Aero-engine high-altitude simulation test bed regulating valve automatic model selection method

An aero-engine and high-altitude simulation technology, which is applied in the field of aero-engines, can solve problems such as progress delays, heavy demand workload, and calculation errors, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

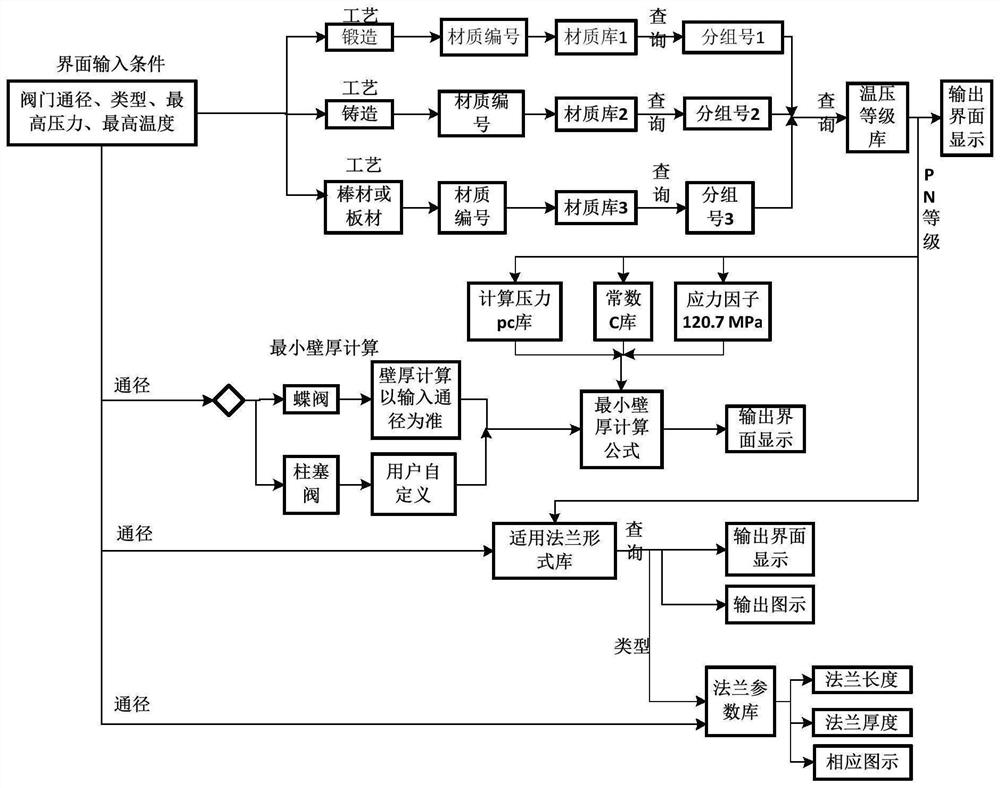

[0033] In order to solve the current situation of the lack of perfect and efficient air working environment simulation system control valve type selection analysis methods and tools in the construction of high-altitude test benches for aero-engines in my country. The invention proposes a whole-process type selection method for a regulating valve, and develops a set of automatic type selection tool software for a regulating valve based on the EN standard based on the Labview environment. Contains the following steps:

[0034] Step 1: According to the characteristics of the main test objects and test subjects of the high-altitude platform, analyze and summarize the limit boundary of the air intake and exhaust system for simulated air intake and exhaust systems, as the basis for subsequent type selection analysis.

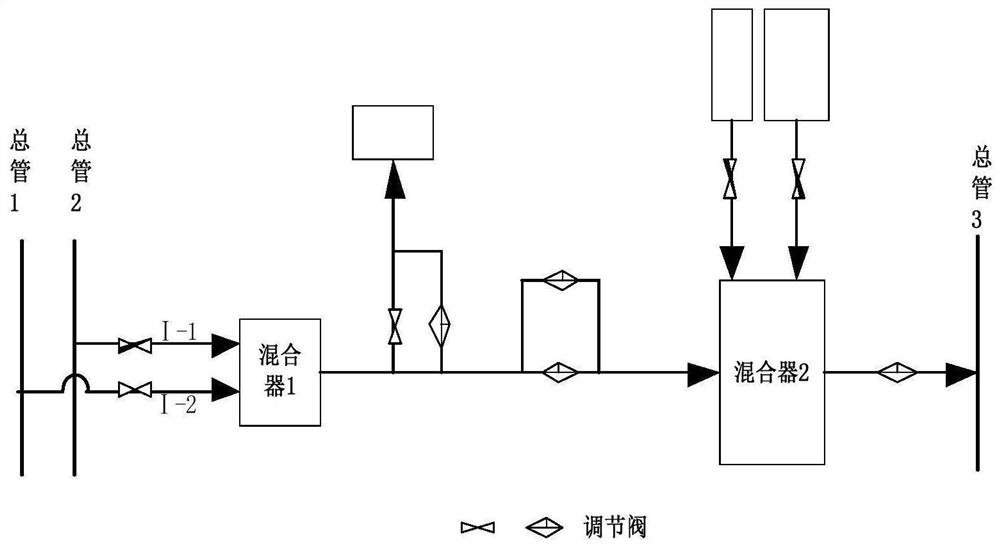

[0035] Step 2: Based on the design principle of the aerodynamic layout of the high-altitude cabin, and according to the summarized limit boundary condition requiremen...

Embodiment 2

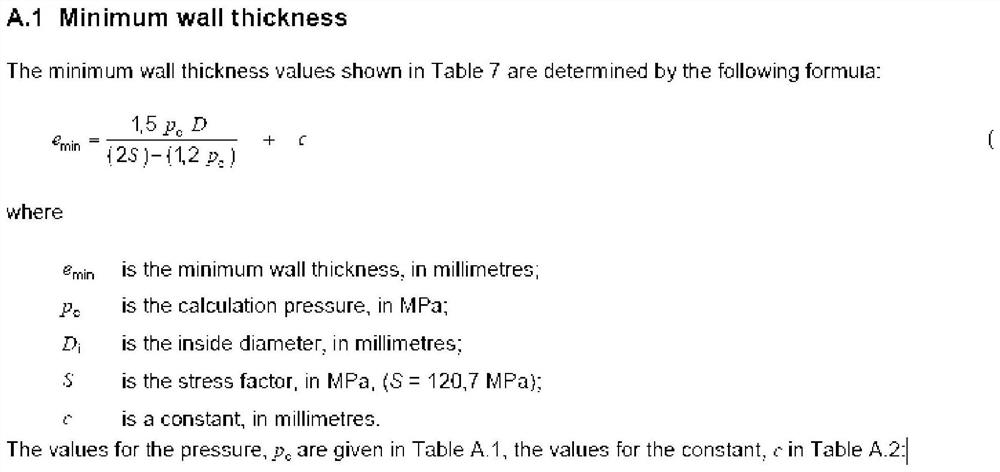

[0042] The specific process of this implementation case is: analyze the typical test points of the main test objects of a certain high-altitude simulation test bench to obtain the limit boundary of air intake and exhaust simulation demand pressure, temperature and flow adjustment. According to the principle of aerodynamic layout of the high-altitude test bench, to meet the requirements of the limit test point as the convergence condition, the working boundary of the control valve on the aerodynamic branch is calculated and analyzed, and the characteristic values such as limit temperature, pressure and flow range are extracted. Based on the feature extraction value, in the type selection software developed by the present invention, the EN series standards are used as the criterion to conduct type selection analysis on key indicators such as the material of the control valve, PN grade, wall thickness, flange and its parameters.

[0043]Step 1: According to the typical limit tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com