Screw rod supporting steel ball valve sleeve combined electromagnetic valve structure

A screw rod and solenoid valve technology, applied in the direction of multi-way valves, valve devices, valve details, etc., can solve the problems of large leakage, achieve the effects of reducing leakage, improving work reliability, and reducing processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

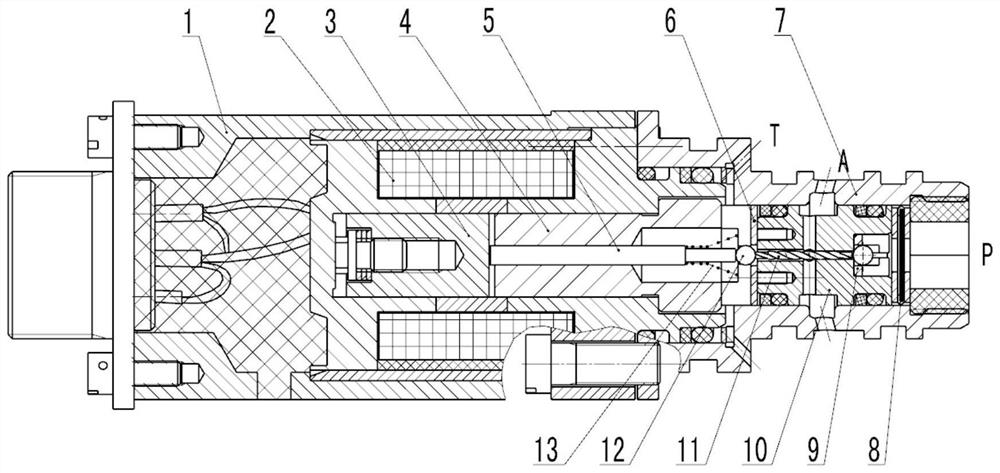

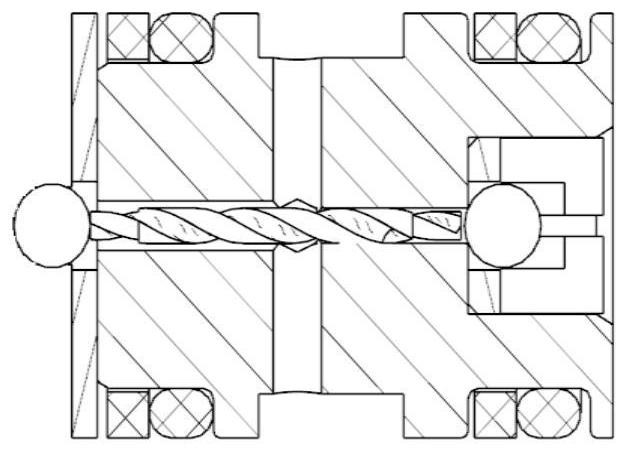

[0016] combine figure 1 and figure 2 Describe this embodiment, a screw-rod supporting steel ball valve sleeve combination solenoid valve structure, including an outer cover 1, an electromagnet assembly 2, an armature assembly 3, a stopper 4, a push rod 5, a left valve sleeve 6, a housing 7, and a filter screen Assembly 8, right valve sleeve 9, valve seat 10, screw rod 11, steel ball 12 and tower spring 13;

[0017] When the solenoid valve is energized, the armature assembly 3 overcomes the tower spring 13 to move to the right under the force of the electromagnet assembly 2 and engages with the stop iron 4, and closes the gap between the left steel ball and the left valve sleeve 6 under the action of the push rod 5 Open the passage between the right valve sleeve 9 and the right steel ball, and the fuel medium enters the control chamber of the screw rod 11 after being filtered by the filter assembly 8 from the P port, so that the A port and the P port are connected, and the A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com