An oil and gas wellhead high-efficiency energy-saving explosion-proof electromagnetic heater

A technology for oil and gas and electromagnetic heaters, which is applied in pipeline heating/cooling, heat exchange equipment, and pipeline protection through heat insulation. It can solve problems such as uneven oil temperature and affect heating effects, so as to improve heating efficiency and improve heating efficiency. effect, the effect of maintaining airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

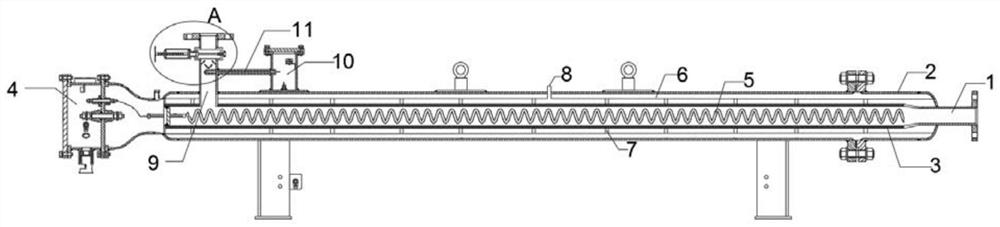

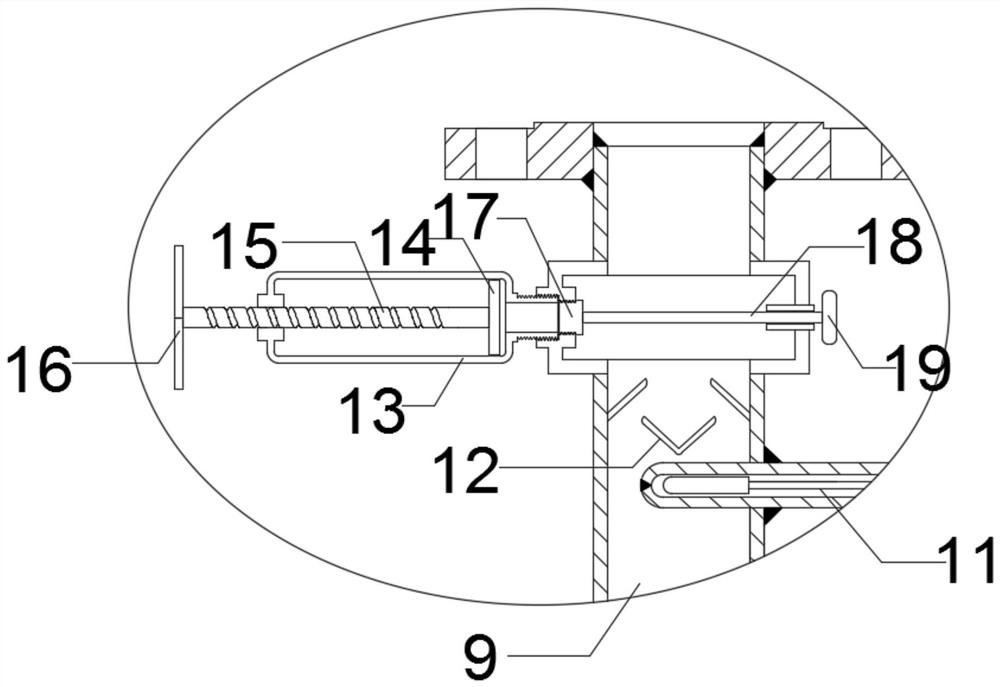

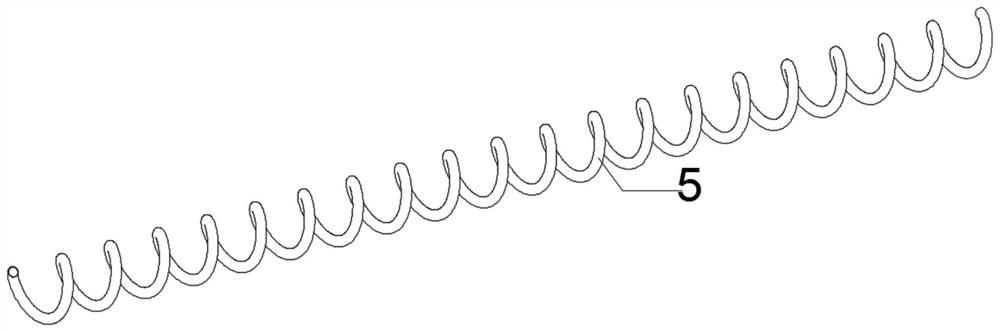

[0024] see Figure 1-3 , this embodiment provides an oil and gas wellhead high-efficiency energy-saving explosion-proof electromagnetic heater, including a liquid inlet pipe 1, an explosion-proof heating shell 2, a heating layer 3, an explosion-proof junction box 4, and a heating tube 5; the inside of the explosion-proof heating shell 2 There is a heating layer 3 for heating the oil, and one end of the heating layer 3 communicates with the liquid inlet pipe 1 for inputting oil; The oil outlet pipe 9 communicates; the heating layer 3 is provided with a heating pipe 5; the heating pipe 5 is a hollow pipe, and the shape of the heating pipe 5 is spring-shaped; The heating strip, and the gap between the heating strip and the inner wall of the heating tube 5 is filled with a heat medium conduction medium; the explosion-proof junction box 4 that is electrically connected to the heating strip and controls the operation of the heating strip is arranged on one side of the explosion-proo...

Embodiment 2

[0033] This embodiment is further improved on the basis of Embodiment 1. The improvements are as follows: in order to facilitate the control of the amount of sampling, the transparent sampling cylinder 13 is provided with a scale; Poorly, the liquid outlet pipe 9 below the transparent sampling cylinder 13 is provided with a plurality of inclined plates 12 for disturbing the oil.

[0034] In order to detect the temperature of petroleum and natural gas in the liquid pipe 9, one side of the explosion-proof heating shell 2 is provided with an external overheating junction box 10, and the outer overheating junction box 10 is provided with an outlet medium temperature measuring thermal resistor 11 for detecting temperature; One end of the outlet medium temperature measuring thermal resistance 11 is arranged in the liquid outlet pipe 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com