High-heat-resistance ultralow-dielectric-constant quartz fiber-reinforced polypropylene material and preparation method thereof

A polypropylene material and quartz fiber technology, applied in the field of high heat-resistant and ultra-low dielectric quartz fiber reinforced polypropylene material and its preparation, can solve the problems of poor compatibility, affecting the thermal deformation temperature and linear expansion coefficient of polypropylene materials, etc. , to achieve the effect of low electric field loss, excellent dimensional stability, and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

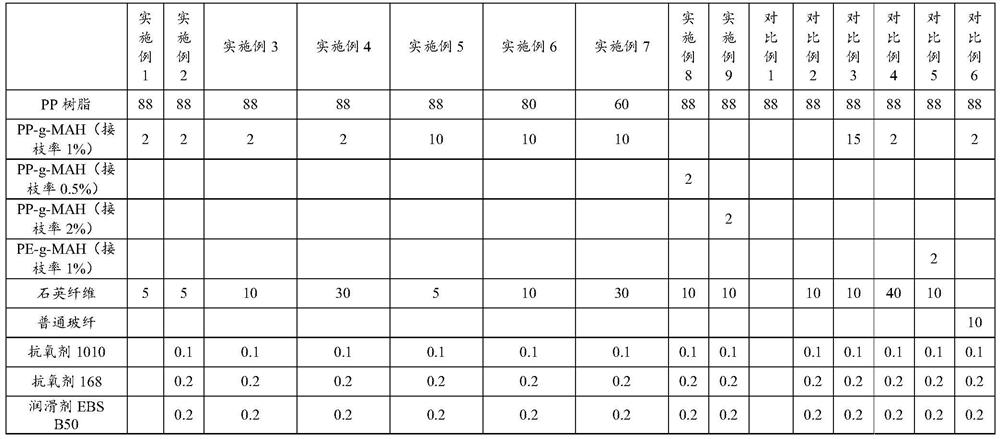

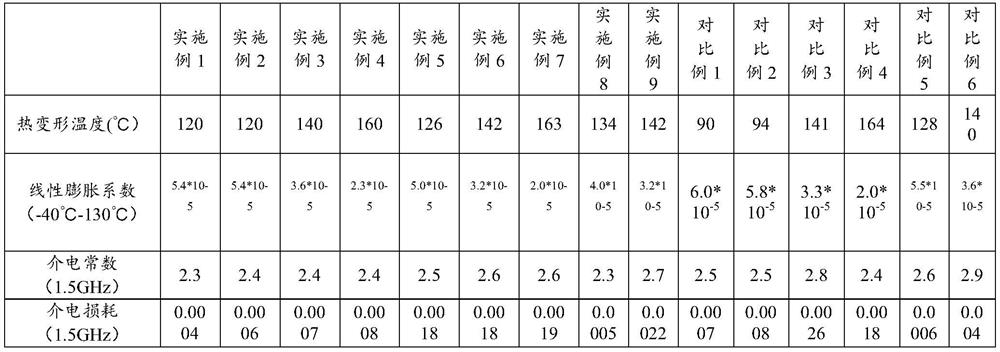

[0023] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

[0024] The raw materials of the following examples and comparative examples are described as follows:

[0025] PP resin: China Sea Shell, PP HP500N;

[0026] PP-g-MAH: maleic anhydride grafted polypropylene, grafting rate 1wt%, Nanhai Baichen PC-1;

[0027] PP-g-MAH: maleic anhydride grafted polypropylene, grafting rate 0.5wt%, self-made by Kingfa Technology, its preparation method is: add PP into twin-screw extruder, add initiator and maleic anhydride at the same time, through Initiating grafting reaction in the extruder to obtain PP-g-MAH with a grafting rate of 0.5wt%;

[0028] PP-g-MAH: maleic anhydride grafted polypropylene, grafting rate 2wt%, self-made by Kingfa Technology, its preparation method is: add PP into twin-screw extruder, add initiator and maleic anhydrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com