Candlelight wax and preparation method thereof

A candle light, narrow fraction technology, applied in petroleum wax refining, candles, candle ingredients and other directions, can solve the problems of harsh production process operating conditions, potential safety hazards, complex processes, etc., and achieve rich product types, stable product performance, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Fischer-Tropsch synthetic wax is hydrogenated to obtain Fischer-Tropsch refined wax, which can effectively remove olefins, oxygen-containing compounds, nitrogen, sulfur and other substances that affect product odor and color in Fischer-Tropsch synthetic wax. One method or a combination of several methods in the evaporator or vacuum rectification tower separates the effective components of candlelight wax at 300-520°C, and the separation fraction range width is between 10-100°C as required.

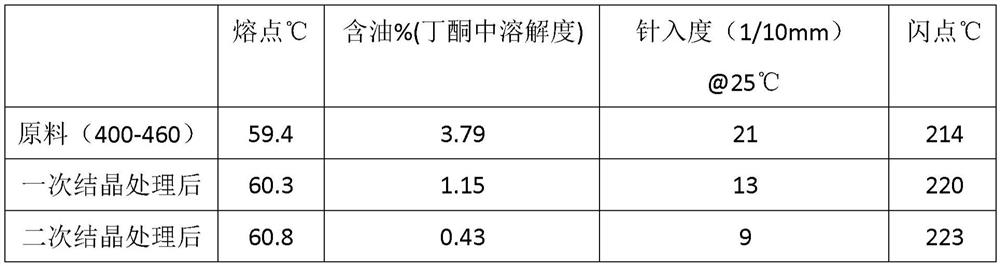

[0042] Take the treatment method of thin-film evaporator plus short-path evaporator as an example: the pressure of thin-film evaporator is controlled below 50Pa, the pressure of molecular short-path distillation is controlled below 10Pa, and the fractions shown in Table 1 are separated:

[0043] Table 1

[0044] Fraction (℃) ≤350 350-400 400-460 460-520 ≥520 Film temperature (°C) 170-180 Short-range temperature (℃) 145-160 175-190 225-240 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com