Electrostatic motor based on electret film

A technology of electrostatic motors and electrets, applied in electrostatic motors, electrostatic generators/motors, generators/motors, etc., can solve problems such as difficult to guarantee stability, high driving voltage requirements, and sensitive environmental factors, etc. The effect of small motor size, avoiding heat generation, and facilitating miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

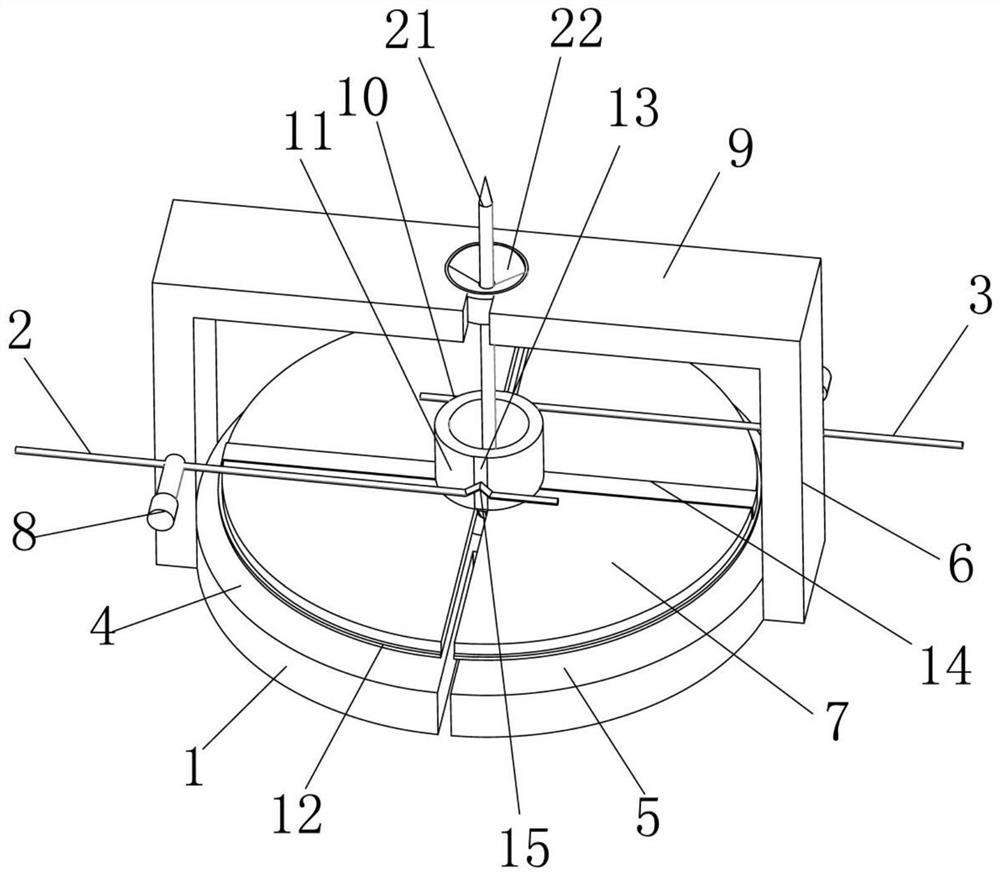

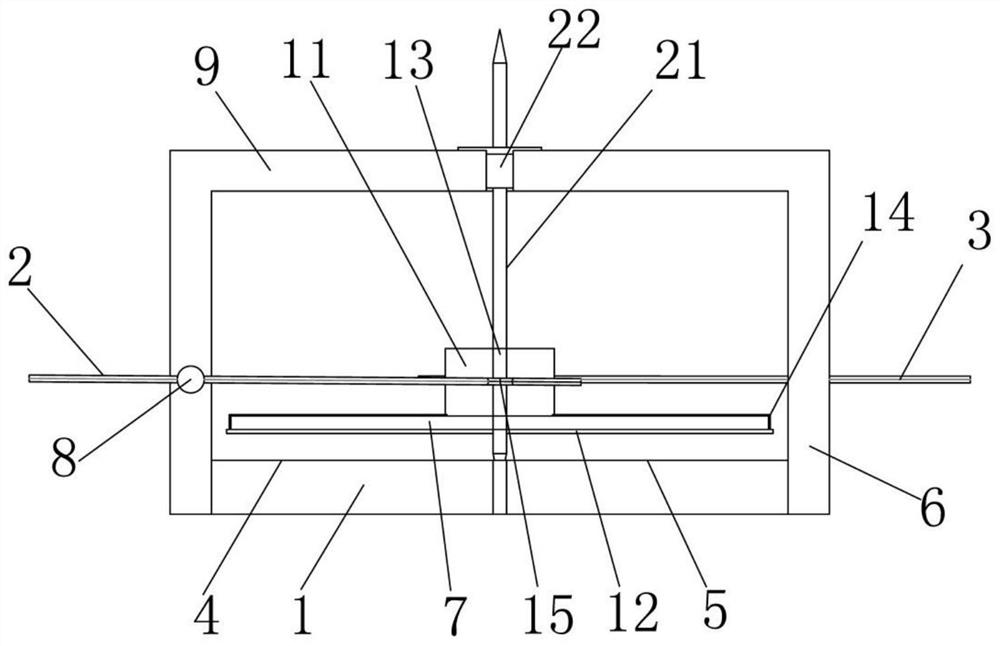

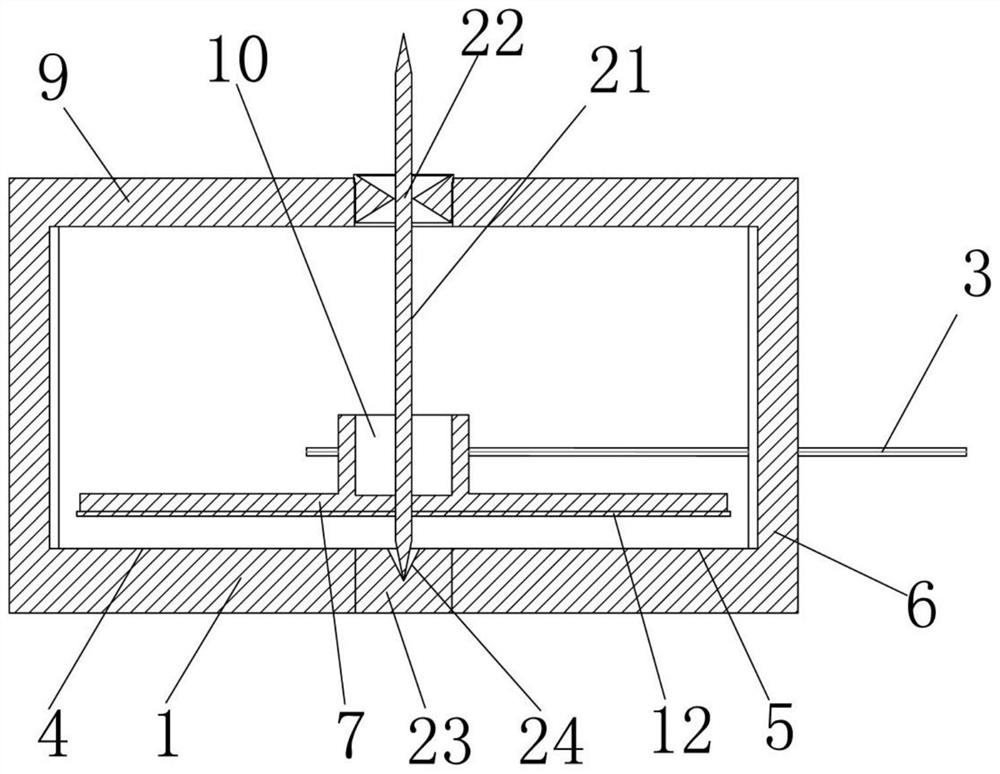

[0032] Refer to attached figure 1 and 2 As shown, the present invention relates to an electrostatic motor based on an electret film, which includes a stator 1 , a rotor 7 and a rotating shaft 21 .

[0033] The upper part of the stator is provided with a first brush 2 for connecting the DC high voltage negative pole and a second brush 3 for connecting the DC high voltage positive pole. The upper surface of the stator 1 is pasted with a first electret film 4 and a second brush. Two electret films 5, the first electret film 4 and the second electret film 5 have the same area, and are respectively symmetrically attached to the left half and the right half of the upper surface of the stator 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com