Processing system for plant essential oil preparation

A processing system and technology for plant essential oils, which are applied in the fields of essential oils/spices, grain processing, lighting and heating equipment, etc., can solve the problems of small amount of essential oils, excessive local drying, slow drying speed, etc. Speed, accelerate drying speed, avoid the effect of over-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

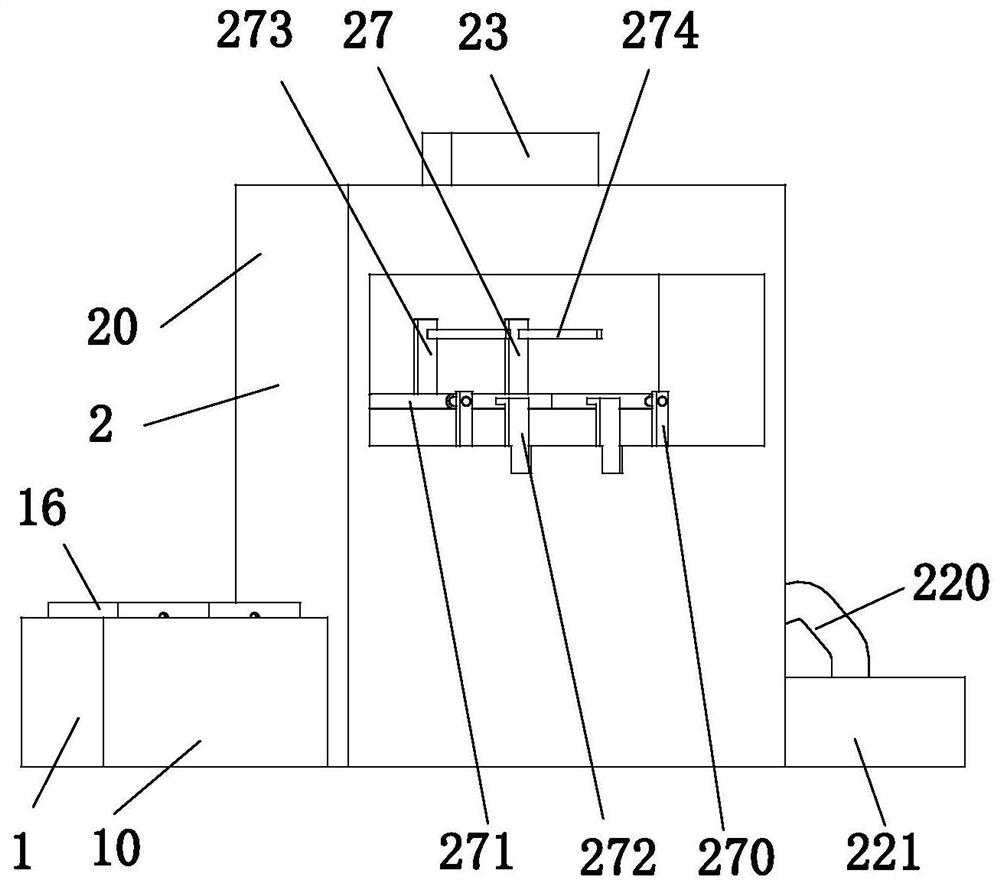

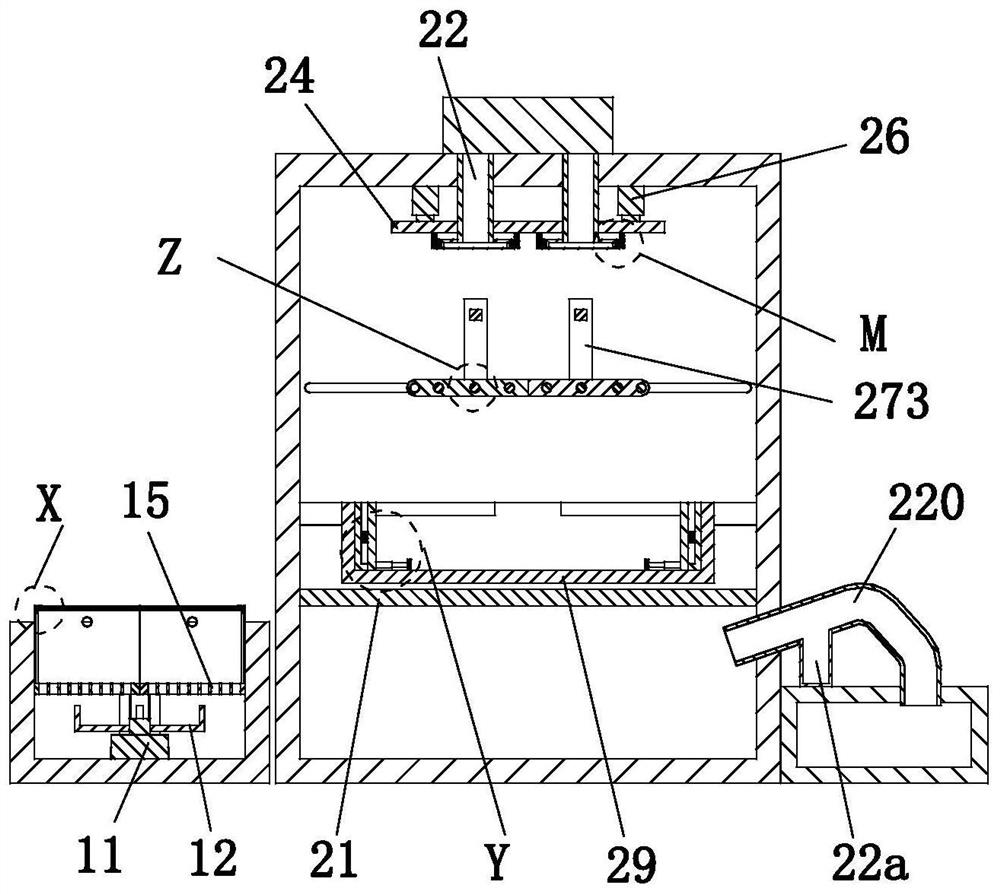

[0035] Such as Figure 1 to Figure 11 As shown, a processing system for the preparation of plant essential oils includes a cleaning mechanism 1 and a preparation mechanism 2. The lower end of the cleaning mechanism 1 is installed on the existing working ground, and the right side of the cleaning mechanism 1 is provided with the preparation mechanism 2. The lower end of the preparation mechanism 2 is connected with the existing working ground.

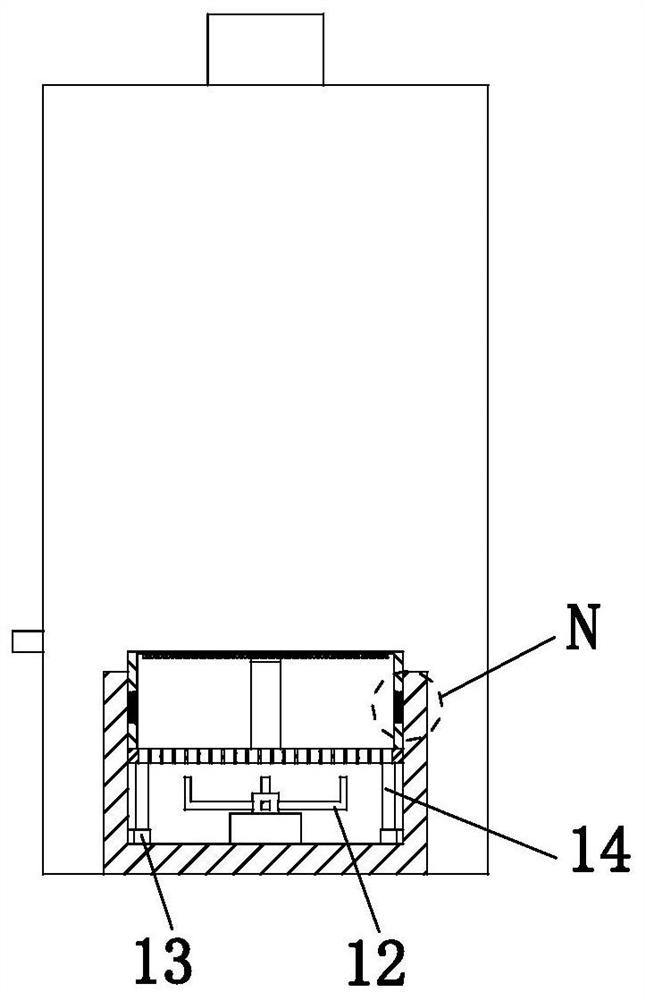

[0036] The cleaning mechanism 1 includes a cleaning tank 10, a motor 11, a stirring rod 12, a No. 1 electric slider 13, a push rod 14, a sieve plate 15, a U-shaped baffle plate 16 and a convex plate 17, and the lower end of the cleaning tank 10 is installed on On the existing working ground, a motor 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com