Light fireproof curtain wall

A fire curtain, lightweight technology, applied in the direction of fire prevention, walls, building components, etc., can solve the problems of insufficient crushing, equipment damage, material size is not uniform enough, etc., to achieve the effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A lightweight fireproof curtain wall is made by the following steps:

[0047] S1. Weigh the raw materials, and weigh the following raw materials in parts by weight: 70 parts of polystyrene foam, 15 parts of clay, 13 parts of silicon dioxide, 20 parts of talcum powder, 15 parts of quartz sand, and 15 parts of ammonium sulfate. 5 parts, 10 parts of sodium bicarbonate and 20 parts of water;

[0048] S2, pulverize, polystyrene foam is put into pulverizing equipment and pulverizes, and pulverizes to particle diameter and is 2mm; The specific operation steps of pulverizing equipment are:

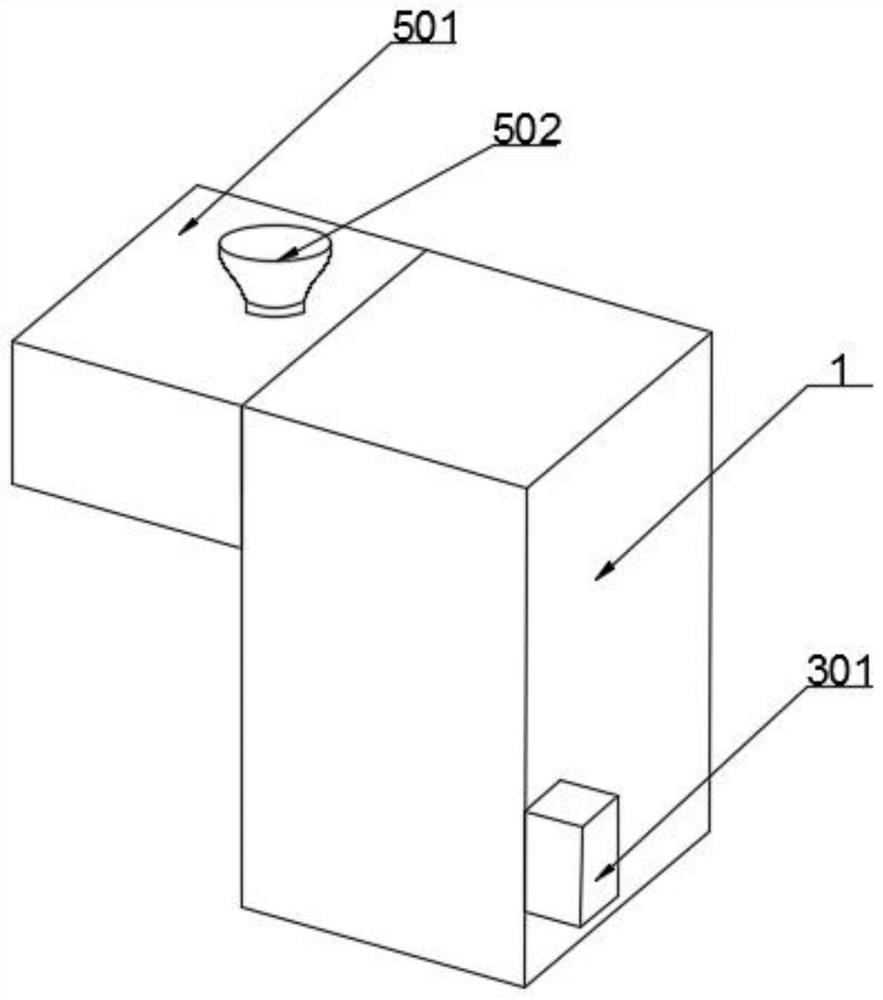

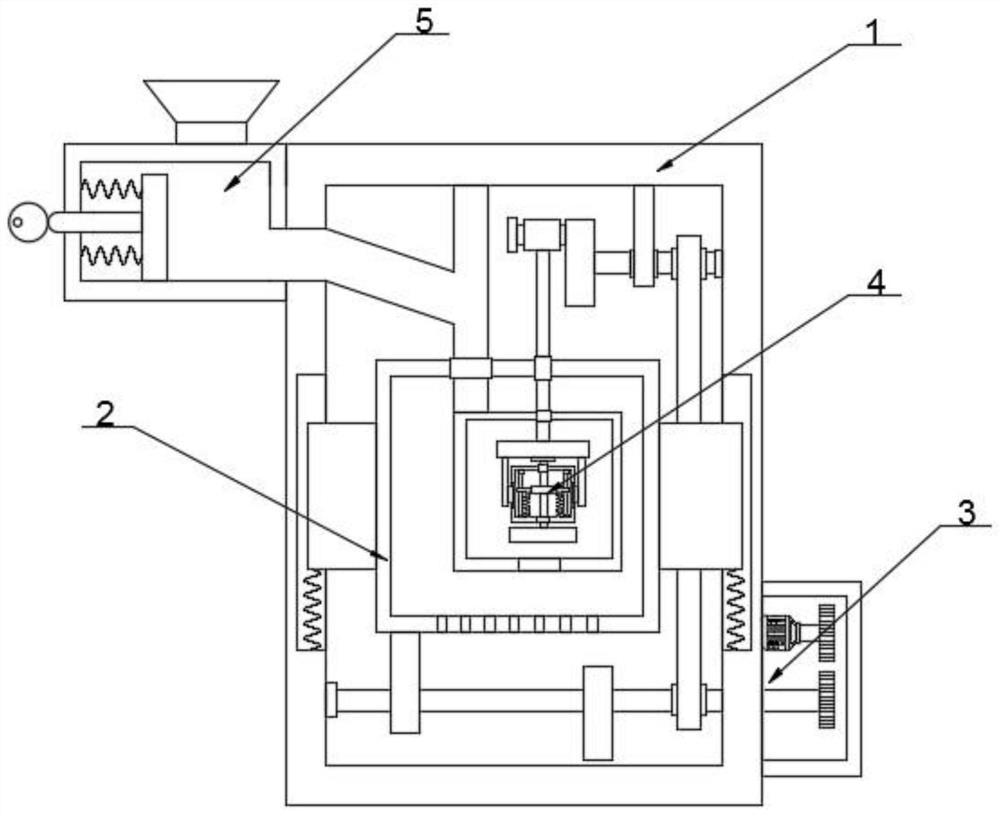

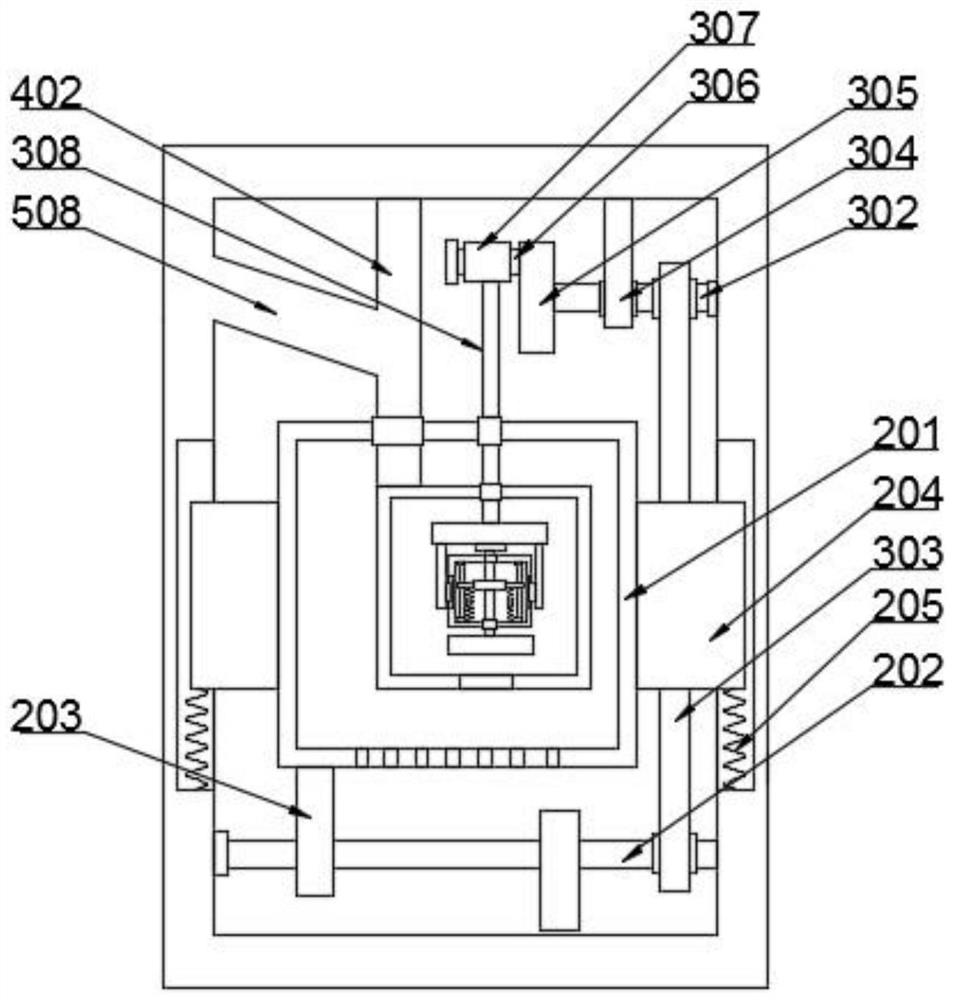

[0049] The first step is to put the material from the feed hopper 502 into the inside of the feed chamber 501, start the second motor 503, drive the second eccentric disk 504 to rotate, and drive the push rod 506 to move to the inside of the feed chamber 501, thereby Push the pusher plate 505 to push the material, so that the material enters the inside of the second support rod 402 from th...

Embodiment 2

[0058] A lightweight fireproof curtain wall is made by the following steps:

[0059] S1. Weigh the raw materials, and weigh the following raw materials in parts by weight: 85 parts of polystyrene foam, 12 parts of clay, 14 parts of silicon dioxide, 22 parts of talcum powder, 17 parts of quartz sand, and 17 parts of ammonium sulfate. 8 parts, 12 parts of sodium bicarbonate and 22 parts of water;

[0060] S2, pulverize, polystyrene foam plastic is put into pulverizing equipment and pulverizes, and pulverizes to particle diameter and is 2.5mm; The specific operation steps of pulverizing equipment are:

[0061] The first step is to put the material from the feed hopper 502 into the inside of the feed chamber 501, start the second motor 503, drive the second eccentric disk 504 to rotate, and drive the push rod 506 to move to the inside of the feed chamber 501, thereby Push the pusher plate 505 to push the material, so that the material enters the inside of the second support rod 4...

Embodiment 3

[0070] A lightweight fireproof curtain wall is made by the following steps:

[0071] S1. Weigh the raw materials, and weigh the following raw materials in parts by weight: 100 parts of polystyrene foam, 15 parts of clay, 16 parts of silicon dioxide, 25 parts of talcum powder, 19 parts of quartz sand, and 15 parts of ammonium sulfate. 10 parts, 13 parts of sodium bicarbonate and 25 parts of water;

[0072] S2, pulverize, polystyrene foam plastic is put into pulverizing equipment and pulverizes, and pulverizes to particle diameter and is 3mm; The specific operation steps of pulverizing equipment are:

[0073] The first step is to put the material from the feed hopper 502 into the inside of the feed chamber 501, start the second motor 503, drive the second eccentric disk 504 to rotate, and drive the push rod 506 to move to the inside of the feed chamber 501, thereby Push the pusher plate 505 to push the material, so that the material enters the inside of the second support rod 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com