A kind of automobile waste heat recovery evaporator

A waste heat recovery and evaporator technology, applied in evaporator/condenser, steam generation, engine components, etc., can solve the problems of poor heat transfer efficiency, pressure resistance and shock resistance, and achieve good mechanical properties, reduced pressure loss, and good durability The effect of compression and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

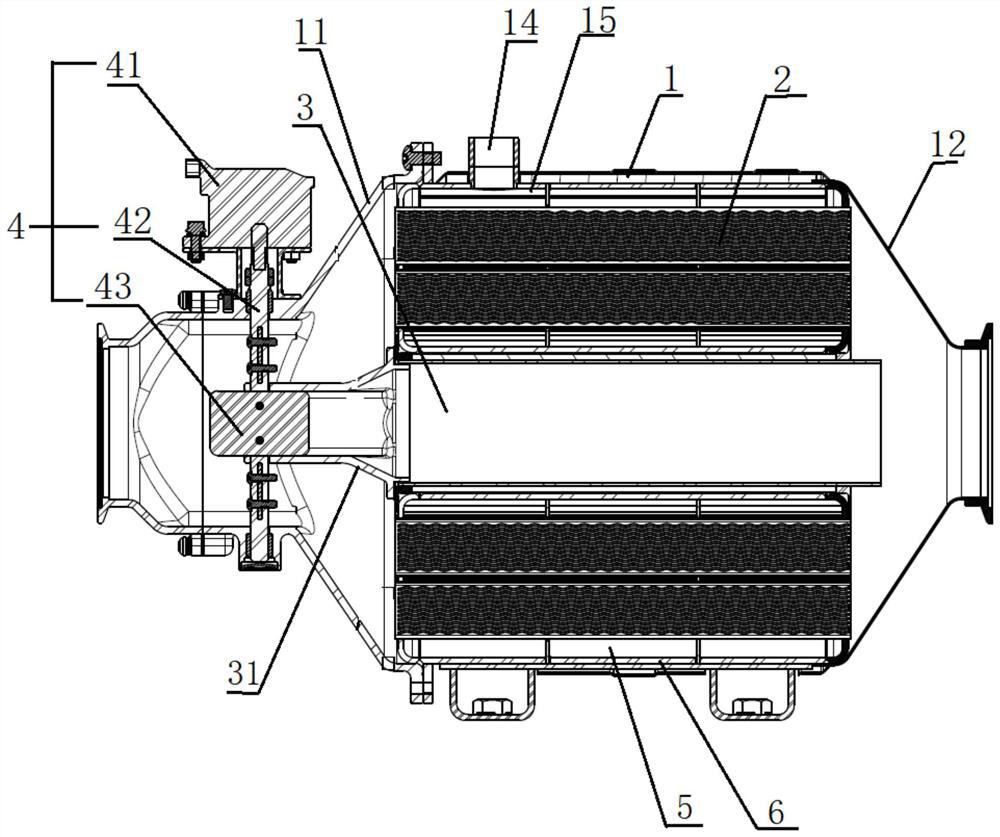

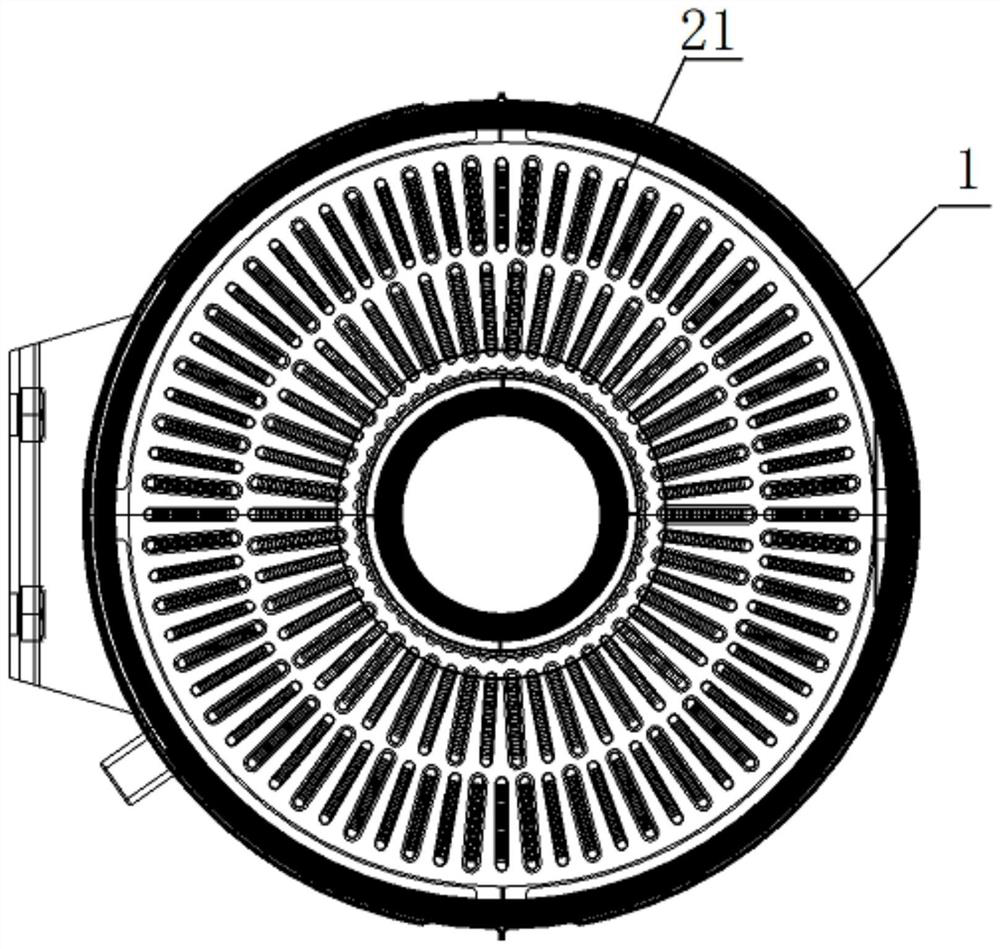

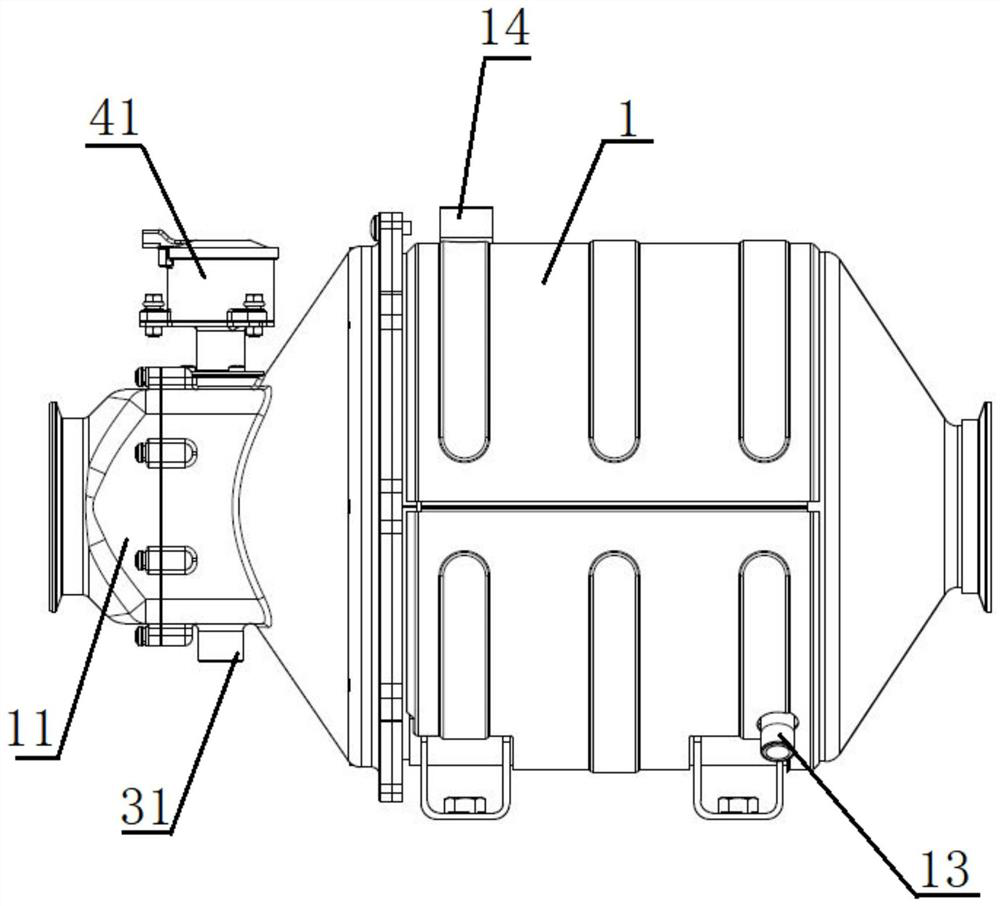

[0034] like figure 1 and figure 2 As shown, the embodiment of the present invention provides an automobile waste heat recovery evaporator, including a main casing 1, a heat exchanger 2, a bypass pipe 3 and a bypass valve 4, and the specific settings are as follows:

[0035] The main casing 1 has a cylindrical structure with open ends at both ends. The outer wall of the bottom of the main casing 1 is provided with a fixing device. The fixing device can be selected from the existing conventional fixing methods, such as hanging and horizontal installation methods. An intake diffuser 11 is installed on one end of the main casing 1, and an intake port is formed on the intake diffuser 11, and an exhaust gas collector 12 is installed on the other end of the main casing 1, and the exhaust gas collector 12 An exhaust port is formed on it to facilitate the flow of exhaust gas. The heat exchanger 2 is installed in the main shell 1, and is fitted and assembled with the main shell 1. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com