New energy automobile motor rotor multi-station intelligent detection line

A new energy vehicle, motor rotor technology, applied in the direction of electronic circuit testing, etc., can solve the problems of insufficient product positioning accuracy, scattered production layout, high degree of manual intervention, etc., to ensure product testing efficiency, save space resources, and have broad prospects overall Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

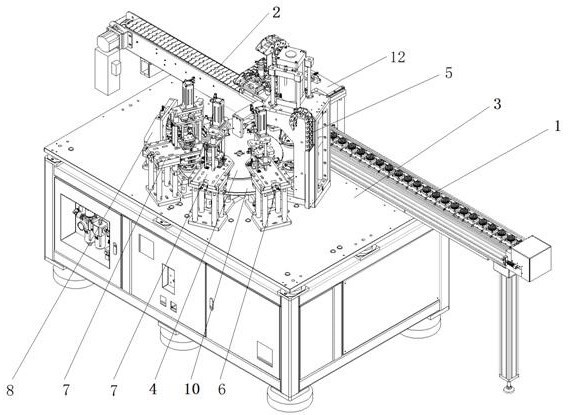

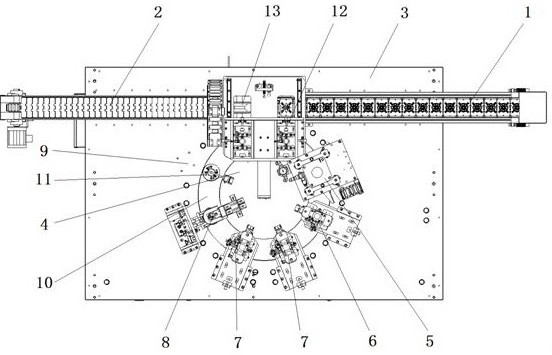

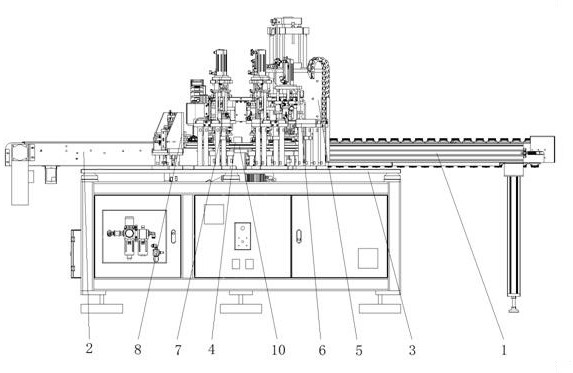

[0027] Such as Figure 1~Figure 3 As shown, the present invention discloses a multi-station intelligent detection line for the automatic detection of the inner rotor products of the new energy vehicle motor and the permanent magnet synchronous motor, and the specific scheme is as follows.

[0028] A new energy automobile motor rotor multi-station intelligent detection line, corresponding to the rotor product feeding conveying line 1 and the rotor product unloading conveying line 2, including the rotor product feeding conveying line 1 and the rotor product The loading and unloading clamping mechanism 12 between the blanking conveying line 2; also includes a plurality of functional mechanisms fixedly connected to the upper end surface of the equipment substrate 3, and a plurality of said functional mechanisms include a mounting bracket for detecting the height of the rotor product. Pressure measuring mechanism 5. Inner diameter through-gage detection mechanism for detecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com