High-speed switch valve simulation sound field modeling method coupling high-frequency collision and fluid impact

A technology of high-speed switching valves and modeling methods, which is applied in the directions of instruments, design optimization/simulation, calculation, etc., can solve the lack of modeling methods, the lack of high-frequency collision excitation source modeling methods, and the lack of fluid shock excitation source construction. model method etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

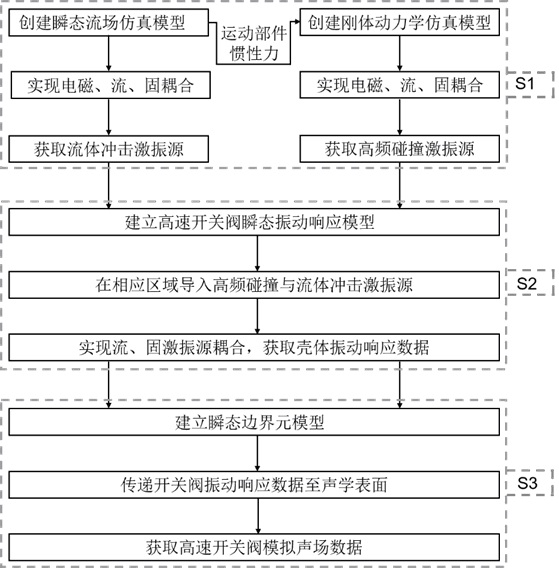

[0074] Such as figure 1 As shown, the high-speed switching valve simulation sound field modeling method coupled with high-frequency collision and fluid impact in this embodiment includes the following steps:

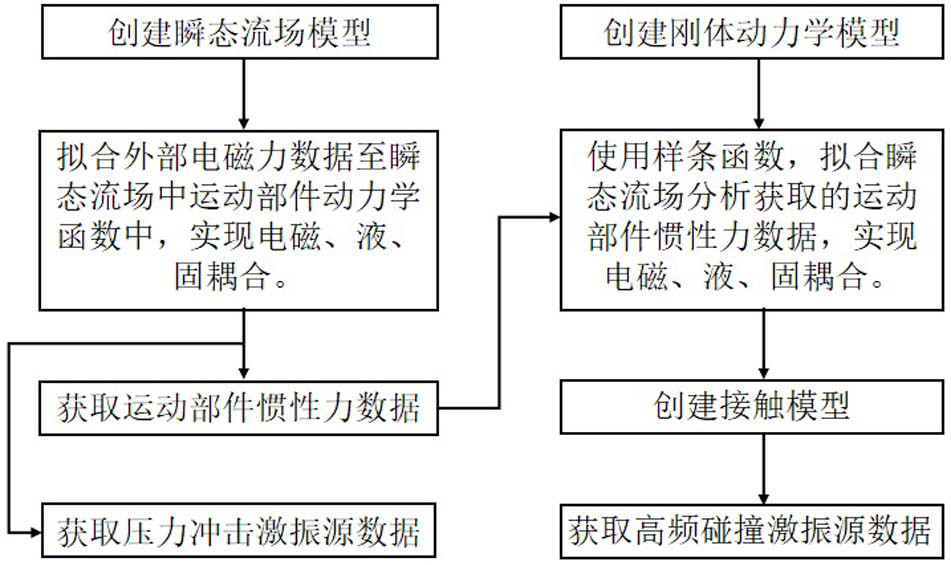

[0075] Step S1: First establish a transient flow field simulation model to obtain the fluid shock excitation source on the inner wall of the valve; then establish a rigid body dynamics simulation model and import the moving parts such as valve core and moving armature obtained in the transient flow field simulation model Inertial force data, to obtain high-frequency collision excitation source, the simulation steps are as follows figure 2 As shown, the specific process is:

[0076] Use SOLIDWORKS to establish a three-dimensional geometric model of the switch valve, import the model into Workbench Geometry, process the model with the help of the DesignModeler-Tools-Fill module, and export the flow field model;

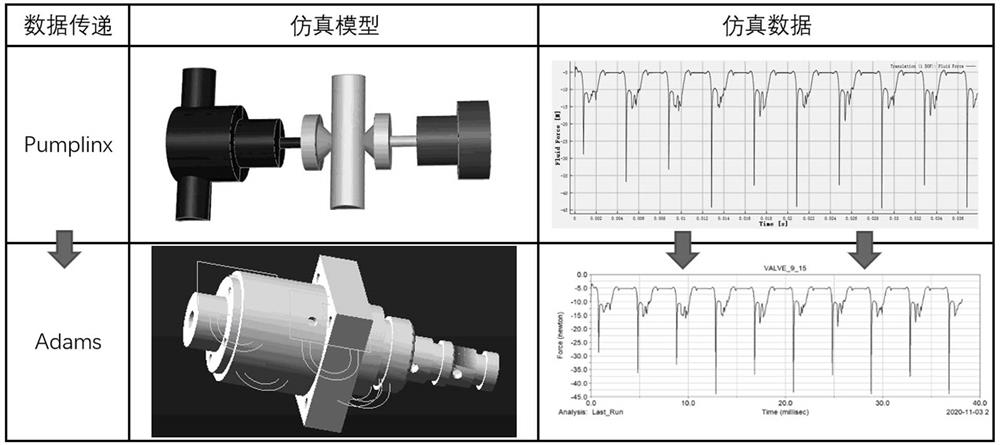

[0077] Import the flow field model into the Pumplinx simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com