Acer truncatum oil emulsion and application thereof

A technology of ingot maple oil and ingot maple, which is applied in the field of medicine, can solve the problems of scarcity of raw materials and poor stability of compound medical emulsions, and achieve the effects of improving behavior, reasonable matching, and promoting digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

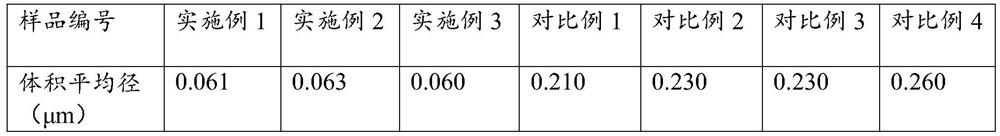

Embodiment 1

[0029] An ingot maple oil emulsion, each 1000g includes the following raw materials: 140g ingot maple oil, 12g fructooligosaccharide, 30g soybean lecithin, 20g monoglyceride, 1.2g bird's nest acid, and the balance is purified water.

[0030] Preparation:

[0031] (1) First heat 500g of purified water to 69°C, then add fructooligosaccharides, soybean lecithin and monoglyceride for stirring, 1000r / min, 20min until the mixture is uniform, and obtain liquid A;

[0032] (2) When the water temperature of liquid A cools to 39°C, add ingot maple oil for high-speed shearing and homogenization; wherein, the speed of the shearing machine is 1100r / min, and the shearing time is 10min to obtain the preliminary suspension B;

[0033] (3) Add 296.8 g of purified water to the preliminary suspension B and stir evenly, and carry out high-pressure homogeneous emulsification through a high-pressure homogenizer: the first homogenization pressure is 600 bar, and the homogenization time is 10 minutes...

Embodiment 2

[0036] An ingot maple oil emulsion comprises the following raw materials per 1000 parts by weight: 150 g of ingot maple oil, 12 g of fructooligosaccharide, and 25 g of soybean lecithin. Monoglyceride 25g, bird's nest acid 1g, and the balance is purified water.

[0037] (1) First heat 500g of purified water to 70°C, then add fructooligosaccharides, soybean lecithin and monoglyceride for stirring, 1000r / min, 25min until the mixture is uniform, and obtain liquid A;

[0038] (2) When the water temperature of liquid A cools to 40°C, add ingot maple oil for high-speed shearing and homogenization; wherein, the speed of the shearing machine is 1100r / min, and the shearing time is 20min to obtain the preliminary suspension B;

[0039] (3) Add 287g of purified water to the preliminary suspension B and stir evenly, and carry out high-pressure homogeneous emulsification by a high-pressure homogenizer: the first homogenization pressure is 600bar, and the homogenization time is 10min, and re...

Embodiment 3

[0042] An ingot maple oil emulsion, comprising the following raw materials per 1000g: 160g ingot maple oil, 10g fructooligosaccharide, 20g soybean lecithin, 30g monoglyceride, 0.8g bird's nest acid, and the balance is purified water.

[0043] (1) First heat 500g of purified water to 71°C, then add fructooligosaccharides, soybean lecithin and monoglyceride for stirring, 1100r / min, 20min until the mixture is uniform, and obtain liquid A;

[0044] (2) When the water temperature of liquid A cools to 41°C, add ingot maple oil for high-speed shearing and homogenization; wherein, the speed of the shearing machine is 1000r / min, and the shearing time is 15min to obtain the preliminary suspension B;

[0045] (3) Add 279.2g of purified water to the preliminary suspension B and stir evenly, and carry out high-pressure homogeneous emulsification through a high-pressure homogenizer: the first homogenization pressure is 600bar, the homogenization time is 20min, and repeat once; the third time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com