Cu2O single crystal nanoparticle-polymer composite film with bright structural color and preparation method thereof

A single crystal nanometer and polymer technology, applied in the field of structural color materials and new material research, to achieve a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

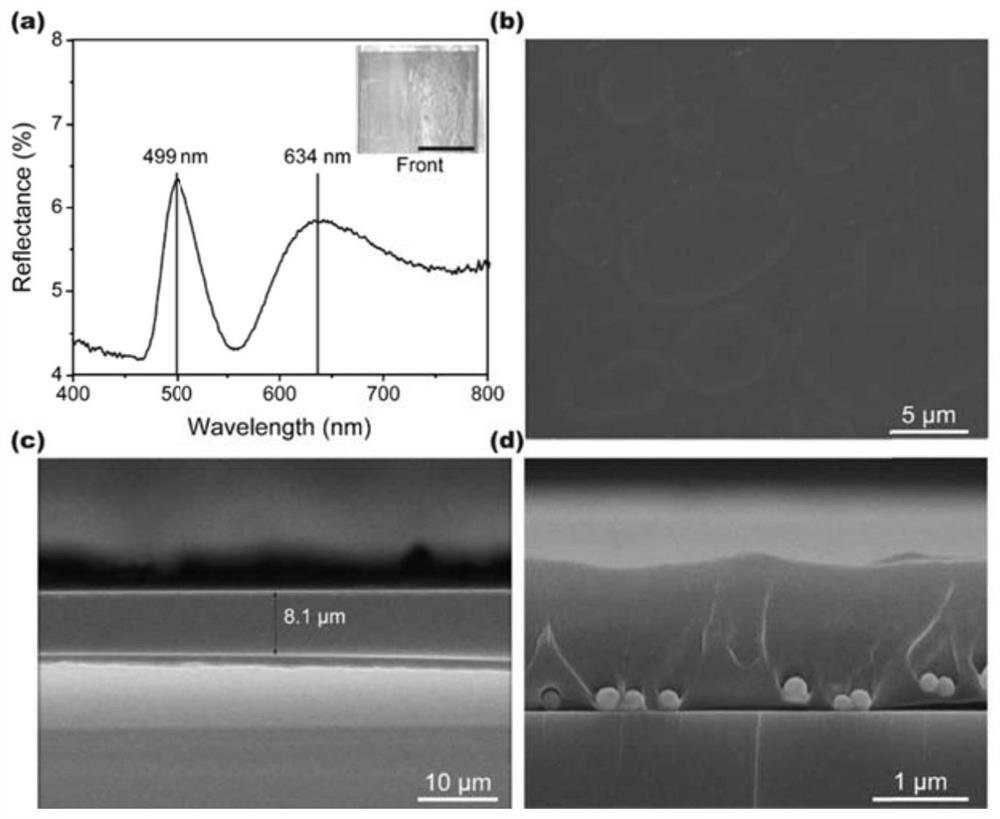

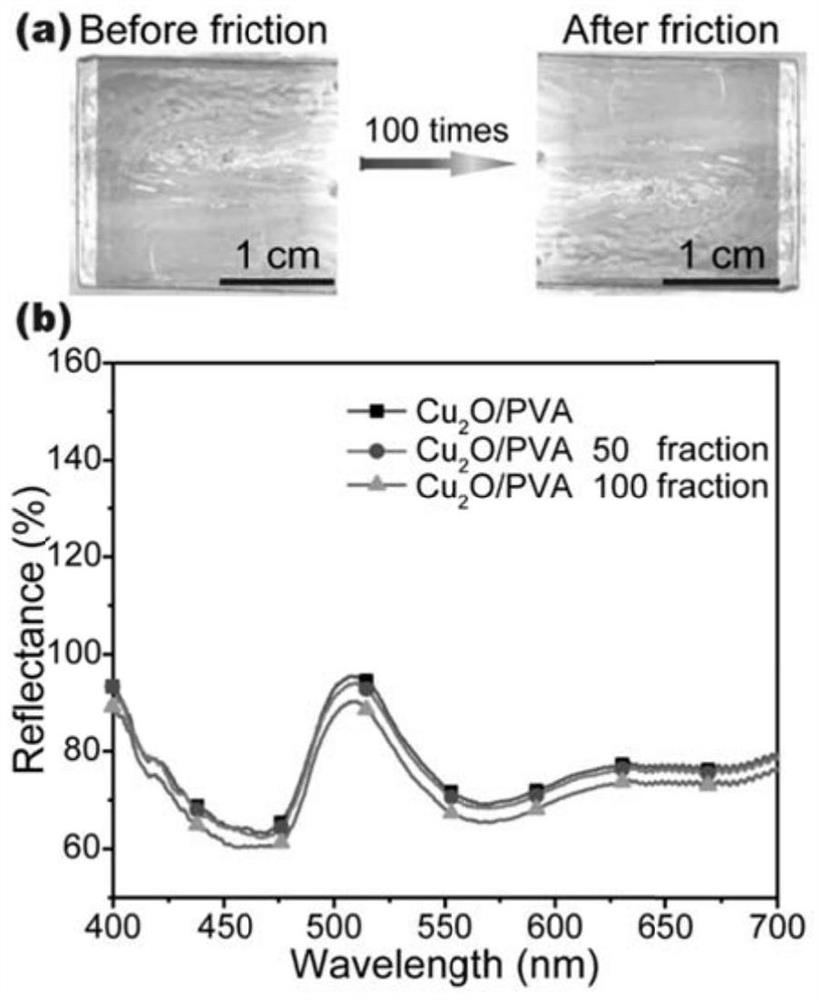

[0031] Cu 2 Preparation of O single crystal sphere / PVA composite film

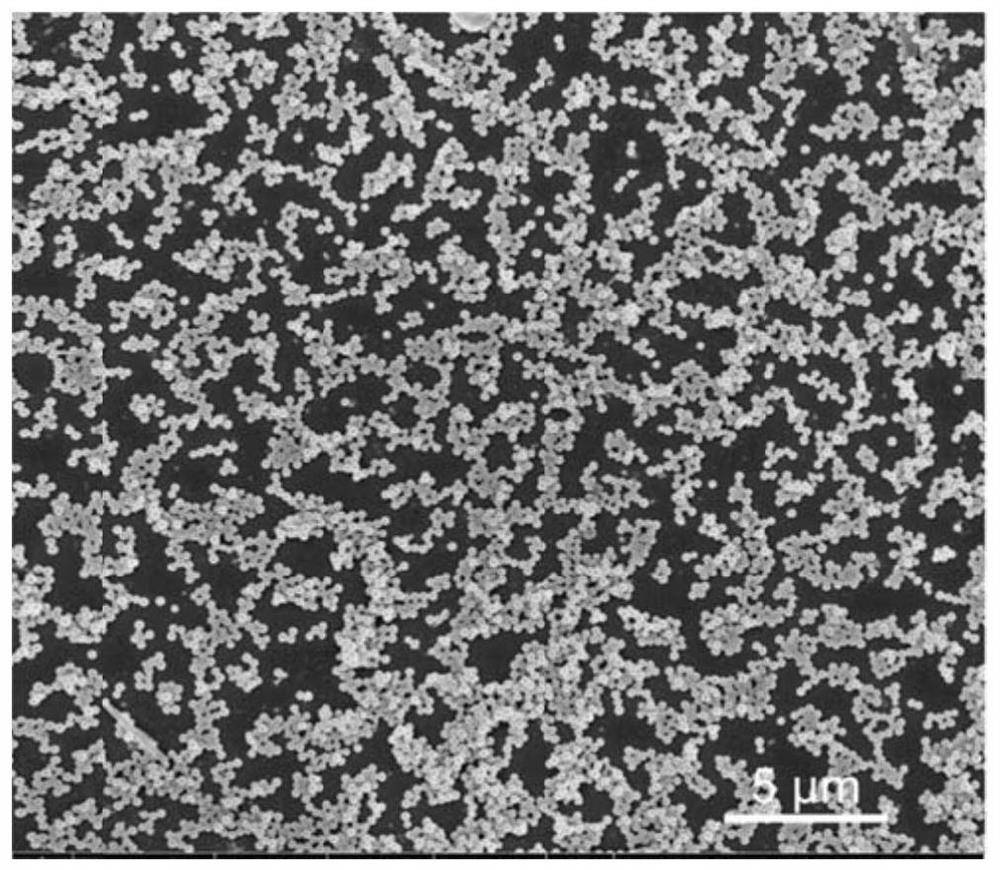

[0032] First prepare monodisperse Cu 2 O single crystal microspheres, the specific preparation method is as follows:

[0033] Weigh PVP (Mw=55000), trisodium citrate dihydrate (Na 3 Cit·2H 2 O) and copper acetate monohydrate, it is put into the beaker, then add the mixed solution of water and ethylene glycol and stir gently. Transfer the mixed solution to a three-necked flask, add NaOH solution with a concentration of 0.5M at a rate of 2mL / min to form a dark blue clear solution, and after stirring vigorously, add 0.12M NaOH at a rate of 0.4mL / s Ascorbic acid, after stirring, quickly add 0.12M ascorbic acid under stirring, react for 1 hour, centrifuge and wash three times with a mixed solution of ethanol and water, and dry for later use.

[0034] Weigh a certain amount of monodisperse Cu 2 O single crystal sphere powder, add absolute ethanol to prepare a 1wt% dispersion.

[0035]A certain amount of p...

Embodiment 2

[0039] The difference with Example 1 is that no Cu 2 O monocrystalline spheres, instead using monodisperse Cu 2 O single crystal "rounded corner" hexahedron.

[0040] Cu 2 Preparation of O single crystal "rounded corner" hexahedron / PVA composite films.

[0041] Preparation of monodisperse Cu 2 O "round corner" hexahedron, the specific preparation method is as follows:

[0042] On the basis of the method of preparing single crystal spheres, keeping the ratio of reactants and ligands unchanged, only EG and H 2 The mass ratio of O was increased to 5:10 to obtain monodisperse Cu 2 O single crystal "rounded corner" hexahedron.

[0043] Weigh a certain amount of monodisperse Cu 2 O single crystal "rounded corner" hexahedral powder, add absolute ethanol to prepare a 2wt% dispersion.

[0044] A certain amount of polyvinyl alcohol powder with a molecular weight of 77,000 was weighed, and water was added to prepare a 6wt% solution.

[0045] Will Cu 2 Ethanol dispersion of O si...

Embodiment 3

[0048] Cu 2 Preparation of O single crystal sphere / cellulose composite membrane

[0049] The difference with Example 1 is that polyvinyl alcohol is not used

[0050] Using Cu in Example 1 2 Preparation of Cu from O single crystal sphere dispersion 2 O film, with cellulose as the polymer component, was prepared into a solution with a mass fraction of 10% after adding water. Take a certain amount of cellulose solution and use a coating machine to coat Cu with a thickness of 5 mm. 2 O structural color film coating on the structural color film. After drying at 80°C for 16 hours, it was peeled off from the substrate to obtain brightly colored Cu 2 O single crystal ball / cellulose composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com