Hot-gas welding method for resin-based composite and light alloy

A composite material and light alloy technology, applied in the field of thermoplastic resin matrix composite material-light alloy connection process, can solve the problem of insufficient resin filling at the joint interface, improve mechanical properties, avoid agglomeration, physical adsorption and chemical bonds. The effect of synergistic enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

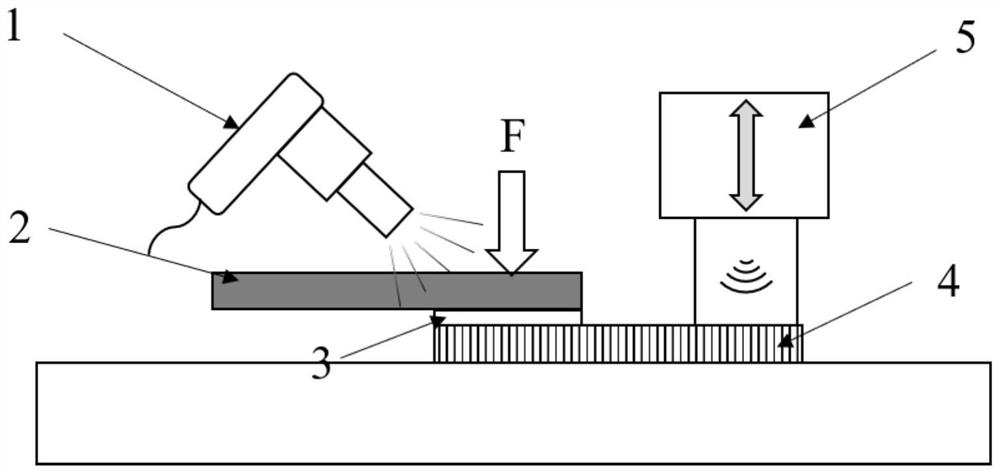

[0029] like figure 1 As shown, a PEI film 3 with a thickness of 0.20mm is placed on the overlapping area of glass fiber reinforced polyetherimide thermoplastic resin matrix composite material (GF / PEI) 4-aluminum alloy 2, and the resin matrix composite material is placed in the lower part , the light alloy is placed on the upper part, the welded joint is constructed, and the welded piece to be processed is obtained; a pressure of 0.3 MPa is applied above the overlapping area by a press, the heat gun 1 is turned on, and the position of the joint to be welded is aligned, and the temperature is adjusted so that the welded area The maximum temperature reaches 400°C, and the welding time is 120s; during the welding process, the ultrasonic transducer 5 is used to apply ultrasonic energy with a vibration frequency of 10K Hz and an amplitude of 2μm on the thermoplastic resin matrix composite material, and the introduction of ultrasonic time is 5s; after cooling , the GF / PEI thermopla...

Embodiment 2

[0031] A PEI film with a thickness of 0.25 mm was placed on the overlapping area of carbon fiber reinforced polyetherimide thermoplastic resin matrix composite (CF / PEI)-aluminum alloy, where the resin matrix composite material was placed on the lower part and the light alloy was placed on the upper part , construct the welded joint, and obtain the weldment to be processed. Use a press to apply a pressure of 0.3MPa above the overlapping area, turn on the heat gun, aim at the position of the joint to be welded, adjust the temperature so that the maximum temperature of the welding area reaches 400°C, and the welding time is 150s; during the welding process, the ultrasonic transducer is used The device applies ultrasonic energy with a vibration frequency of 10K Hz and an amplitude of 2μm to the thermoplastic resin matrix composite material, and the ultrasonic energy is introduced for 5s; after cooling, the CF / PEI thermoplastic resin matrix composite material-aluminum alloy high-e...

Embodiment 3

[0033] A PPS film with a thickness of 0.15mm was placed on the overlapping area of carbon fiber reinforced polyphenylene sulfide thermoplastic resin matrix composite (CF / PPS)-aluminum alloy, in which the resin matrix composite material was placed on the lower part and the light alloy was placed on the upper part. Construct the welded joint to obtain the weldment to be processed. Use a press to apply a pressure of 0.3MPa above the overlapping area, turn on the heat gun, aim at the position of the joint to be welded, adjust the temperature so that the maximum temperature of the welding area reaches 250°C, and the welding time is 180s; during the welding process, the ultrasonic transducer is used The device applies ultrasonic energy with a vibration frequency of 10K Hz and an amplitude of 2 μm to the thermoplastic resin matrix composite material, and the ultrasonic energy is introduced for 8s; after cooling, the CF / PPS thermoplastic resin matrix composite material-aluminum alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com