Electrostatic spinning device capable of preparing core-shell structure nanofibers in batches

An electrospinning, core-shell structure technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve pinhole blockage, low fiber film output, affect the continuity and stability of spinning process, etc. problem, to achieve the effect of simple structure, improved continuity and stability, convenient and quick structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

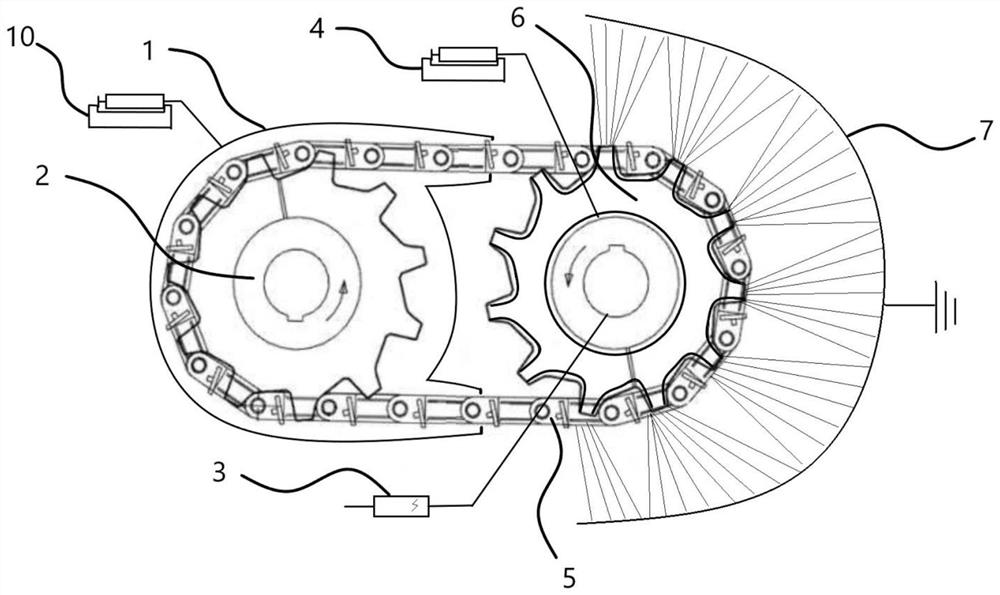

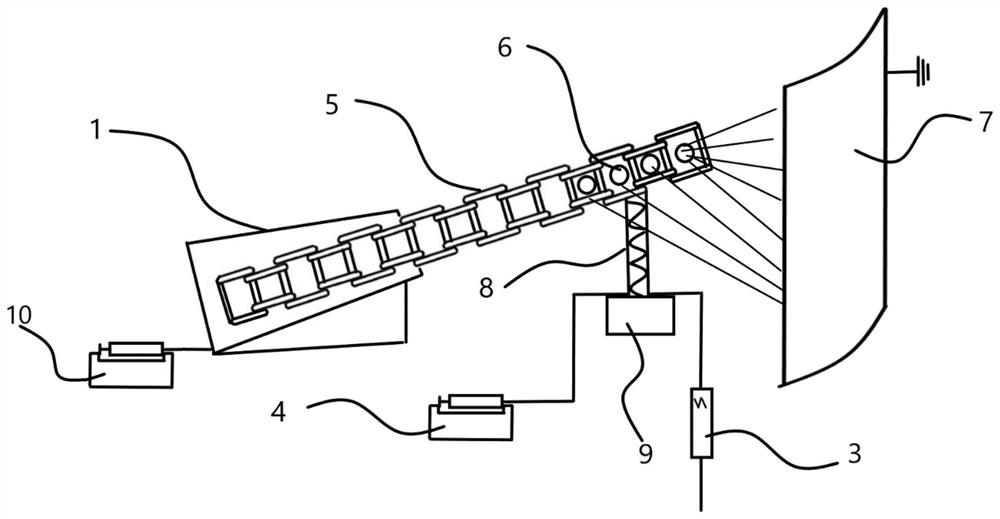

[0020] See figure 1 and figure 2 , an electrospinning device capable of preparing core-shell structure nanofibers in batches in a preferred embodiment of the present invention, which includes a liquid storage tank 1, a first gear 2 arranged in the liquid storage tank 1, a first gear 2 arranged in the storage tank The second gear 6 outside the liquid pool 1, the chain 5 used to connect the first gear 2 and the second gear 6, and the driving liquid supply mechanism used to drive the second gear 6 to rotate, and the driving liquid supply mechanism to drive the second gear 6 rotates and then drives the chain 5 to rotate, so as to drive the first gear 2 in the liquid storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com