Pervious concrete proportion design method based on cement mortar density and wrapping performance

A technology for permeable concrete and cement mortar, applied in the directions of calculation, data processing application, instrument, etc., can solve the problems of tedious calculation process, cumbersome process, test, etc., and achieve the effect of simplifying the calculation process, strong practicability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The design method of permeable concrete mix ratio based on cement mortar density and coating performance, the specific process is as follows:

[0051] 1) Use 4.75 ~ 9.5mm single particle size aggregate, close packing density ρ g0 =1.700g / cm 3 , Aggregate dosage correction factor α = 0.98, per cubic meter of permeable concrete aggregate dosage is:

[0052] m g =α·ρ g0 =0.98×1.700g / cm 3 ×1m 3 =1666.0kg

[0053] aggregate apparent density ρ g =2.930g / cm 3 , design porosity V air =15%, glue volume V B for:

[0054]

[0055] 2) Prepare plain cement slurry with a water-cement ratio of 0.32, and the amount of cement is m C =800g, water consumption is m W = 256 g. Determine the density of the glue as ρ B =2.0346g / cm 3 . Calculation of the design glue dosage M B and design pulp set ratio R B / A :

[0056] m B =V B ·ρ B =0.2814m 3 ×2.0346g / cm 3 =572.5kg

[0057]

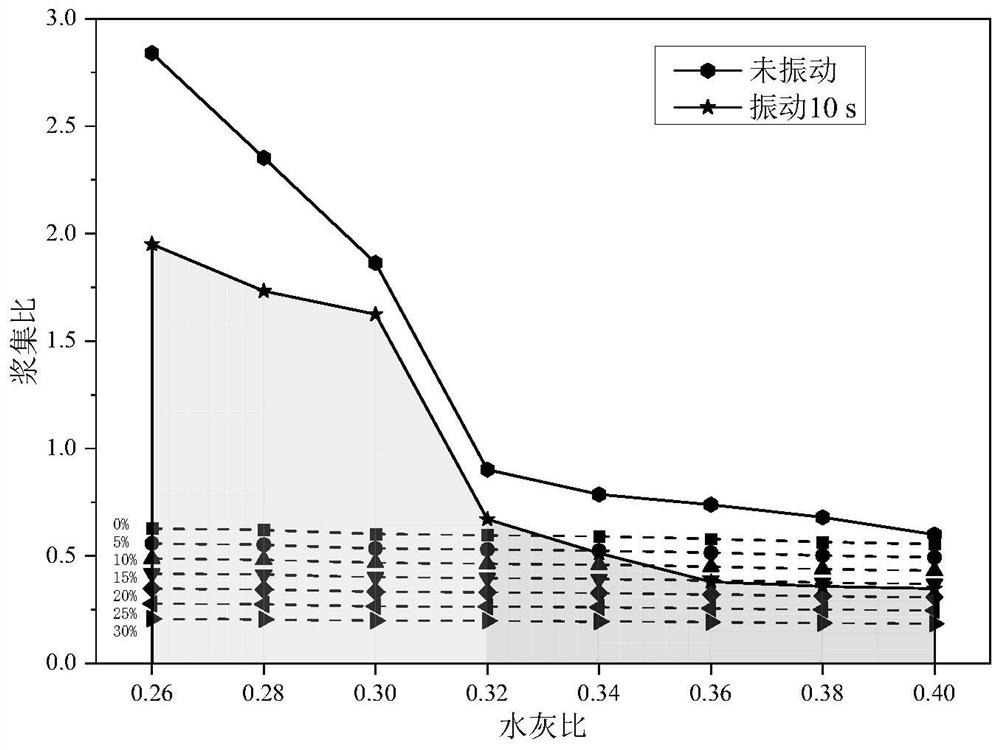

[0058] 3) Weigh the mass as m 1 Aggregate two parts, m 1 (unvibrated) = 30.4g, m 1 (...

Embodiment 2

[0067] The design method of permeable concrete mix ratio based on cement mortar density and coating performance, the specific process is as follows:

[0068] 1) with embodiment 1.

[0069] 2) Prepare cement paste, cement dosage m C =752g, the amount of silica fume m SF =48g, the amount of latex powder m L = 8g, the amount of early strength agent m E =8g, water consumption is m W = 256 g. Determine the density of the glue as ρ B =2.0907g / cm 3 . Calculation of the design glue dosage M B and design pulp set ratio R B / A :

[0070] m B =V B ·ρ B =0.2814m 3 ×2.0907g / cm 3 =588.3kg

[0071]

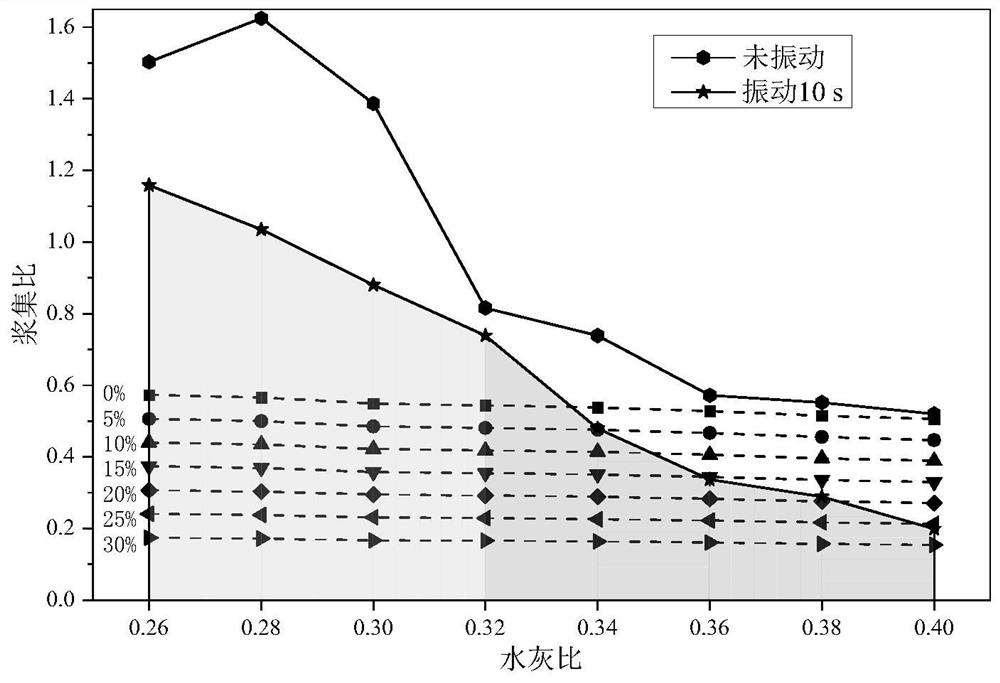

[0072] 3) Weigh the mass as m 1 Aggregate two parts, m 1 (unvibrated) = 30.0g, m 1 (Vibration)=30.4g, add 60g of freshly mixed cement mortar respectively, and mix the two evenly. Immediately put the mixture into a 2.36mm square hole sieve, and allow the mortar to flow freely (not vibrated) or flow out under vibration for 10s (tightened) from the square hole sieve within 30s...

Embodiment 3

[0084] The design method of permeable concrete mix ratio based on cement mortar density and coating performance, the specific process is as follows:

[0085] 1) with embodiment 1.

[0086] 2) Prepare cement paste, cement dosage m C =752g, the amount of silica fume m SF =48g, the amount of latex powder m L = 8g, the amount of early strength agent m E =8g, the dosage of water reducing agent is 0.64g, and the water consumption is m W = 256 g. Determine the density of the glue as ρ B =2.0234g / cm 3 . Calculation of the design glue dosage M B and design pulp set ratio R B / A :

[0087] m B =V B ·ρ B =0.2814m 3 ×2.0234g / cm 3 =569.4kg

[0088]

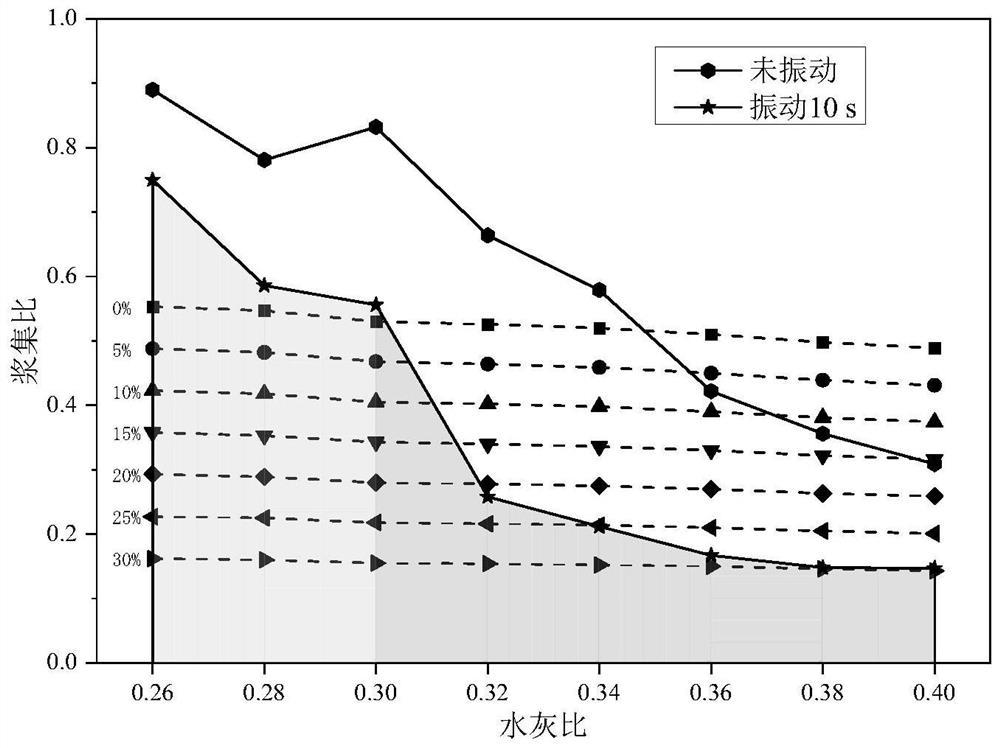

[0089] 3) Weigh the mass as m 1 Aggregate two parts, m 1 (unvibrated) = 30.1g, m 1 (Vibration)=30.2g, add 60g of freshly mixed cement mortar respectively, and mix the two evenly. Immediately put the mixture into a 2.36mm square hole sieve, and allow the mortar to flow freely (not vibrated) or flow out under vibration for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com