Intelligent factory sewage treatment system and treatment method thereof

A technology for sewage treatment systems and factories, applied in water/sewage treatment, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc. The effect of convenient docking, easy installation or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

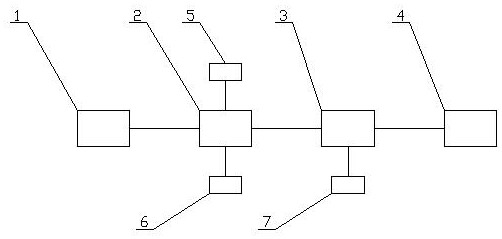

[0044] A smart factory sewage treatment system, such as Figure 1-18 As shown, it includes a collection device 1 , a sedimentation device 2 , a processing device 3 and a recycling device 4 arranged in sequence. The sedimentation device 2 is connected with a sampling device 5 and a sludge discharge device 6 , and the processing device 3 is provided with an aeration device 7 .

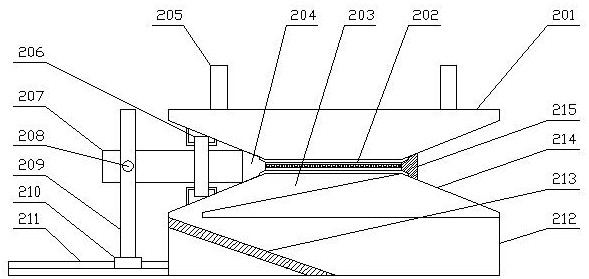

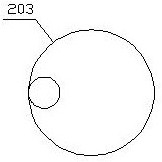

[0045] The sedimentation device 2 includes a sedimentation tank structure, which is connected to the collection device 1 through a water inlet pipe 205. One side of the sedimentation tank structure is provided with a filtering and conveying structure; the sedimentation tank structure includes an inverted cone cylindrical upper filter tank 201, and the upper sedimentation tank 201 Connected with a support structure for fixing the upper sedimentation tank 201, the support structure is the prior art, not shown in the figure, the upper filter tank 201 can be one of a cylinder, a square cylinder, and an inclin...

Embodiment 2

[0053] Such as Figure 19 , Figure 20 As shown, compared with Embodiment 1, this embodiment is provided with a pair of filter conveying structures on both sides of the sedimentation tank structure, and the two filter conveying structures are matched with the upper filter structure. A pair of bow-shaped clamping plates are arranged symmetrically at the position where the structure matches the filter conveying structure, and the others are consistent with Embodiment 1.

Embodiment 3

[0055] Such as Figure 21-23 As shown, compared with Embodiment 1, the present embodiment is provided with a reaction structure inside the reaction box 301, and the reaction structure includes a vertically arranged fixed rod 304, and the fixed rod 304 is provided with a reaction plate structure 302 in the shape of an inverted quadrangular prism. The reaction tray structure 302 is composed of four inverted trapezoidal reaction trays that are inclined downward and can be detachably connected. The top and bottom ends of the inverted trapezoidal reaction tray are consistent with the top and bottom structures of the aeration chamber in Example 1. In this embodiment, the inverted trapezoidal reaction tray is substantially equivalent to the aeration chamber structure in Example 1 and does not exist The connecting seat and others are the same as those in Example 1, the only difference lies in the structure of the reaction disc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com