Cream filling and forming device for bread processing and using method of cream filling and forming device

A forming device and cream technology, applied in application, dough handling, oven loading/unloading, etc., can solve the problems of long time-consuming, inaccurate, dry and hard bread, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

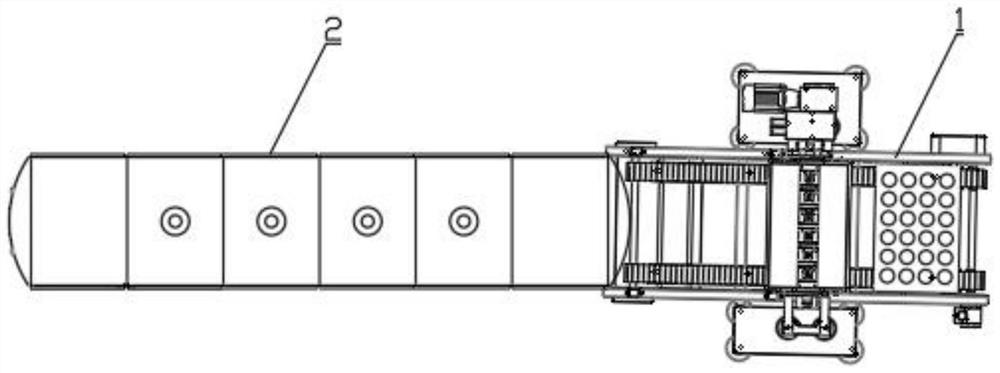

[0036] see Figure 1-7 As shown, a butter filling and forming device for bread processing, including a filling mechanism 1 and a forming mechanism 2;

[0037] The filling mechanism 1 and the forming mechanism 2 are arranged side by side, and the discharge end of the filling mechanism 1 is connected to the feeding end of the forming mechanism 2;

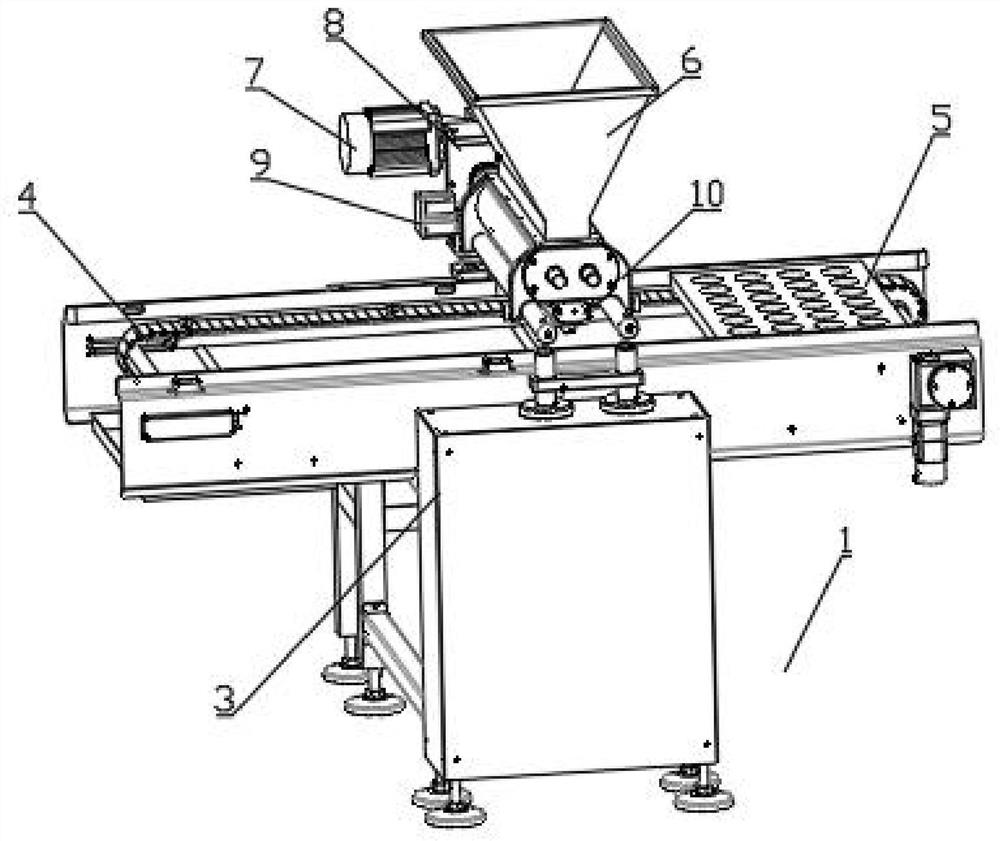

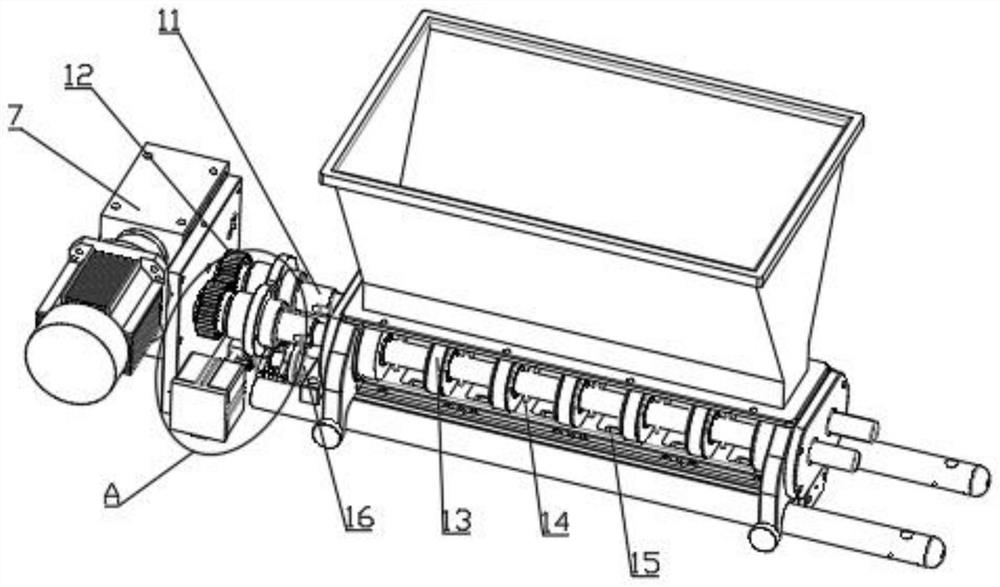

[0038] The filling mechanism 1 includes a support seat 3, a first conveyor belt 4, a mold plate 5, a feeding funnel 6, a first motor 7, a transmission box 8, a first cylinder 9, a filling cavity 10, a stirring shaft 11, a first gear 12, and an isolation plate 13. Stirring rod 14, discharge hole 15, discharge pipe 16, hydraulic cylinder 17, gear bar 18, second gear 19, support seat 3 is a T-shaped structure, and the top of support seat 3 is provided with a first conveyor belt 4, supporting A filling chamber 10 is arranged above the middle part of the seat 3, and a feeding funnel 6 is arranged on the top surface of the filling chamber ...

Embodiment 2

[0052] The difference from Example 1 is: the first step: put the unbaked cup-shaped bread into the mold cavity in the mold plate 5, add the cream into the feeding funnel 6 and then cover the cover plate, and start the first conveyor belt 4 Move the mold plate 5 into the filling cavity 10, start the first cylinder 9 to work, drive the gear bar 18 to work, and drive the second gear 19 and the discharge pipe 16 to rotate through the meshing effect of the gear bar 18 and the second gear 19, Make the through hole of the discharge pipe 16 communicate with the discharge hole 15, so that the butter in the feeding funnel 6 is added into the cup-shaped bread through the discharge hole 15, and at the same time, start the first motor 7 to work, because the transmission box 8 is side by side Two sets of stirring shafts 11 are provided, one end of the stirring shaft 11 extends into the filling chamber 10, and is rotatably connected with the filling chamber 10, the other end of the stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com