Impact-resistant automobile front wall sound insulation pad and preparation method thereof

An impact-resistant and sound-insulating pad technology is applied in the field of automobile parts preparation, which can solve the problems of poor product strength, unfavorable vehicle lightweight, energy saving, and large product weight, etc., and achieve the effect of improving surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

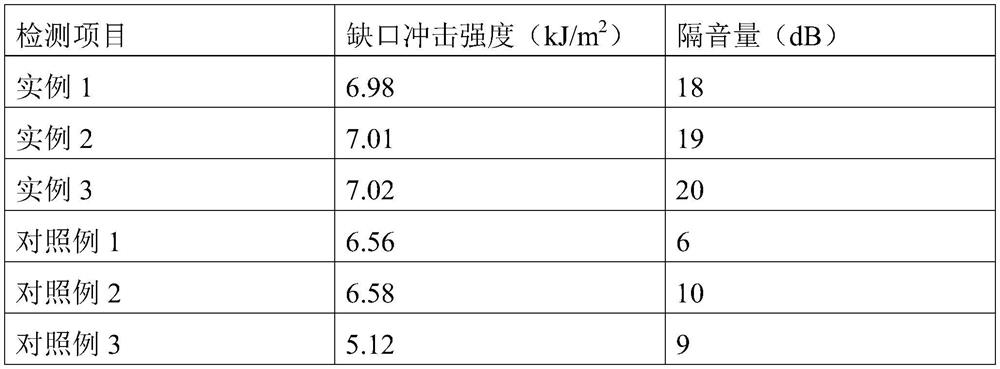

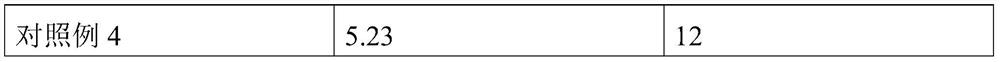

Examples

example 1

[0040] Weigh the pork bone and wash it and put it into a pulverizer to pulverize it to obtain the pulverized pork bone. The pulverized pork bone, water and protease are mixed in a mass ratio of 10:100:3 and then put into an enzymatic hydrolysis tank. Incubate the enzymolysis for 10 hours under the condition of ℃, and obtain the enzymolysis powder after the end of the enzymolysis;

[0041] Put the enzymolysis pulverized product obtained above into a carbonization furnace, heat up to 300°C under the protection of nitrogen, heat-preserve and carbonize for 3 hours, and obtain porous pig bone charcoal after carbonization;

[0042] Weigh the straw and put it into a ball mill, mill it for 1 hour, pass it through a 200-mesh sieve, collect the sieved straw powder, then mix the sieved straw powder and porous pig bone charcoal at a mass ratio of 1:2 and put it into ultrasonic vibration In the instrument, after 3 hours of ultrasonic vibration treatment at a frequency of 25kHz, the modifie...

example 2

[0047] Weigh the pig bone and wash it and put it into a pulverizer to pulverize it to obtain the pulverized pig bone. The pulverized pig bone, water and protease are mixed in a mass ratio of 10:100:3 and then put into an enzymatic hydrolysis tank. Incubate the enzymolysis for 11 hours under the condition of ℃, and obtain the enzymolysis powder after the end of the enzymolysis;

[0048] Put the enzymolysis pulverized product obtained above into a carbonization furnace, heat up to 350°C under the protection of nitrogen, heat-preserve and carbonize for 3 hours, and obtain porous pig bone charcoal after carbonization;

[0049] Weigh the straw and put it into a ball mill pulverizer, pass it through a 200-mesh sieve after ball milling for 2 hours, collect the sieved straw powder, then mix the sieved straw powder and porous pig bone charcoal according to the mass ratio of 1:2 and put it into ultrasonic vibration In the instrument, the modified porous pig bone charcoal was obtained af...

example 3

[0054] Weigh the pork bone and wash it and put it into a pulverizer to pulverize it to obtain the pulverized pork bone. The pulverized pork bone, water and protease are mixed in a mass ratio of 10:100:3 and then put into an enzymatic hydrolysis tank. Incubate the enzymatic hydrolysis for 12 hours under the condition of ℃, and obtain the enzymatic crushed product after the end of the enzymatic hydrolysis;

[0055] Put the enzymolysis pulverized product obtained above into a carbonization furnace, heat up to 400°C under the protection of nitrogen, heat-preserve and carbonize for 4 hours, and obtain porous pig bone charcoal after carbonization;

[0056] Weigh the straw and put it into a ball mill pulverizer, pass it through a 200-mesh sieve after ball milling for 2 hours, collect the sieved straw powder, then mix the sieved straw powder and porous pig bone charcoal according to the mass ratio of 1:2 and put it into ultrasonic vibration In the instrument, the modified porous pig b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com