Plate deburring device

A technology for deburring and sheet metal, which is applied in the field of sheet metal processing, can solve the problems of affecting the texture of circular iron plates, poor soaking efficiency of circular iron plates, and affecting the deburring effect of circular iron plates, so as to improve the effect of deburring and good Effect of deburring operation, easy inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

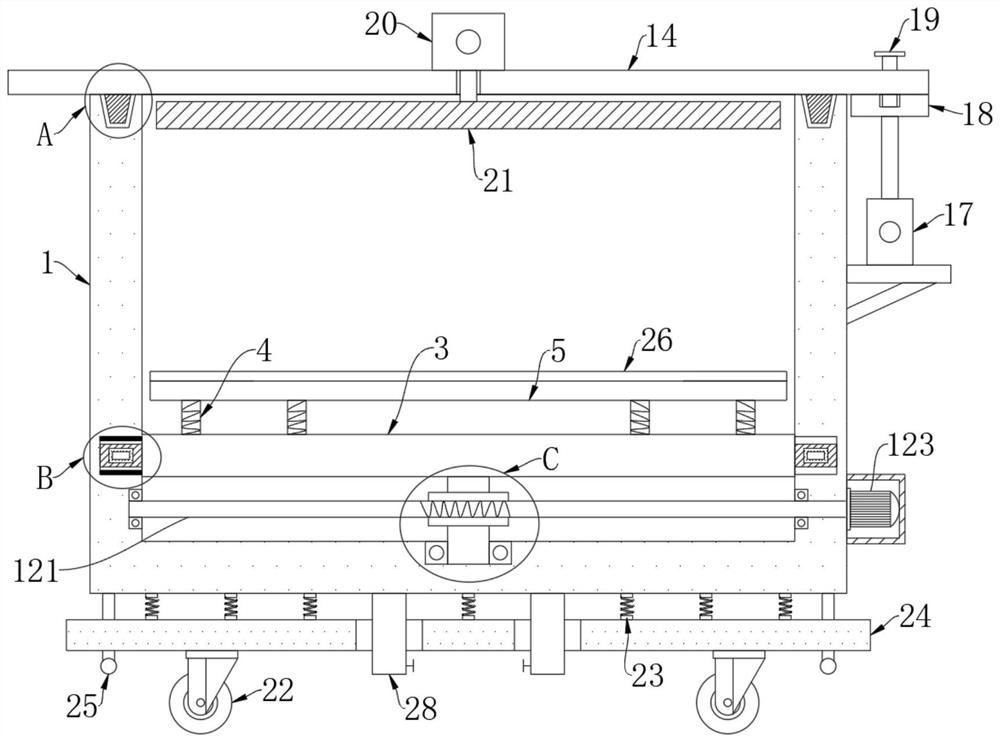

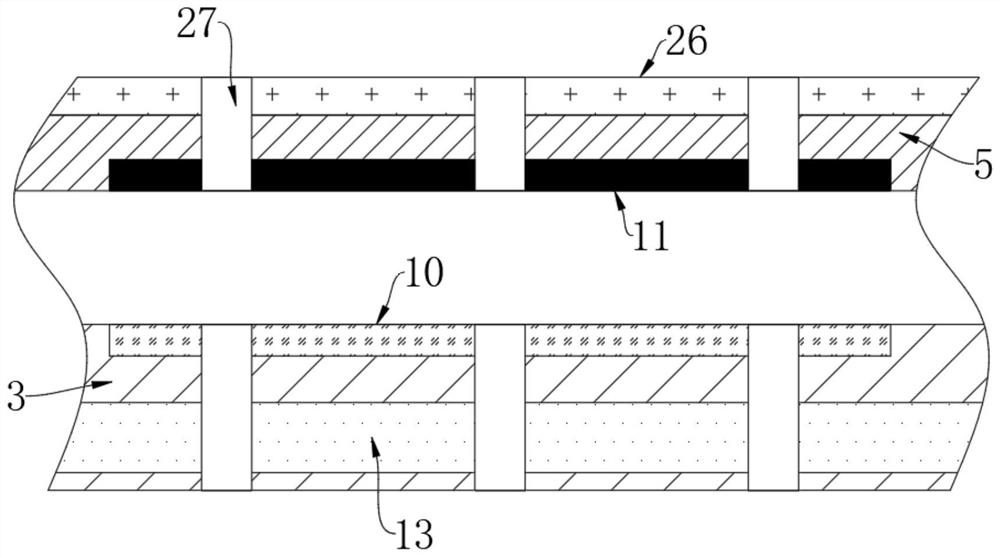

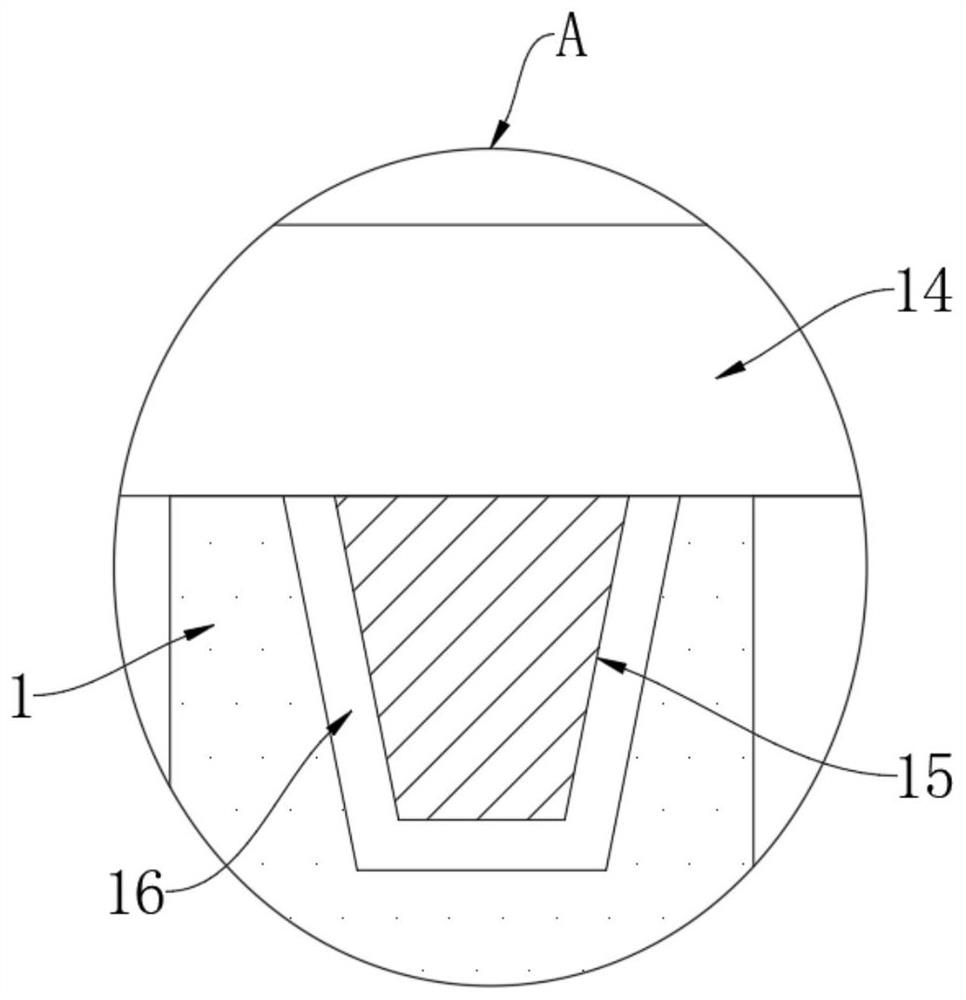

[0032] like Figure 1-5As shown, a plate deburring device includes a cartridge 1, a plurality of universal wheels 22 are connected to the side wall of the lower end of the cartridge 1, and the universal wheels 22 are self-locking, and the setting of the universal wheels 22 is convenient for the user to move Cartridge 1, the self-locking function can lock the universal wheel 22 in real time, the lower side wall of the cartridge 1 is fixedly connected with a buffer plate 24 through a plurality of damping springs 23, and the plurality of universal wheels 22 are fixedly connected to the buffer plate 24 Above, the cooperation of the damping spring 23 and the buffer plate 24 can buffer the vibration generated during the movement of the cartridge 1. The lower end side wall of the cartridge 1 is fixedly connected with a plurality of sliding rods 25, and the sliding rods 25 and the buffer plate 24 slide Connection, the setting of the slide bar 25 can limit the position of the cartridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com