Superconducting magnet connecting device and superconducting electric magnetic levitation vehicle track system

A technology of superconducting magnets and connecting devices, applied in electric vehicles, rails, vehicle parts, etc., can solve the problems of unfavorable magnetic levitation vehicle dynamic performance comfort, unable to support superconducting magnets stably and safely, and unable to elastically hang superconducting magnets and other problems, to achieve the effect of reasonable and ingenious structural design, reducing rigidity requirements and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

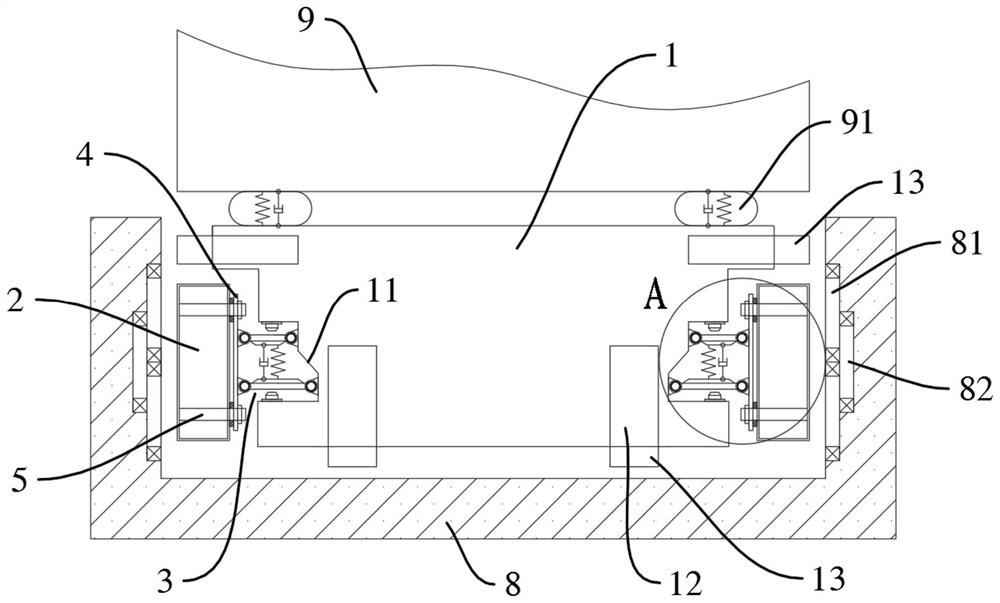

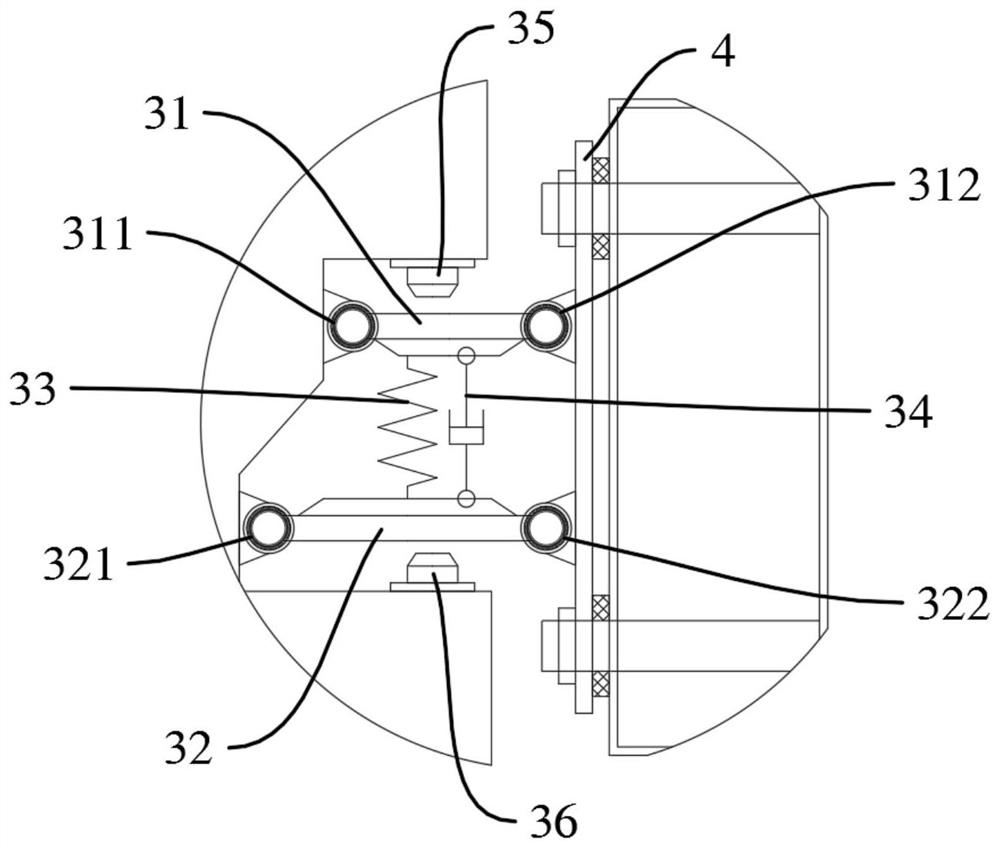

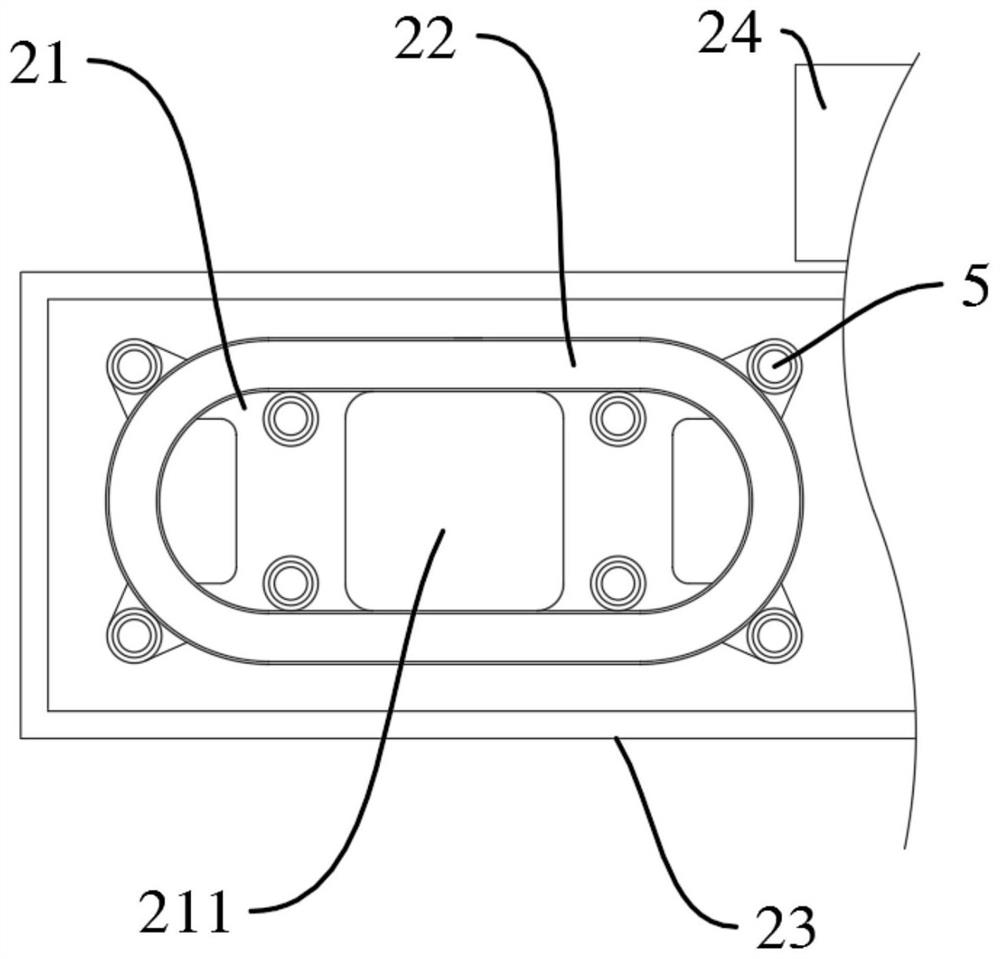

[0028] Example 1, see Figure 1 to Figure 3 , the embodiment of the present invention provides a superconducting magnet connection device, which is suitable for the connection between the suspension frame 1 and the superconducting magnet 2, including: a cavity 11, which is arranged on the suspension frame 1; an adiabatic support mechanism 21, which is placed In the superconducting magnet 2, it is used to connect and fix the inner Dewar 22 of the superconducting magnet 2; the elastic support mechanism 3 is arranged in the cavity 11, and is used to absorb the levitation frame 1 through the cavity. 11 to apply the first resultant force, and output the second resultant force after the first resultant force is damped; the force transfer member 4 is arranged between the superconducting magnet 2 and the suspension frame 1, and is connected with the elastic The support mechanism 3 is connected to transfer the second resultant force output by the elastic support mechanism 3; several fo...

Embodiment 2

[0060] Embodiment 2, with reference to Figure 1 to Figure 4 , on the basis of Embodiment 1, the elastic support part is replaced by: comprising a second damping positioning spring 61, placed between the upper wall surface of the cavity 11 and the upper cross arm 31, and with the The upper wall surface of the cavity 11 and the upper cross arm 31 are connected; the second shock absorber 62 is placed between the upper wall surface of the cavity 11 and the upper cross arm 31 , and is connected with the cavity 11 The upper wall is connected with the upper cross arm 31 ; the second low speed support spring 63 is provided on the lower wall of the cavity 11 corresponding to the lower cross arm 32 .

[0061] Specifically, the upper cross arm 31 is pushed down by the second damping positioning spring 61, and the upper cross arm 31 drives the superconducting magnet 2 to move down until the lower cross arm 32 is supported by the second low-speed support spring 63. In this state, the dow...

Embodiment 3

[0063] Embodiment 3, with reference to Figure 1 to Figure 5 , on the basis of Embodiment 1, the elastic support part is replaced by: including a third damping positioning spring 71, placed between the upper end surface of the force transfer member 4 and the suspension frame 1, and with the The upper end surface of the force transfer member 4 and the suspension frame 1 are connected; the third shock absorber 72 is placed between the upper wall surface of the cavity 11 and the upper cross arm 31, and is connected to the cavity The upper wall surface of 11 and the upper cross arm 31 are connected; the third low-speed support spring 73 is provided on the lower wall surface of the cavity 11 corresponding to the lower cross arm 32 .

[0064] Specifically, the force transfer member 4 is pushed down by the third shock-absorbing positioning spring 71, and the force transfer member 4 drives the superconducting magnet 2, the upper cross arm 31, and the lower cross arm 32 to move down un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com