Secondary air closed-loop optimization control system based on air register resistance coefficient

A technology of resistance coefficient and optimal control, applied in the control system, control combustion, steam generation device, etc., can solve the problems such as the inability to ensure efficient and clean boilers in real time, and the difficulty of automatic adjustment of secondary air distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

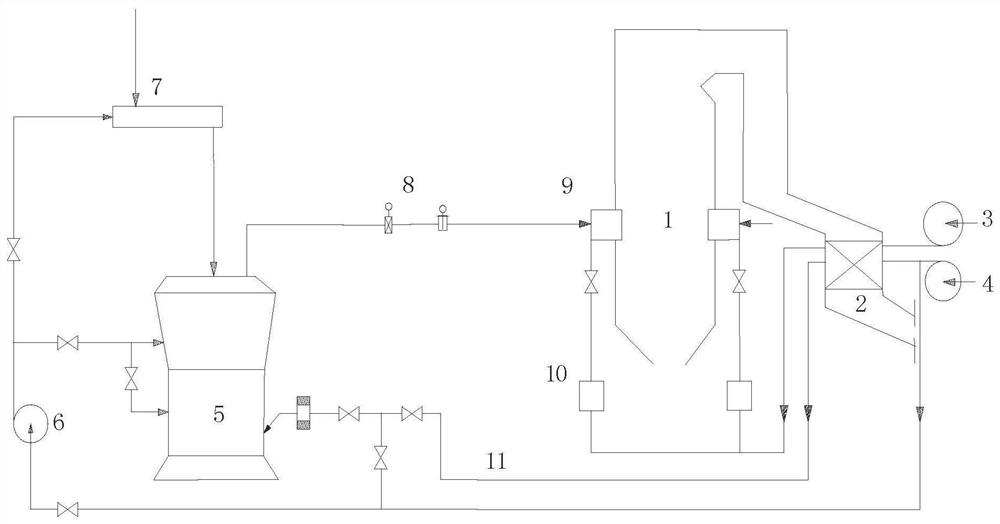

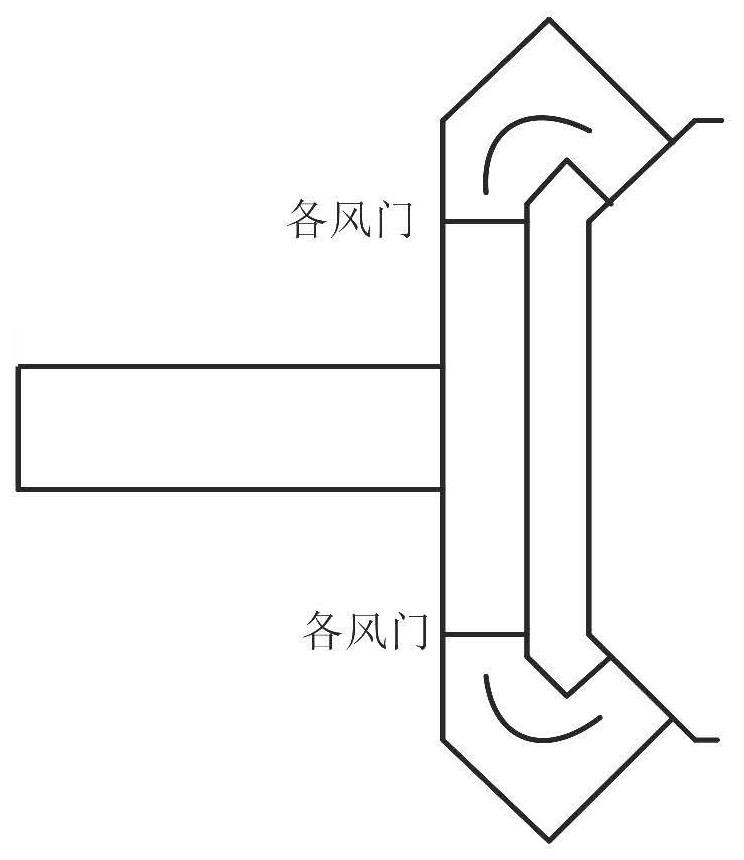

[0030] ginseng figure 1 As shown, taking the combustion system of a four-corner tangential pulverized coal boiler as an example, the entire boiler combustion system consists of a body 1, an air preheater 2, a primary fan 3, a blower 4, a medium-speed coal mill 5, a sealing fan 6, and a coal feeder 7 , Pulverized coal pipeline 8, burner 9, large air box 10 and primary air pipeline 11 are formed. The primary air generated by the primary fan 3 is heated by the air preheater 2 and then enters the medium-speed coal mill 5 through the primary air pipe 11, carries pulverized coal through the pulverized coal pipe 8, and enters the furnace through the burner 9. The secondary air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com