Equipment for detecting air tightness of waders

A technology of air tightness and equipment, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of increasing the detection error rate, time-consuming and laborious, gas escape, etc., Achieve increased stability and accuracy, enhanced speed and observation, and better contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

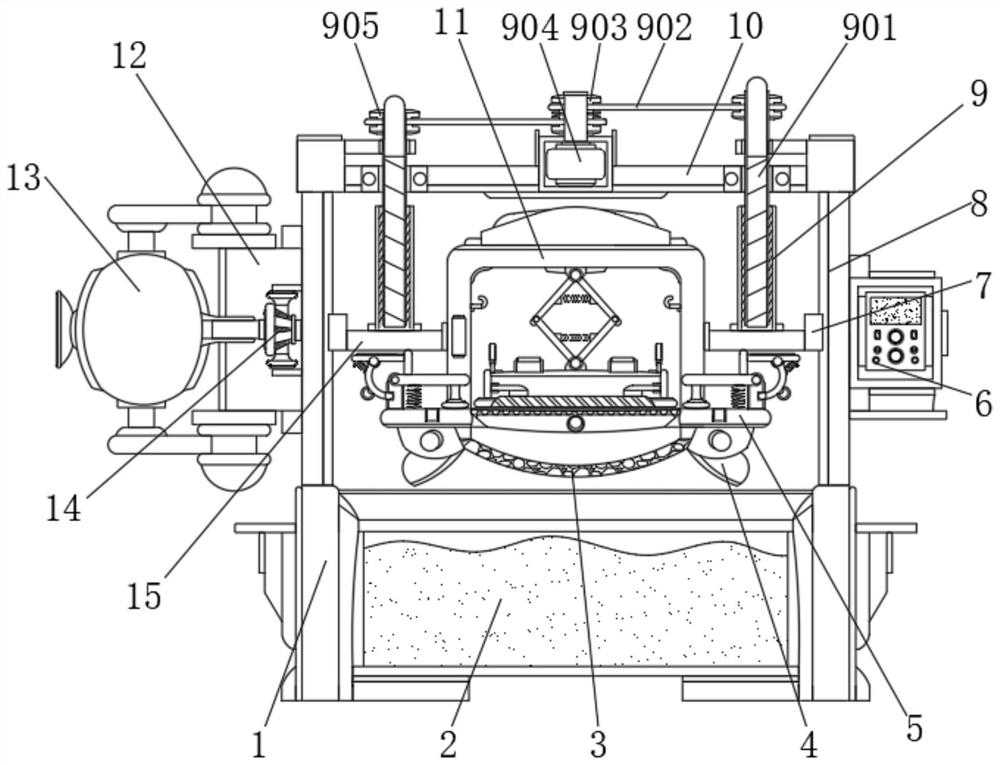

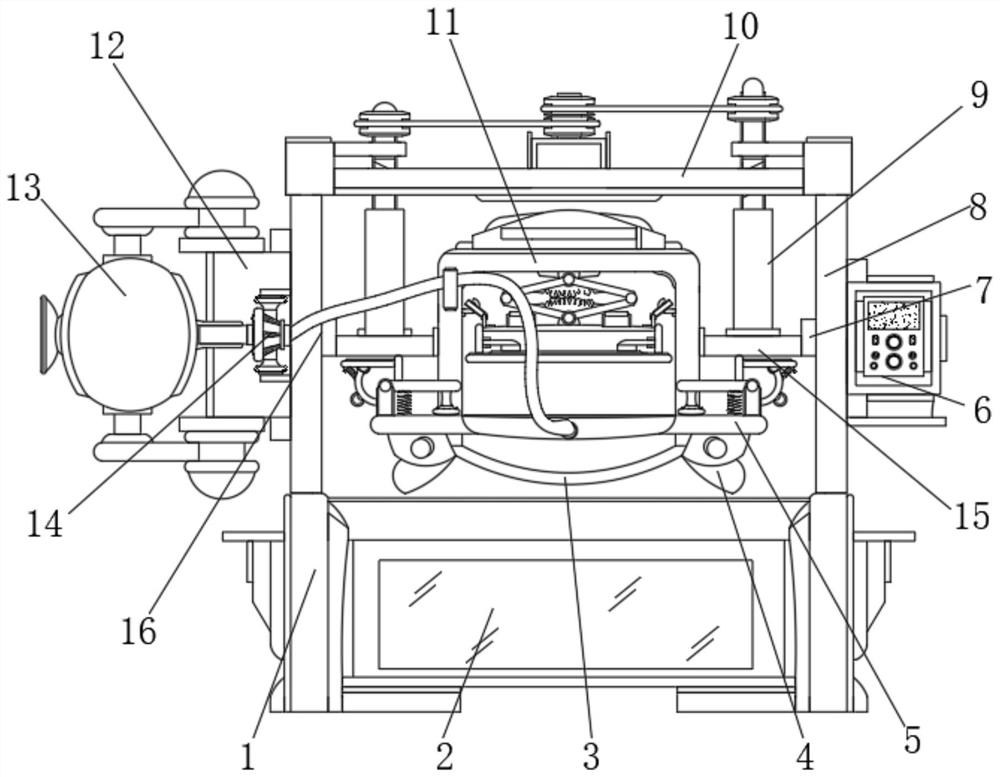

[0034] Example 1, such as image 3 As shown, during the air tightness test of the water trousers, the connecting seat 117 can be pulled to drive the pressing plate 119 and the water-changing ink layer 118 to rise, and the hinged cooperation of the hinged block B116, the hinged rod 115 and the hinged block A113 is used to make the connecting seat 117 lift, and drive the spring 114 to stretch, which is convenient for subsequent automatic reset. After the connecting seat 117 is pulled to the designated position, the movable hanging ring 111 is hung into the hook 112 to engage, so that the position of the connecting seat 117 can be fixed. The table top of the detection platform 5 can be in an empty state, which is convenient for the clamping and installation of the water trousers. When the absorption and discoloration function of the hydrochromic ink layer 118 needs to be used, it can be put down again to increase the flexibility of the device.

Embodiment 2

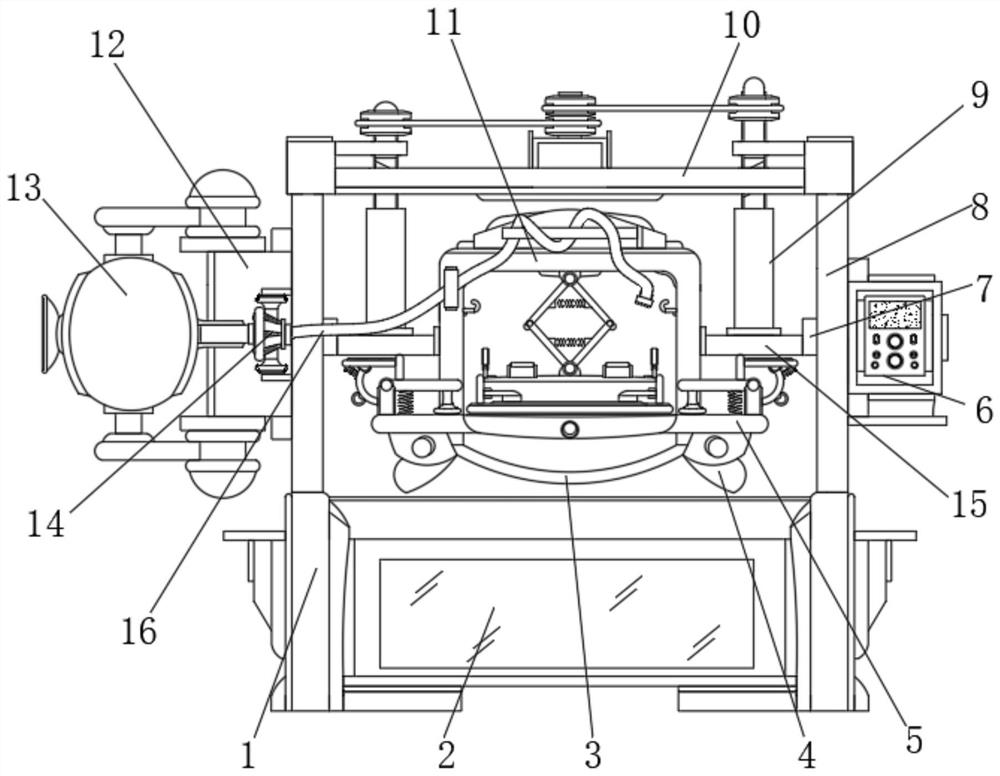

[0035] Example 2, such as Figure 5 As shown, when the water trousers need to be clamped, first pull the arc-shaped clamping plate 195 to cancel the fixation with the clamping groove 194, and compress the stainless steel spring B196, and then pull the arc-shaped clamping plate 195 downward to drive the L-shaped mounting plate 197 And the hinged plate 19 is opened under the hinged cooperation of the hinged seat 193, so that the pressing suction cup 198 is disengaged from the clamping and fitting of the detection table 5, and the stainless steel spring A192 is stretched. The ventilation part is folded and stuck into the groove 191, and then the arc clip 195 is released, the hinge plate 19 and the pressing suction cup 198 are automatically reset by the elastic restoring force of the stainless steel spring A192, and the water trousers are clamped and fixed, and the arc is manually moved The clamping plate 195 snaps into the clamping groove 194 to fix the position of the L-shaped m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com