A lime powder screening processing system

A processing system, lime powder technology, applied in the fields of sieving, solid separation, packaging, etc., can solve the problems of increased congestion, increased processing difficulty, equipment damage, etc., and achieve the effect of reducing the amount of congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

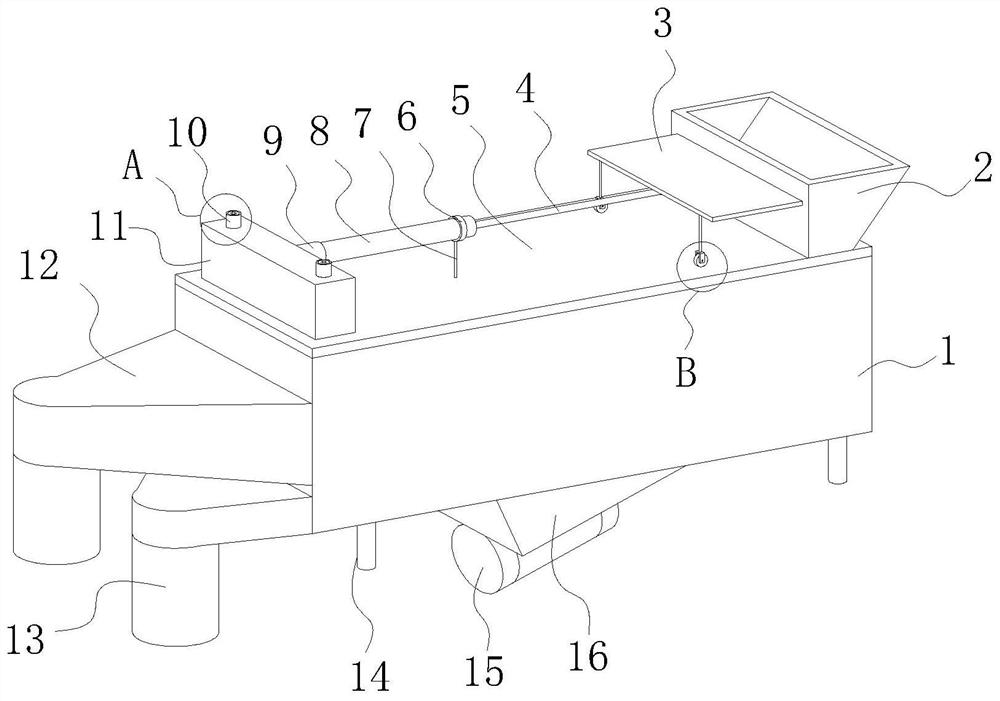

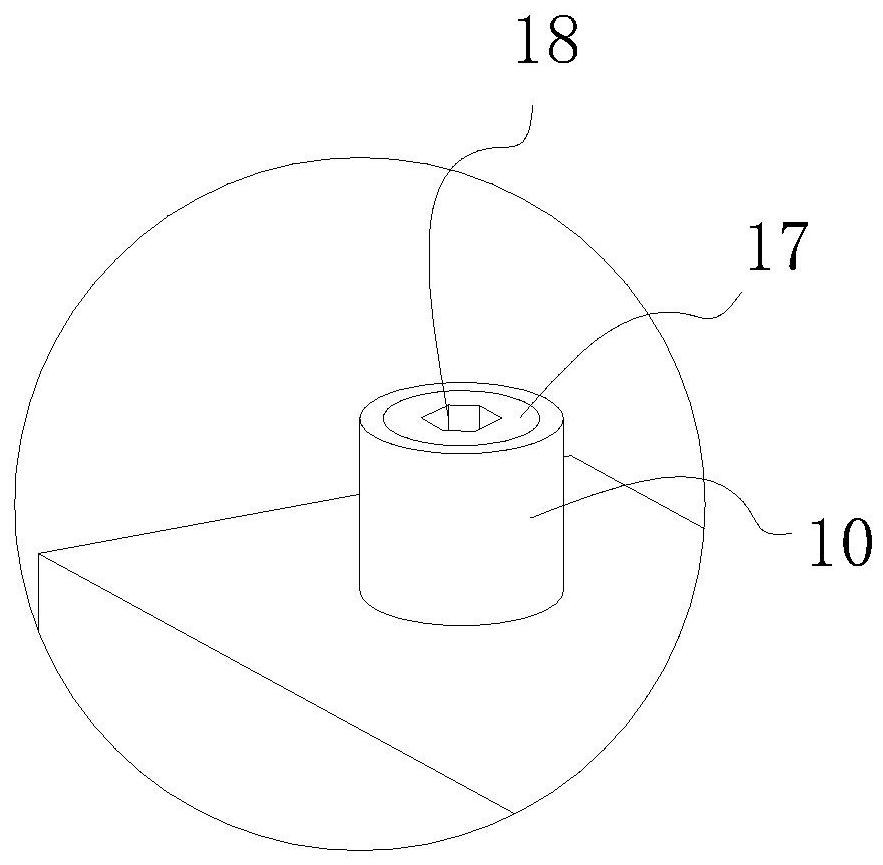

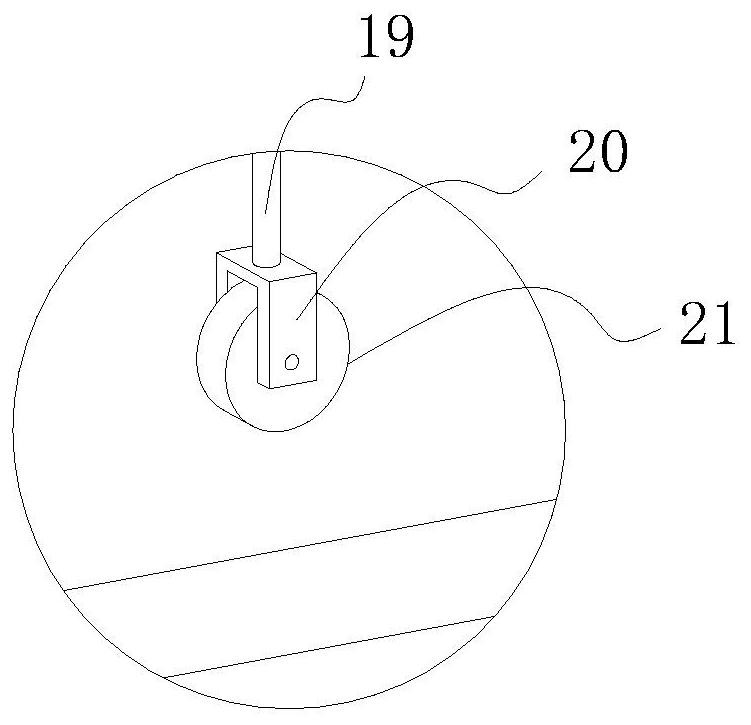

[0038] Specific implementation method: when the agglomerated lime powder accumulates at the first discharge port 12 and is blocked, along with the increase of the agglomerated lime powder at the first discharge port 12, part of the agglomerated lime powder passes through the strip The port 26 enters the rectangular sleeve 11 and forces the movable plate 23 to drive the rubber frame 24 to move upwards, so that the movable plate 23 presses the air inside the rectangular sleeve 11 into the cylinder 8, and the gas in the cylinder 8 increases to force the piston 27 To move away from the direction of the rectangular sleeve 11, the piston 27 drives the flashboard 3 to move through the movable rod 4 while the piston 27 moves, and then the flashboard 3 is inserted in the feeding hopper 2 through the slot 22, so as to realize the purpose of blocking the feeding hopper 2 in time. It is beneficial to reduce the amount of lime powder added to the sieve box 1, that is, to reduce the congesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com