Chemical fiber drying device

A chemical fiber and drying device technology, which is applied in the direction of heating device, drying solid materials, dry cargo handling, etc., can solve the problems of low drying efficiency, poor drying effect, complex structure of air dryer, etc., achieve high drying efficiency and prolong the residence time , good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

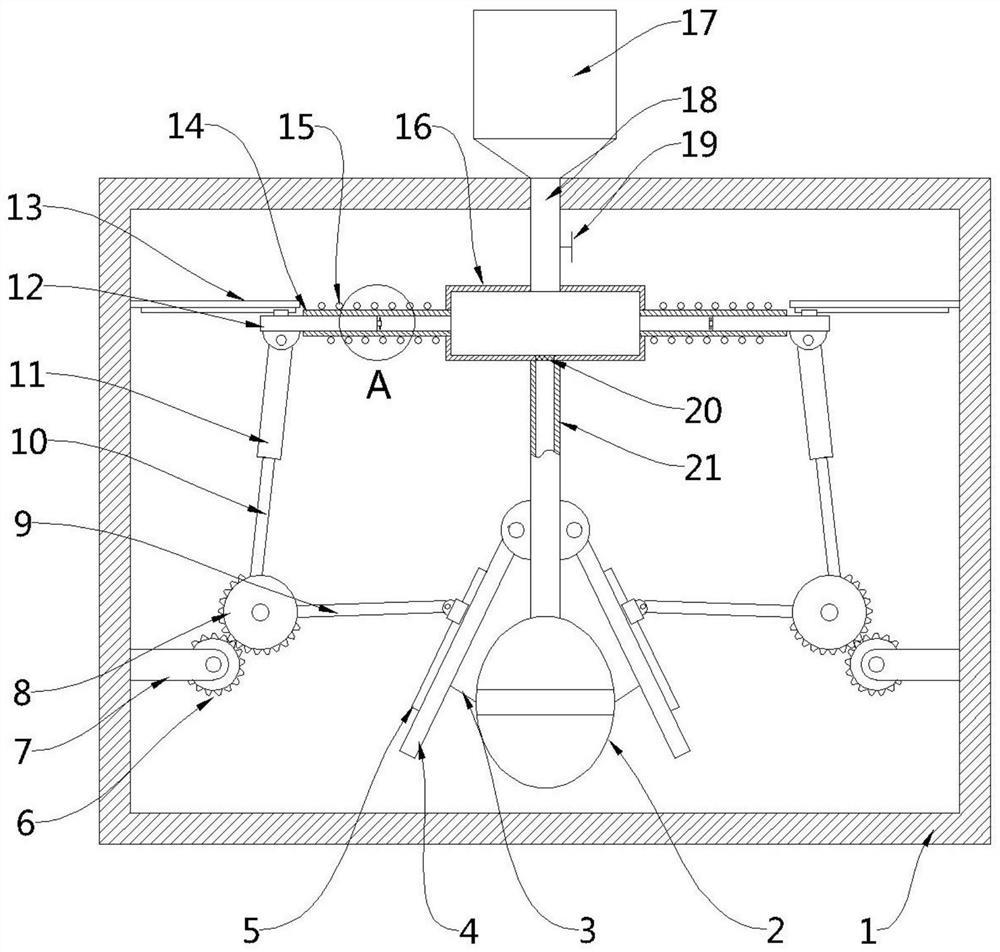

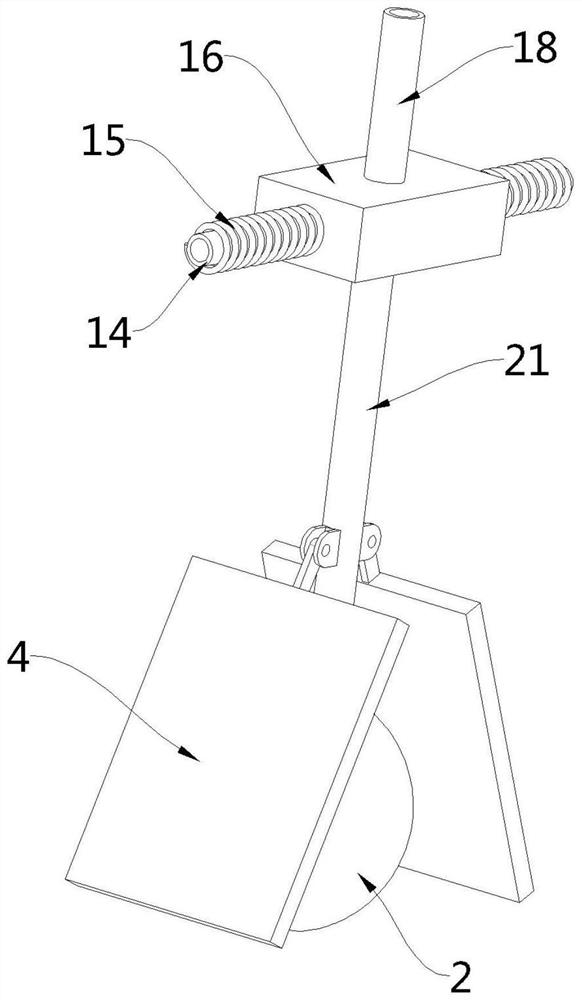

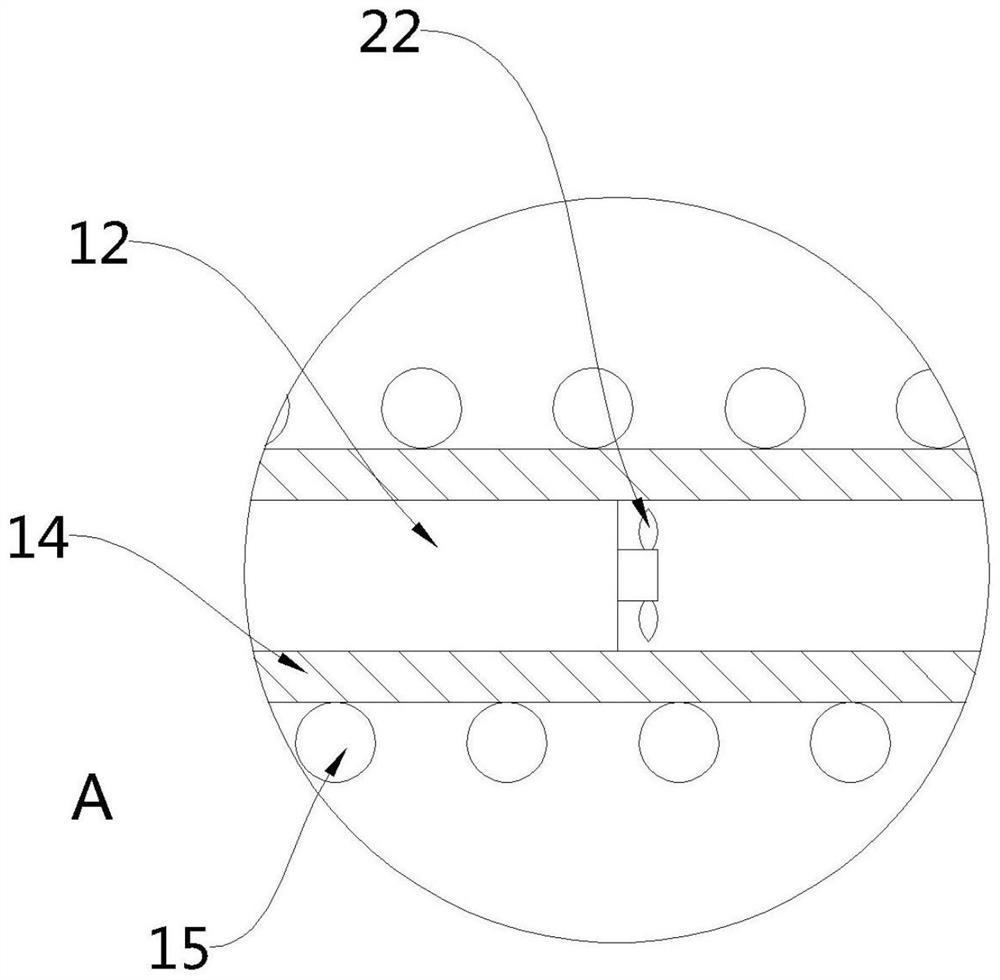

[0024] see Figure 1-3 , the present embodiment provides a chemical fiber drying device, comprising a box 1, a chemical fiber storage assembly is arranged on the upper part of the box 1, a heating assembly is arranged inside the box 1 and is used to suck chemical fibers into the heating The suction assembly inside the assembly, specifically, the material storage assembly includes a storage tank 17 and a feeding tube 18 fixedly arranged at the bottom of the storage tank 17, and a one-way valve 19 is arranged on the feeding tube 18 The heating assembly includes a storage tank 16 fixedly installed at the bottom of the discharge pipe 18, a number of discharge pipes 14 connected to the side walls of the storage tank 16 and a heating device installed on the outer wall of the discharge pipe 14 Assembly 15, the end of the discharge pipe 14 is movably inserted with a blocking rod 12, and one end of the blocking rod 12 located inside the discharge pipe 14 is equipped with an impeller 22...

Embodiment 2

[0033] see figure 1, a chemical fiber drying device. Compared with Embodiment 1, this embodiment is provided with a partition 20 at the connection between the air inlet pipe 21 and the storage box 16. Through the setting of the partition 20, the chemical fiber can be prevented from It is sucked into the inside of the feeding pipe 21, causing the chemical fibers to fail to enter the discharge pipe 14 smoothly, thereby affecting the normal drying of the chemical fibers.

[0034] In the embodiment of the present invention, the chemical fiber is continuously sucked into the storage box 16 through the material suction assembly, and the chemical fiber is transported from the storage box 16 to the discharge pipe 14, and the heating assembly 15 is used to heat and dry the chemical fiber from the discharge pipe 14. The end of the material pipe 14 is discharged. By inserting the plugging rod 12 at the end of the material discharge pipe 14, the residence time of the chemical fiber in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com