Staple food noodles suitable for diabetics to eat and processing method thereof

A processing method and diabetes technology, applied in the field of food technicians, can solve the problems of high coarse grain content, low glycemic index, etc., and achieve high yield, smooth taste, and simple cooking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

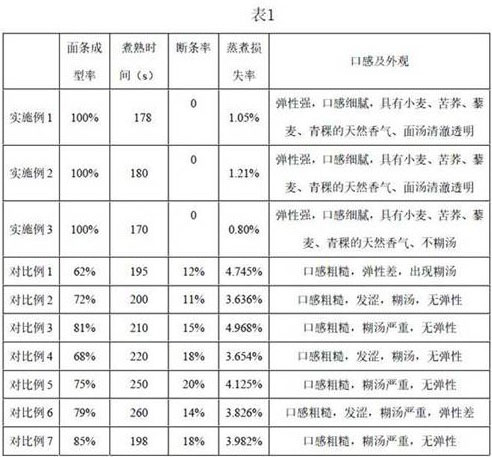

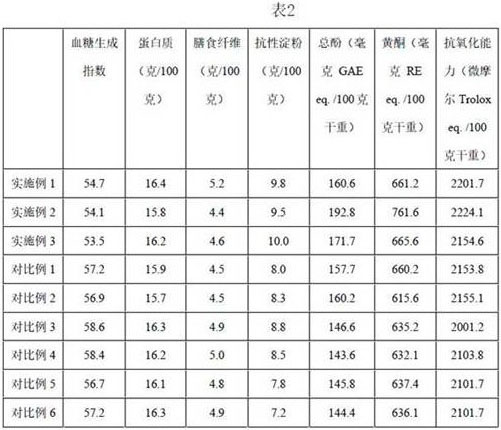

Examples

Embodiment 1

[0033] A spiral noodle suitable for diabetics, comprising the following ingredients in parts by weight: 40 parts of hard wheat flour, 25 parts of tartary buckwheat flour, 5 parts of quinoa flour, 10 parts of highland barley flour, 10 parts of wheat germ powder, and 6 parts of wheat dietary fiber , 7 parts of gluten powder.

[0034] The average particle diameter of the durum wheat flour, tartary buckwheat flour, quinoa flour, highland barley flour, wheat germ powder and gluten powder is 80 mesh; the average particle diameter of the wheat dietary fiber is 300 mesh.

[0035] A kind of processing method of above-mentioned staple food noodles, adopts following steps:

[0036] (1) Pre-cooking tartary buckwheat powder with a mass percentage of 2.5 parts, the pre-cooking condition is 120°C, the time is 120 seconds, and passed through an 80-mesh sieve;

[0037] (2) 3 parts of highland barley powder are pre-cured, the pre-curing condition is 120°C, the time is 120 seconds, and sieved t...

Embodiment 2

[0047] A kind of oblique tube noodle suitable for diabetic patients, which contains the following ingredients in parts by weight: 45 parts of durum wheat flour, 45 parts of tartary buckwheat flour, 15 parts of quinoa flour, 5 parts of highland barley flour, 5 parts of wheat germ powder, and 3 parts of wheat dietary fiber 1 part, gluten powder 1 part.

[0048] The average particle diameter of the durum wheat flour, tartary buckwheat flour, quinoa flour, highland barley flour, wheat germ powder and gluten powder is 80 mesh; the average particle diameter of the wheat dietary fiber is 300 mesh.

[0049](1) 45 parts of tartary buckwheat powder were pre-cured, the pre-curing condition was 155°C, the time was 60 seconds, and sieved through an 80-mesh sieve;

[0050] (2) 10.5 parts of quinoa flour are pre-cured, the pre-curing condition is 120°C, the time is 120 seconds, and sieved through an 80-mesh sieve;

[0051] (3) 5 parts of highland barley powder are pre-cured, the pre-curing ...

Embodiment 3

[0061] A shell noodle suitable for diabetics, comprising the following ingredients in parts by weight: 42 parts of hard wheat flour, 35 parts of tartary buckwheat flour, 10 parts of quinoa flour, 8 parts of highland barley flour, 8 parts of wheat germ powder, and 4 parts of wheat dietary fiber , 4 parts of gluten powder.

[0062] The average particle diameter of the durum wheat flour, tartary buckwheat flour, quinoa flour, highland barley flour, wheat germ powder and gluten powder is 80 mesh; the average particle diameter of the wheat dietary fiber is 300 mesh.

[0063] A processing method for the above-mentioned shell surface, adopting the following steps:

[0064] (1) Pre-cure 20 parts of tartary buckwheat flour at 145°C for 80 seconds and sieve through an 80-mesh sieve;

[0065] (2) Pre-cure 5 parts of quinoa flour at 120°C for 120 seconds and sieve through an 80-mesh sieve;

[0066] (3) 5 parts of highland barley powder are pre-cured, the pre-curing condition is 110°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com