Long-stroke pumping unit installed at wellhead and underground sealing device

A technology of sealing device and pumping unit, which is applied in the direction of sealing/isolation, wellbore/well components, and production fluid, etc., which can solve the problems of wellhead sealing material leakage, increase of loss speed, and impact on production, and achieve good sealing effect, Ease of application, reduced wear and aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

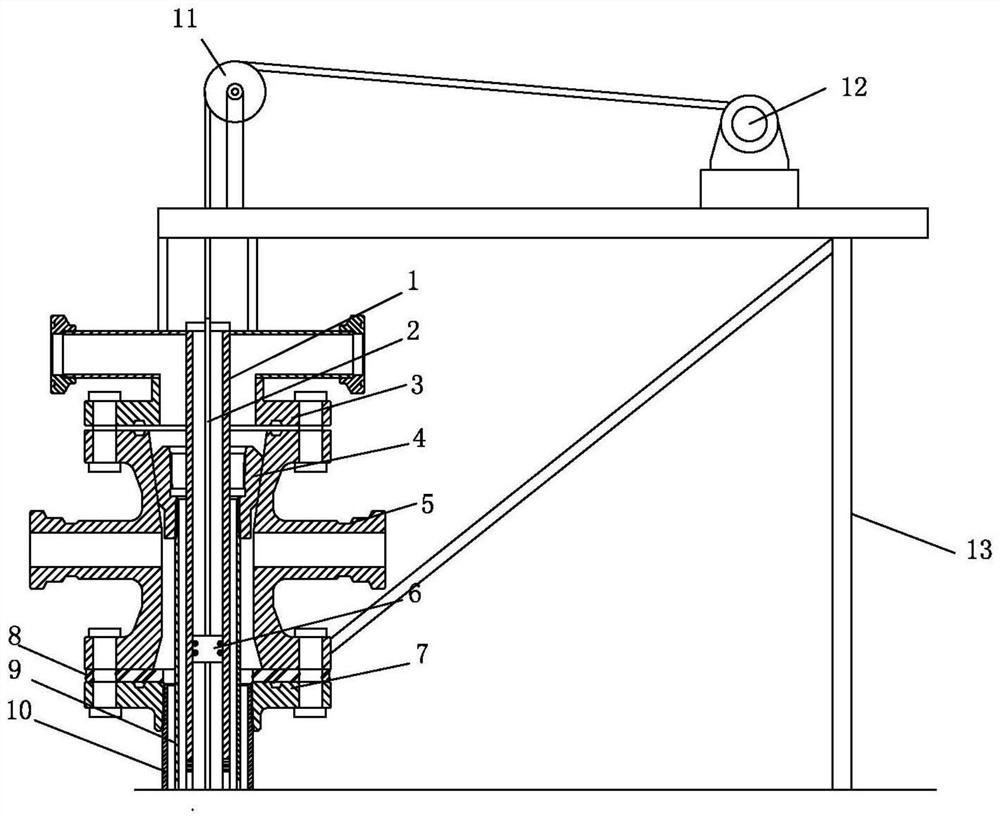

[0022] This embodiment provides a specific structure of a long-stroke pumping unit installed at the wellhead and a downhole sealing device, such as figure 1 As shown, it includes the large cross 5 and the bracket 13 installed on the equipment base 8, the middle part of the large cross 5 is interspersed with a sealing working cylinder 1, and the sealing sliding piston 6 is installed inside the sealing working cylinder 1, and the sealing sliding piston 6 A steel wire rope 2 is interspersed on the top.

[0023] The bracket 13 has an inverted L-shaped structure. A pulley assembly 11 and a long-stroke pumping unit 12 are installed above the horizontal end of the bracket 13. The pulley assembly 11 is located above the sealed working cylinder 1. One end of the wire rope 2 goes around the pulley assembly 11 and enters the long-stroke pumping unit. The interior of the stroke pumping unit 12.

[0024] The top of the big four-way 5 is also equipped with an oil well sealing device 3.

...

Embodiment 2

[0031] This embodiment provides a specific structure of a long-stroke pumping unit installed at the wellhead and a downhole sealing device, such as figure 1 As shown, it includes the large cross 5 and the bracket 13 installed on the equipment base 8, the middle part of the large cross 5 is interspersed with a sealing working cylinder 1, and the sealing sliding piston 6 is installed inside the sealing working cylinder 1, and the sealing sliding piston 6 A steel wire rope 2 is interspersed and installed on the top;

[0032] The bracket 13 has an inverted L-shaped structure. A pulley assembly 11 and a long-stroke pumping unit 12 are installed above the horizontal end of the bracket 13. The pulley assembly 11 is located above the sealed working cylinder 1. One end of the wire rope 2 goes around the pulley assembly 11 and enters the long-stroke pumping unit. The interior of the stroke pumping unit 12.

[0033] The top of the big four-way 5 is also equipped with an oil well sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com