A kind of low-odor automobile grease composition and preparation method thereof

A technology of automobile lubrication and composition, which is applied in the field of low-odor automobile grease composition and its preparation, and achieves the effects of good anti-wear and friction-reducing properties, good compatibility and good colloidal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

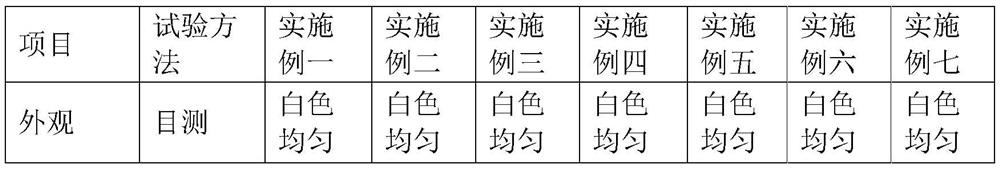

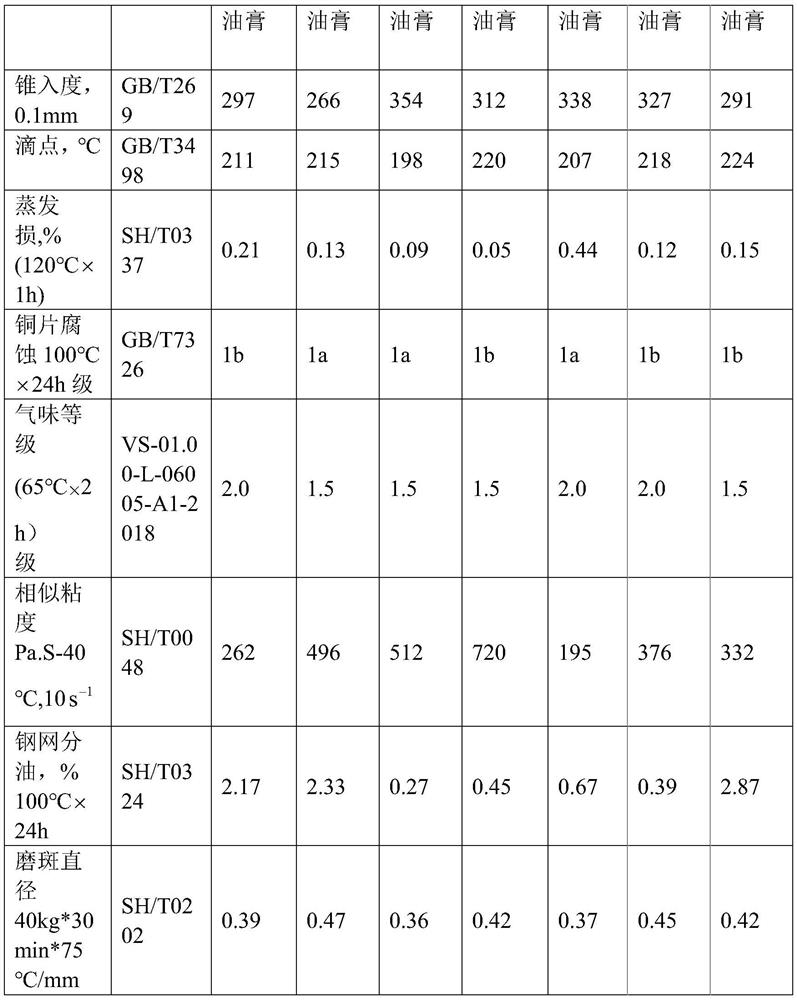

Examples

Embodiment 1

[0036]1) Clean the used reaction kettle, three-roll mill and other preparation tools for use.

[0037] 2) 40 parts of polyalpha-olefin oil (V40=32.5mm 2 / s) and 12 parts of stearic acid (saponification value=210) were added in the reactor successively, after 5 minutes of stirring, 1.98 parts of lithium hydroxide monohydrate (lithium hydroxide content=57.1%) and 5 parts were added successively deionized water, close the lid of the kettle, open the inlet and exhaust valves, and pass nitrogen into the reactor, the nitrogen pressure is 0.12-0.20Mpa, the time lasts 10±2 minutes, completely remove the air in the kettle, and then close the inlet and exhaust. Air valve, start to heat up and increase the pressure. When the pressure of the reactor reaches 0.4MPa, start the constant temperature and constant pressure timing, the constant temperature and pressure time is 120±5 minutes, and the pressure is 0.4-0.45MPa.

[0038] 3) After the constant temperature and pressure is over, start ...

Embodiment 2

[0042] 1) Clean the used reaction kettle, three-roll mill and other preparation tools for use.

[0043] 2) 39 parts of polyalpha-olefin oil (V40=66.9mm 2 / s) and 15 parts of stearic acid (saponification value=212) were added in the reactor successively, after 5 minutes of stirring, 2.48 parts of lithium hydroxide monohydrate (lithium hydroxide content=57.0%) and 7.5 parts were added successively deionized water, close the lid of the kettle, open the inlet and exhaust valves, and pass nitrogen into the reactor, the nitrogen pressure is 0.12-0.20Mpa, the time lasts 10±2 minutes, completely remove the air in the kettle, and then close the inlet and exhaust. Air valve, start to heat up and increase the pressure. When the pressure of the reactor reaches 0.4MPa, start the constant temperature and constant pressure timing, the constant temperature and pressure time is 120±5 minutes, and the pressure is 0.4-0.45MPa.

[0044] 3) After the constant temperature and pressure is over, sta...

Embodiment 3

[0048] 1) Clean the used reaction kettle, three-roll mill and other preparation tools for use.

[0049] 2) 42 parts of polyalpha-olefin oil (V40=99.3mm 2 / s) and 7 parts of stearic acid (saponification value=209) were added in the reactor successively, after 5 minutes of stirring, 1.16 parts of lithium hydroxide monohydrate (lithium hydroxide content=56.8%) and 3 parts were added successively deionized water, close the lid of the kettle, open the inlet and exhaust valves, and pass nitrogen into the reactor, the nitrogen pressure is 0.12-0.20Mpa, the time lasts 10±2 minutes, completely remove the air in the kettle, and then close the inlet and exhaust. Air valve, start to heat up and increase the pressure. When the pressure of the reactor reaches 0.4MPa, start the constant temperature and constant pressure timing, the constant temperature and pressure time is 120±5 minutes, and the pressure is 0.4-0.45MPa.

[0050] 3) After the constant temperature and pressure is over, start ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com