the first mixed solution is reduced to Below 32°C; add 36.0 g of acetone to the first mixed solution to obtain a pre-sulfonated solution;

[0082] Step 2: Add 21 g of sodium metabisulfite, 8.5 g of sodium hydroxide, and 90.0 g of water into a four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to dissolve to obtain the second mixed solution; for the second mixed solution Perform cooling treatment so that the temperature of the second mixed solution is less than 40° C.; add 14.0 g of acetone to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com